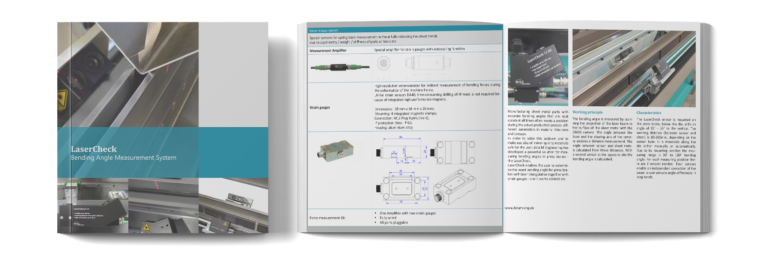

Working principle

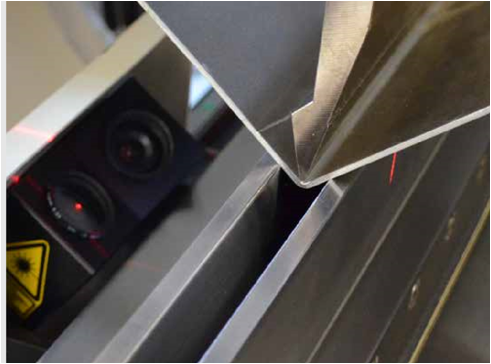

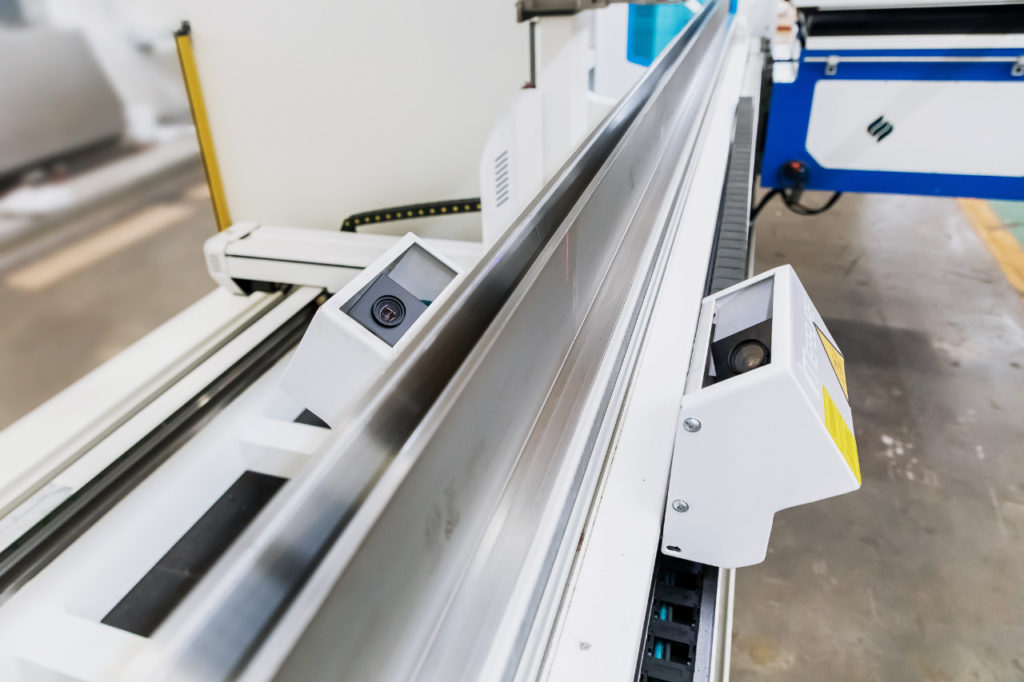

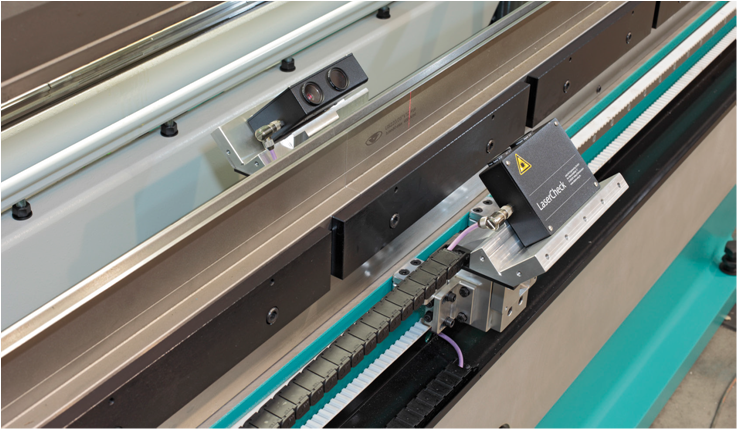

The bending angle is measured by scanning the projection of the laser beam to the surface of the sheet metal with the CMOS camera. The angle between the laser and the viewing axis of the camera enables a distance measurement. The angle between sensor and sheet metal is calculated from these distances. With a second sensor at the opposite site the bending angle is calculated.