ACCURL

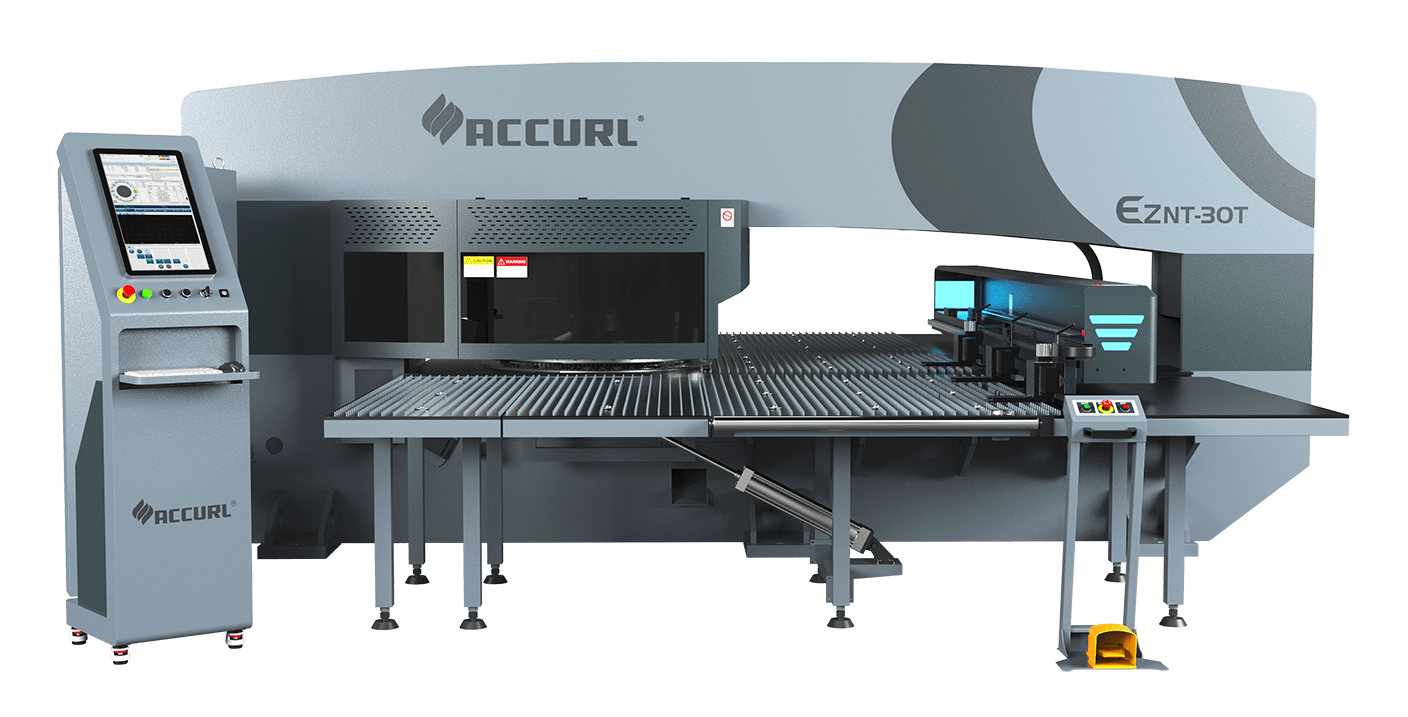

Electro Servo Turret Punch Press - ES NT Series

Electro Servo Turret Punch Press

Includes Following Features And Configuration

Flexible

Reliable

Profitabie

User Friendly

Electro Servo Turret Punch Press - ES NT Series

ACCURL‘s Newly launched ES NT Series Electro Servo CNC Punch Press 30 ton with advanced REXROTH AC Servo drive technology. and featured with high speed, high precision, energy saving, and low noise. the ES NT Series CNC turret punching machine was the newly developed can use with Multi Index Tools equipped, introduced by AccurlUSA professional R &D and production teams who have been dedicated to machineries for decades. The result is unmatched performance, superior reliability, and lower operating costs.

Float the following content above the background:

- User friendly REXROTH MTX Series CNC Controller unit

- Full electro RAM Servo Transmission System

- ACCURL® automatic repositioning clamps and loading switches

- Suitable for 1250x2500mm sheets

- 32 Station turret with 2B Auto-index stations

- Industry 4.0 of Productivity Monitor

- RADAN® Software for using wheel and forming tools

- Hardened, grinded tools and clamps for quick tools adjustment

- Brushed table with automatic ball bearing.

- Auto repositioning clamps.

- Clamp safety check system.

- Tools stuck safety system.

Advanced Servo System

Providing energy efficiency, mineral oil does not require, green, Servo control Punching Machine

- Advanced CNC Servo system with pressure valve to precisely control the speed, volume and pressure of oil flow.

- To control the RAM stroke distance on both ends, hence the height and depth of each punch becomes programmable with 0.1mm accuracy.

- Uniquely designed Machine structure ensures less preventive maintenance

- The AC punch servo motor can be programmed for various applications.

- High speed applications.

- Low noise applications.

- Forming applications.

REXROTH Servo Transmission Technology

- Advanced REXROTH CNC Servo system to control the RAM stroke distance on both ends, and depth of each punch becomes with 0.01mm accuracy.

- The AC punch servo motor can be programmed for various applications.

- High speed applications.

- Low noise applications.

- Forming applications.

- The punch servo utilizes a direct drive gearbox that supplies power and speed,the servo allows the user to steplssly adjust the punch stroke and accommodate any pressure curve requirements.

Flexible Turret Concepts

- The ACCURL is compatible with thick turret tooling,the wide variety of specialty tools com-bined with the programmable ram means the ACCURL can deliver for any application.

- The auto indexable stations have a dual lead worm structure.the worm gear’s side clearance can be controlled under 0.001mm and can be adjusted for wear.

- The turret comes with 4 main layouts from 32 stations to 52 and up to 4 auto indexing stations.

- Permanently engaged auto index drive system reduces errors and avoids downtime.

- Each station can be fitted with various brand tools, such as Mate and Wilson.

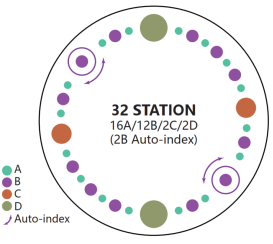

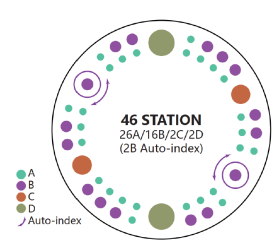

32 Stations 2 Auto index

ACCURL entry level turret offers a full set of tooling with two auto indexing stations.

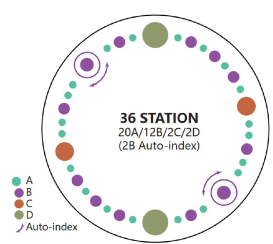

36 Stations 2 Auto index

With one flex station,the 36 station turret can be upgraded with an additional auto index B station.

42 Stations 4 Auto index

ACCURL most flexible design comes with four auto indexing stations to offer the most advanced material processing capabilities.

REXROTH Servo Transmission Technology

- Synchronized dual servo motors for controlling the auto index functions.

- 2 B Auto Index Stations for Multi Tools, either 3 B or 8 A.

- Capable of indexing each individual tool within the 3B and 8A Multi Tool set.

- Capable of running wheel, marking, grooving and forming Tooling.

- two alternatives of 32 and 24 stations; in 32 stations models two of them indexable B stations and may include 8A or 3B.

High Quality Forming, Tapping & Wheel Applications

The variable dwell capability at the bottom of the stroke provides for high quality forming. Typical secondary operations for progressive forms, flanges embossments, louvers, etc. can many times be eliminated. With roller wheel technology you are not limited to straight geometries but can produce curved and round configurations Tapping is also possible.

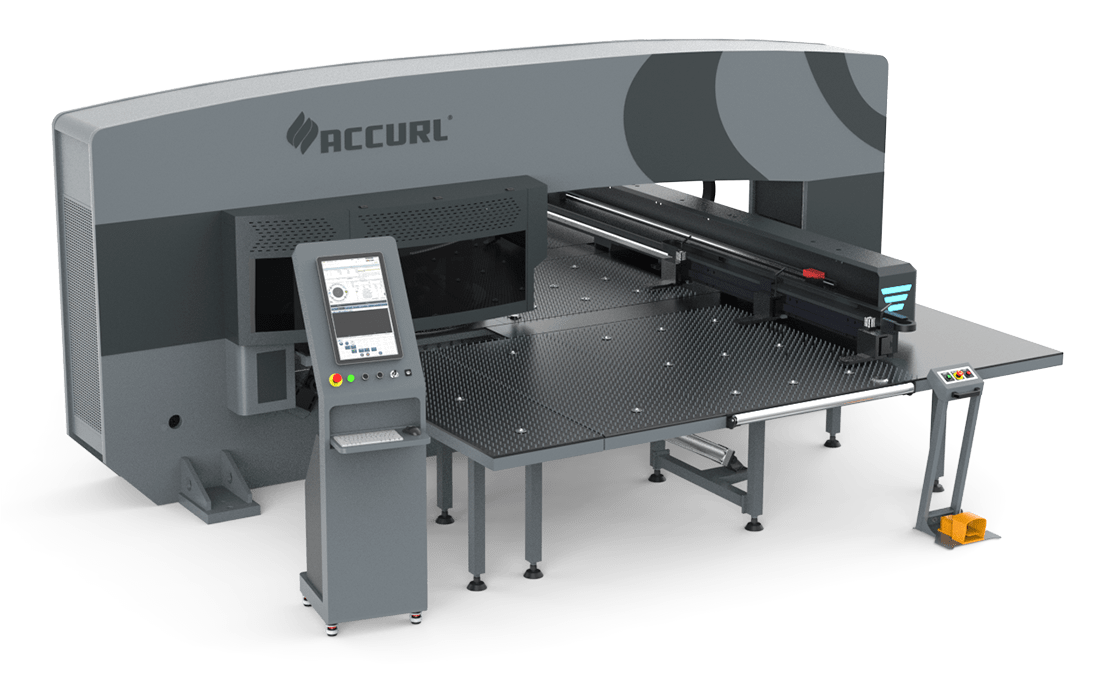

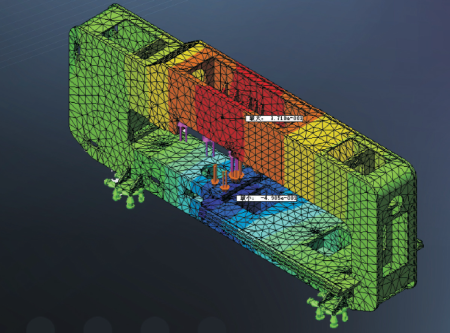

Rigid Press Frame

- Improved stability in the punching process using 12.5% thicker material for the press side frames and improved stiffness of base component.

- O-type closed integral welding press frame special for servo punch press.

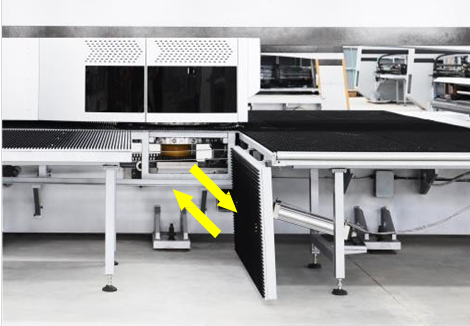

Workchute

- Ball table mainly easy movement of the sheet, brush table is generally for sensitive and soft material punching for not to scratch the sheet.Both is available according to customer demands.

- To evacuate parts during punching also with sorting and stacking capacity.

- The parts chute, small parts up to 400 x 600 mm can be ejected directly into a parts container.

An optional conveyor system. (optional)

Automatic Pneumatic Clamps

- When punching thinner material, one of the problem is to control the sheet movement at non clamping area. To eliminate this matter 3 clamps or more is available.

- Automatic Clamp positioning reduces setup time and errors ,and provides machine runtime flexibility and productivity.

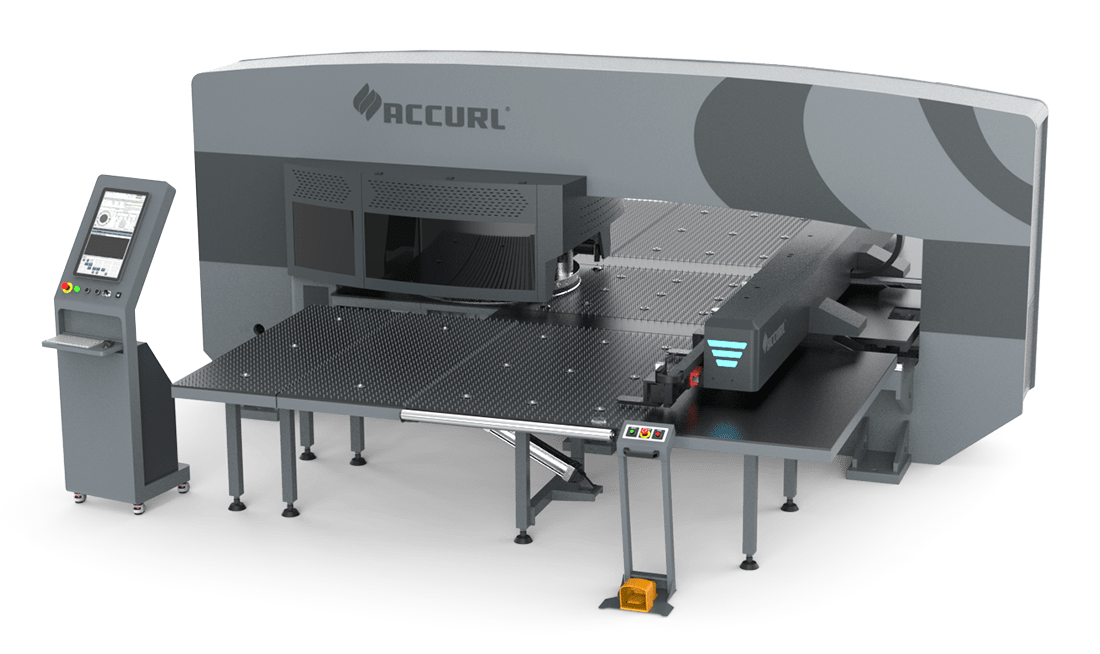

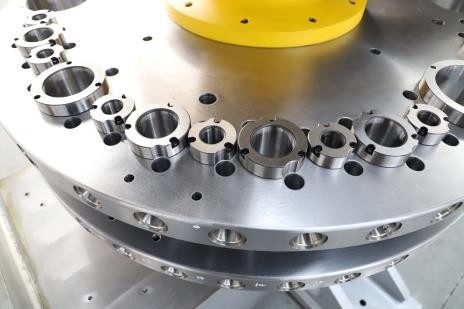

Full Auto Indexed Station

- Tools are rotatable in 0.01° increments enabling the processing of complex shaped parts with the minimum number of tools.

- Tool change takes less than 3 seconds to complete total turret movement and just 0,6 seconds for single tool.

- The turret itself is made of s50C and undergoes rigorous testing.

Precise and High Speed Turret

- The punching head stroke rates of 1200 strokes per minute during punching and 3200 per minute during marking.

- The machine control adjusts stroke travel speed and position.

With its dynamic design, it is possible to obtain speeds of

- 116 m/min in X axis

- 80 m/min in Y axis

- 140 m/min simultaneously

- High acceleration (1g) is possible across the whole working range without any restriction.

REXROTH CNC Control System

The ACCURL turret punch press comes with Rexroth IndraMotion MTX CNC controller

ACCURL®has chosen the very powerful REXROTH CNC Control, which has been specially designed for punchding. IndraMotion MTX and IndraDrive digital drives allow you to maximize the stroke rate of your machine and improve productivity. A process-optimized operating interface and special punching and nibbling functions of the CNC core facilitate programming and keep machine downtime to a minimum.

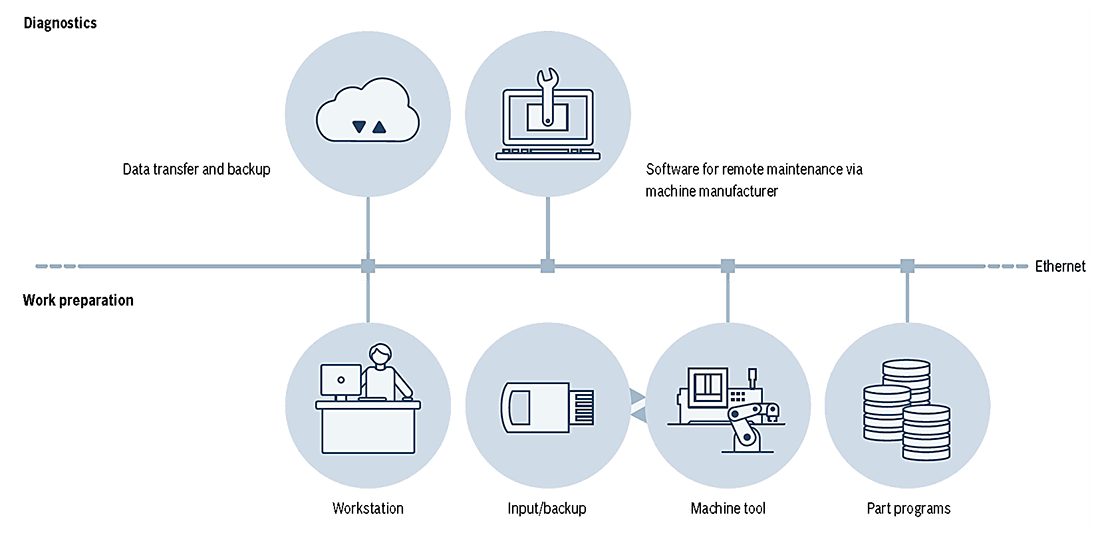

IndraMotion MTX –high-speed CNC machining

Ready for Industry 4.0

The integrated OPC UA server provides access to the control data – all in real time. Thus, the control unit can be combined with MES systems, a data analytics server, or cloud solutions with little eff ort.

REXROTH IndraMotion MTX

high-speed CNC machining

Direct communication

Program processing via networks

- Easy integration of IndraMotion MTX in existing network infrastructures via Ethernet and TCP/IP

- Almost unlimited storage space for CNC programs and data

- Seamless integration of external CNC data in the IndraMotion MTX file system via network drives

- Analyzing the status of the machine and the use of the machine is possible with the Data Analytics Server,a powerful database solution. The easy-to-use, browser-based confi guration and visualization allows the user to concentrate on the essentials - optimizing the process.

- TCP/IP communication allows a connection to be made to an office PC and CNC control system. This, in turn, makes it possible to carry out diagnostics from a control station or perform remote maintenance via the Internet

- Integration of external storage media, for example a USB flash drive, in the file system of the control enables direct selection of CNC programs - with no copying necessary

- Monitoring of the control, drive and sensor data in real time using the OPC UA standard

- Powerful database to store large amounts of data

- Workfl ow system to analyze, optimize and resolve manufacturing problems

- Long-term diagnostics logbook with integrated TOP10 error analysis

- Deployment of pre-processed data for other IT systems like MES, PPM, and Data Analytics via the OPC UA standard

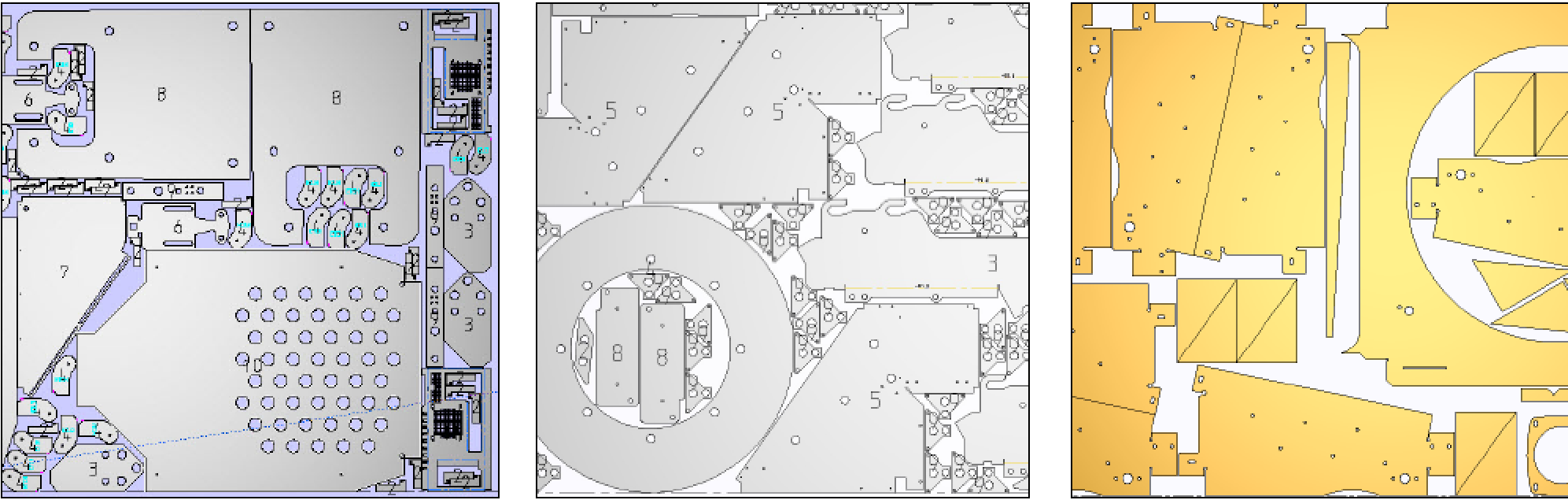

CAD-CAM Nesting Software

ACCURL CNC Punch using software Radprofile Punch CAD / CAM with its own postprocessor. Features like auto nesting and machining, calculating the time, micro-joint, total Punch and more allow ease of Punching.

Radnest analyses the true shape, material and thickness of all components in a batch, separating and sorting automatically, producing high utilisation, manufacturable nests from sheets, off-cuts and remnants, delivering substantial savings in material and improving machine efficiency.

All data for Punching is installed in the technological Radan charts.

This program is designed for nesting and machining and is installed directly on the CNC, without any adjustment to the Punching parameters.

- Preparing a normal Punch

- Punching with pre-piercing

- Sheet metal clearances

- Clearances between parts

- Preparing common Punch

- Edit Punching speeds

- Adding new material to the list

- Using remnant option (saving excess parts of the sheet)

- Marking

- Giving radius at the corners

- Modifying corners to 90 degrees

- Defining Punching technology (Punch1, Punch2)

- Giving micro joint for nested parts

- Changing the length of the entrance properties

- Reporting writings with marking property

- Change Punching direction

- Scale dimensioning

- Combining the intermittent lines

- Film burning for covered stainless steel

- Punch 1, Punch 2, Punch 3, Punch 4 and small hole property changing