Dive deep into the world of laser cutting, where precision meets innovation. Laser cutting, a technique revered by industries for its accuracy and efficiency, has multiple facets. Each type of laser cutting method has its advantages, challenges, and ideal applications. Let’s explore these methods in detail to find the perfect fit for your needs.

What is Laser Cutting?

Laser cutting is a non-contact process that uses a laser beam to slice materials. It is characterized by its precision, speed, and versatility, making it a popular choice for various industries. The term ‘laser’ stands for “Light Amplification by Stimulated Emission of Radiation.” Essentially, it involves the use of a concentrated laser beam to melt, burn, or vaporize the material, resulting in cleanly cut edges.

What are the Different Types of Laser Cutters?

Delving deeper, we encounter diverse laser cutting machines, each with its unique properties and applications.

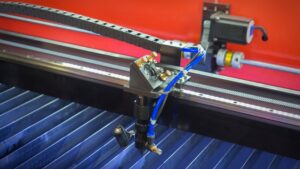

Fiber Laser Cutters

These powerful machines, the fiber laser cutters, don’t merely boast of their prowess without reason. The fiber laser cutting anatomy traces back to banks of diodes, ‘fibered’ together to bring forth a high-intensity laser beam, which is truly ideal for cutting.

In fact, these diodes, housed in compact modules, generate light that is channeled and amplified through fiber-optic cables. When this light emerges from the fiber-optic cables, it retains its power and quality, and with proper adjustments, becomes tailored for material cutting.

Fiber laser cutters make it possible to trim objects with a depth of less than 5 mm more quickly and efficiently than CO2 laser cutters.

A fiber laser typically has a long operational life of a minimum of 25,000 laser hours and requires no servicing. Fiber laser cutters can therefore create powerful and steady rays and offer a far longer lifespan compared to the other different sorts of lasers. They share the equivalent average output as CO2 lasers but can achieve levels that are 100 times greater.

Fiber lasers can operate in a constant projectile, quasi-continuous beam, or pulsed modes, providing them with a variety of functionality. The MOPA is a fiber laser technology subtype with variable pulse lengths. Which gives the MOPA laser the title of the most adaptable laser, with a wide range of potential uses.

Benefits

Fiber lasers have paved their way into the industry by presenting several compelling benefits:

- High Energy Efficiency: The very foundation of a fiber laser lies in its efficiency. With a wall plug efficiency surpassing 40%, these lasers consume considerably less power.

- Precision in Cutting: Especially on reflective materials, the precision is unmatched, making it a coveted tool in industries seeking impeccable cuts.

- Cost-Effectiveness: While the initial investment might seem hefty, the lower operating costs compared to other lasers balance the scales.

Drawbacks

But with the glittering benefits, there are shadows cast by certain limitations:

- Material Limitation: The specific wavelength means they’re generally more apt for thinner material types.

- High Initial Investment: Setting up a fiber laser cutting machine requires a significant upfront capital.

Applications and Supported Materials

It’s imperative to know where fiber lasers shine brightest. Their prowess is witnessed in materials like:

- Metals: Notably in stainless steel, copper, aluminum, and brass.

- Ceramics: Crafting intricate patterns and designs.

- Carbon-fiber-reinforced Polymers: Utilized for specialized industrial applications.

Cost and Maintenance

The financial spectrum for fiber lasers usually oscillates between $20,000 to $500,000, contingent on power and brand. Maintenance, albeit minimal, is crucial:

- Cleaning the cutting head and lens regularly ensures the beam’s quality.

- An annual inspection of the power source keeps the machine’s heart in check.

- Monitoring fiber optic cables for wear ensures uninterrupted operations.

CO2 Laser Cutters

When we speak of CO2 laser cutters, we refer to machines with a pedigree rooted in a gas mixture dominated by carbon dioxide. These laser cutters have earned their stripes due to their aptitude for a vast array of materials. Unlike the compact diode setup in fiber lasers, the CO2 resonator is substantial.

It relies on electricity mingling with a blend of gases to produce the laser beam. Intensity is achieved through mirrors, but as the beam journeys towards the lens, traversing multiple cooled mirrors, there’s an inevitable power and quality drop.

The strongest CO2 lasers can produce many Kilowatts of energy for industrial machinery, although they are the only exception to the rule. A common CO2 laser for cutting has a strong range of between 25 and 100 Wattage and a frequency of 10.6 micrometers.

Benefits

The CO2 laser cutters come equipped with their own set of advantages:

- Versatility: A salient feature, enabling them to cut both non-metal and metal materials.

- Excellent Beam Quality: Despite the power loss during transit, the beam quality remains top-notch.

- High-Speed Cutting: The processing time of the material, especially tubes, is commendable, leading to faster production of finished parts.

Disadvantages

But like any technology, they have their share of challenges:

- Elevated Operating Costs: The constant need for gas refills bumps up the operating costs.

- Maintenance Rigor: To ensure optimal functioning, regular maintenance becomes a mandate.

Applications and Supported Materials

The CO2 laser cutters are no slouches when it comes to versatility:

- Metals: They comfortably handle mild steel and stainless steel.

- Non-metals: Their expertise spans across wood, acrylic, glass, leather, paper, and various plastics. Additionally, it helps while working with materials like animal skin, textiles, wallpapers, and others. The preparation of foods like cheeses, nuts, and different vegetation has also been done by CO2 lasers.

Cost and Maintenance

A CO2 laser cutter’s price bracket ranges from $8,000 to $50,000, influenced by size and capabilities. Maintenance for these machines is slightly demanding:

- Regular lens and mirror checks are imperative to maintain the beam’s quality.

- Gas refills and checks are quintessential for uninterrupted operations.

- Keeping the moving parts clean is vital to prevent performance hindrances.

Nd:YAG/Nd:YVO Lasers

Among the main types of lasers, Nd:YAG (Neodymium doped Yttrium Aluminum Garnet) and Nd:YVO (Neodymium doped Yttrium Ortho Vanadate) lasers, often called crystal laser cutters, stand out. As one delves into the nuances of laser cutting technology, it becomes evident that these solid-state lasers have carved a niche for themselves in various industries, thanks to their versatility and power.

Benefits

Understanding the advantages of Nd:YAG/Nd:YVO lasers brings to light why many industries prefer them for precision work. Primarily, these lasers are heralded for their engraving and marking capabilities. Their power density is so intense that they can engrave even the hardest materials with great precision.

Their ability to be transmitted through fibers enhances their versatility. It means that they can deliver their laser beam to areas that might be challenging for other types of lasers. This transmission ensures a high degree of precision, which is paramount in industries where minute details matter.

- Ideal for engraving and marking: Their power and precision make them the tool of choice for these tasks.

- Ability to be transmitted through fibers: It enhances their reach and versatility.

- Highly precise: This ensures that the base material retains its integrity during the laser cutting process.

Disadvantages

While Nd:YAG/Nd:YVO lasers offer unparalleled precision, they also come with certain limitations. The high initial costs can be prohibitive for smaller businesses or those just venturing into laser cutting. Furthermore, their versatility in terms of materials isn’t all-encompassing.

- High initial costs: Acquiring these laser cutting machines can put a significant dent in one’s budget.

- Limited to specific material types: They might not be suitable for every material in the industry.

Applications and Supported Materials

When it comes to applications and materials, Nd:YAG/Nd:YVO lasers shine in certain domains. They’re especially adept at handling metals such as titanium, nickel, and steel. Beyond metals, they also have proficiency in working with ceramics and specific plastics.

- Metals: Including Titanium, nickel, steel – materials often found in aerospace applications and intricate machinery.

- Ceramics: A domain where precision is key, and these lasers deliver it impeccably.

- Certain plastics: Not all plastics are amenable to this type of laser, but those that are, like polycarbonate, benefit from its precision.

Cost

The financial aspect is often a determinant in choosing a laser cutting machine. Nd:YAG/Nd:YVO lasers generally range between $60,000 to $200,000. Factors influencing this range include the power source, brand, and additional features. When considering the cost, it’s also wise to factor in the unparalleled precision and capabilities they offer.

Required Maintenance

Maintaining any sophisticated machinery is paramount to ensure its longevity and performance. For Nd:YAG/Nd:YVO lasers, this means:

- Routine cooling system check: Ensuring the cooling system is functioning optimally prevents overheating.

- Diode replacements as needed: Diodes are integral to the functioning of the laser, and their periodic replacement ensures uninterrupted operations.

- Periodic recalibration: This ensures the laser beam remains accurate, maintaining the quality of the cuts.

Direct Diode Lasers

Venturing into the realm of Direct Diode Lasers, we find devices known for their exceptional efficiency. They stand out among the main types of lasers as they use diodes directly to produce the desired wavelength. For those diving deep into laser cutting processes, Direct Diode Lasers offer a combination of speed and compactness.

Benefits

Direct Diode Lasers are rapidly gaining popularity for several reasons. Their superior electrical efficiency makes them a cost-effective choice in the long run. Their compact design ensures they fit well even in places with limited space. The quick processing times further add to their allure, making them a favorite among industries where time is of the essence.

- Superior electrical efficiency: Reduces energy consumption, translating to lower operating costs.

- Compact design: Ideal for setups with space constraints.

- Quick processing times: Increases productivity and reduces downtime.

Disadvantages

While Direct Diode Lasers bring several benefits to the table, they’re not without their disadvantages. One primary concern is their beam quality, which might not match up to other laser types. Moreover, they’re restricted in terms of cutting thickness, which can limit their applications.

- Lower beam quality compared to other types: Might not be suitable for jobs demanding extremely high precision.

- Restricted cutting thickness: Might not work well for materials that are too thick.

Applications and Supported Materials

Direct Diode Lasers have specific areas where they excel. When it comes to metals, they’re particularly effective with thin sheets of steel and aluminum. Beyond metals, plastics like Polymethylmethacrylate and polycarbonate are well-suited to these lasers.

- Metals: Thin sheets of steel, aluminum – common in sheet metal fabrication.

- Plastics: Polymethylmethacrylate, polycarbonate – materials often used in manufacturing and construction.

Cost

The price range for Direct Diode Lasers hovers between $50,000 to $150,000. The variation in cost can be attributed to factors like power, brand reputation, and additional features.

Required Maintenance

Regular maintenance ensures the longevity and efficient performance of Direct Diode Lasers. Key maintenance tasks include:

- Periodic diode replacement: Ensures the laser source remains effective.

- Regular cleaning of the beam delivery optics: Clean optics ensure a focused and powerful beam, crucial for precision cuts.

What Are the Things To Consider when Choosing the Laser Cutting Type?

- Material type and thickness: Laser cutting relies heavily on the material’s properties. Certain types of lasers, like fiber lasers, are more efficient at cutting metals like stainless steel or aluminum, while CO2 lasers excel at cutting non-metals like wood, acrylic, and paper. Understanding the material thickness is equally vital. For instance, thick materials might require lasers with a higher power range.

- Desired precision and edge quality: The type of laser you choose can affect the precision of your cuts. Solid state lasers, like neodymium-doped yttrium aluminum garnet (Nd:YAG) and neodymium-doped yttrium ortho vanadate (Nd:YVO4), are known for their precision and quality finishes.

- Production speed requirements: Fiber lasers, with their high-speed capabilities, are particularly well-suited for applications demanding rapid sheet metal fabrication. Comparatively, CO2 lasers might not be as fast but offer versatility.

- Initial investment budget: The upfront cost can be a decisive factor. For instance, diode lasers are typically less expensive than their CO2 or fiber laser counterparts.

- Operating and maintenance costs: Maintenance requirements can vary across laser types. While fiber lasers are virtually maintenance-free, CO2 laser cutters may require regular upkeep due to their complex gas mixture and mirror control mechanisms.

- Intended application: Laser cutting is not just about slicing materials. Depending on your need – be it engraving, drilling, or slicing – certain lasers might be more suitable. For example, CO2 lasers provide an excellent engraving process on materials like wood and glass.

- Power consumption and energy efficiency: CO2 lasers, despite their capabilities, have higher energy consumption compared to fiber lasers. An understanding of power consumption can significantly impact operating costs, especially for large-scale operations.

- Work environment and available space: The space requirement can vary based on the laser type. While the CO2 resonator takes up more space, fiber laser modules are compact, often the size of a briefcase.

Conclusion

Laser cutting, an ever-evolving technology, offers an array of choices catering to diverse needs. By understanding the intricacies of each type, one can make an informed decision, ensuring efficient and precise outcomes.

FAQs

1. What is the most popular laser-cutting type?

The CO2 laser cutter, with its versatility and broad range of applications, remains one of the most popular laser cutting types. Suitable for both metals and non-metals, its wide spectrum of uses, from engraving to sheet metal fabrication, has made it a favored choice across industries.

2. What is the most universal laser-cutting type?

Fiber lasers are often considered the most universal laser cutting type. Their ability to efficiently cut various metals, coupled with their high-speed processing and superior wall plug efficiency, makes them a go-to choice for diverse applications. Their adaptability is further accentuated by their capability to work with reflective materials, a feature not all laser types offer.

3. Which type of laser cutter requires the least maintenance?

Fiber laser cutters stand out for their minimal maintenance requirements. Unlike CO2 lasers, which demand regular check-ups due to their gas circulation and mirror control systems, fiber lasers are virtually maintenance-free. This makes them an attractive option for manufacturers seeking reduced operational disruptions and costs.