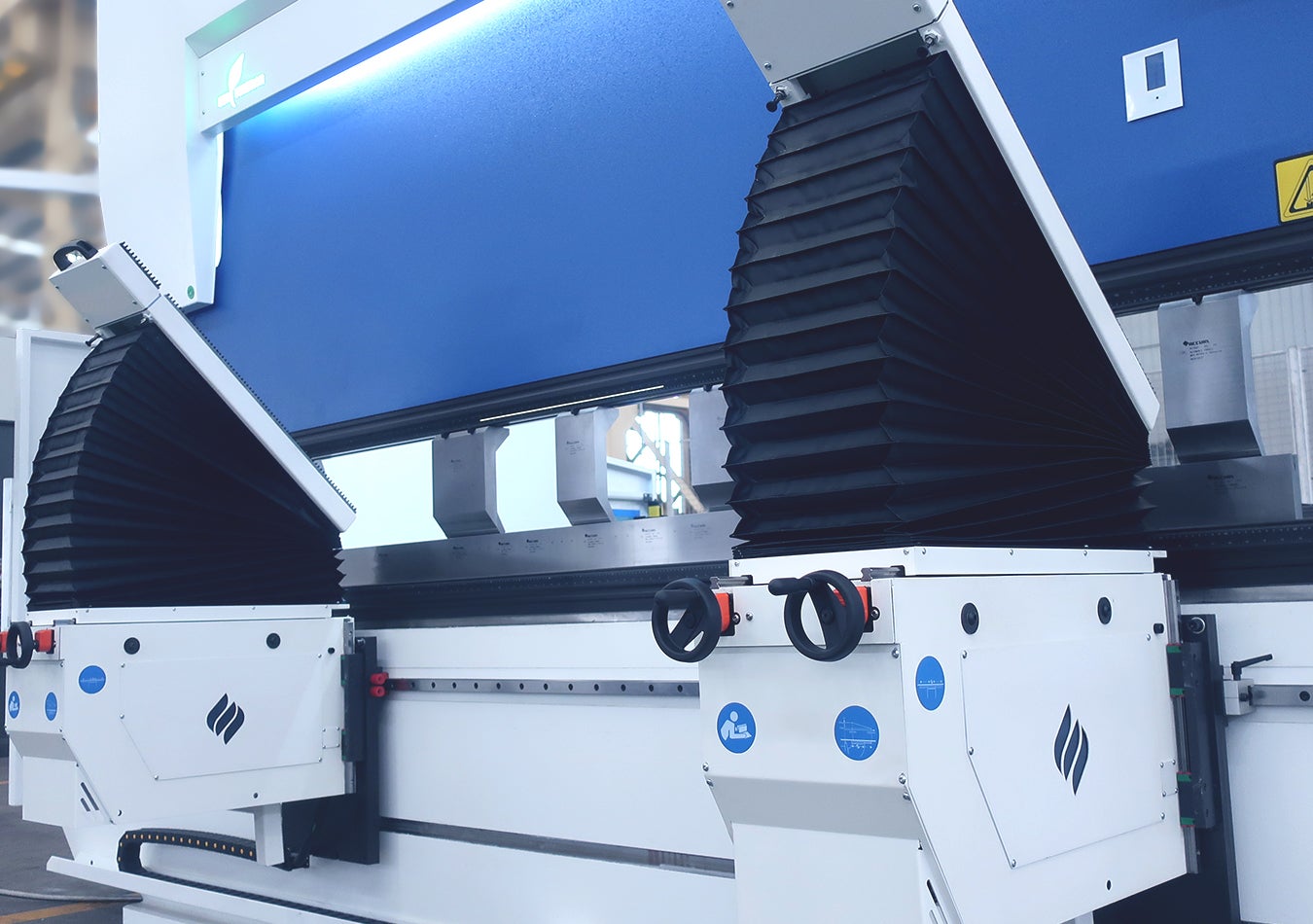

SMART WAY TO INCREASE PRODUCTIVITY

Choose And Configure Your Press Brake

ACCURL is one of the world’s leading Top 10 manufacturers in the field of steel metal working machinery. the Accurl Brand founded in 1988, was the earliest batch sheet metal working machines manufacturer for CNC press brake and fiber laser cutting machine in China.

We aim at making bending and cutting sheet metal a quick, precise and reliable process. We try to make our Clients more productive and competitive.We aim to become the constant point of reference in the theory and practice of press braking and shearing.

ACCURL® top customisation fully configurable following the customer’s need, and the standard range features models with capacities varying from 30 to 2000 ton, this versatility goes from sizing to optional equipment.

The ACCURL is aiming to be effective on its customers’ future improvements and to share big ideas by offering the latest technologies under the most competitive circumstances and forecasting their future requirements.

CNC Control System

ACCURL® has chosen only the most powerful and reliable controls on the market to pair with our press brakes.

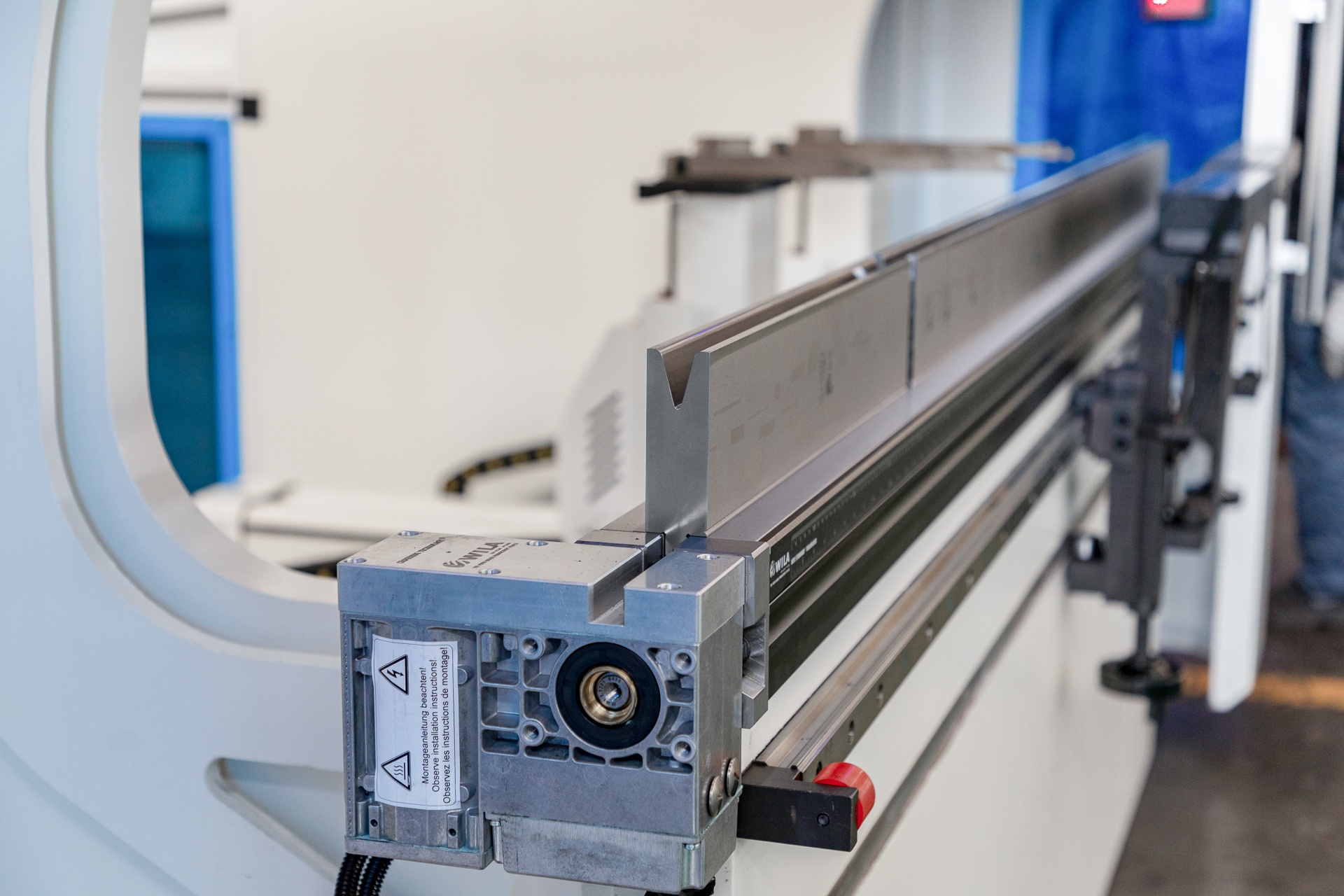

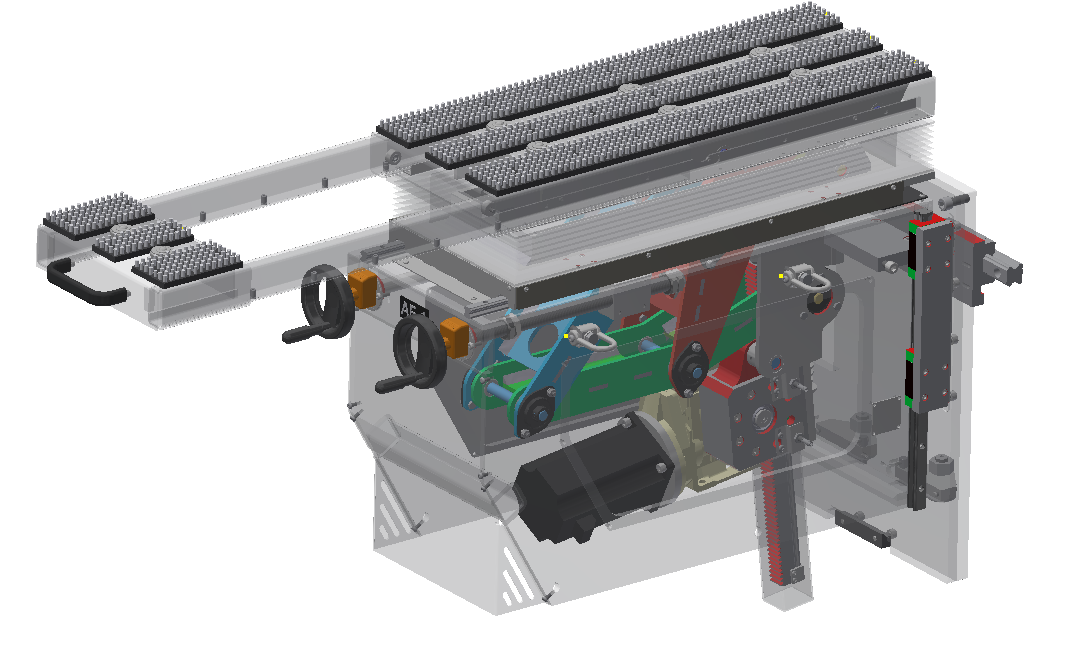

Back Gauge Modification

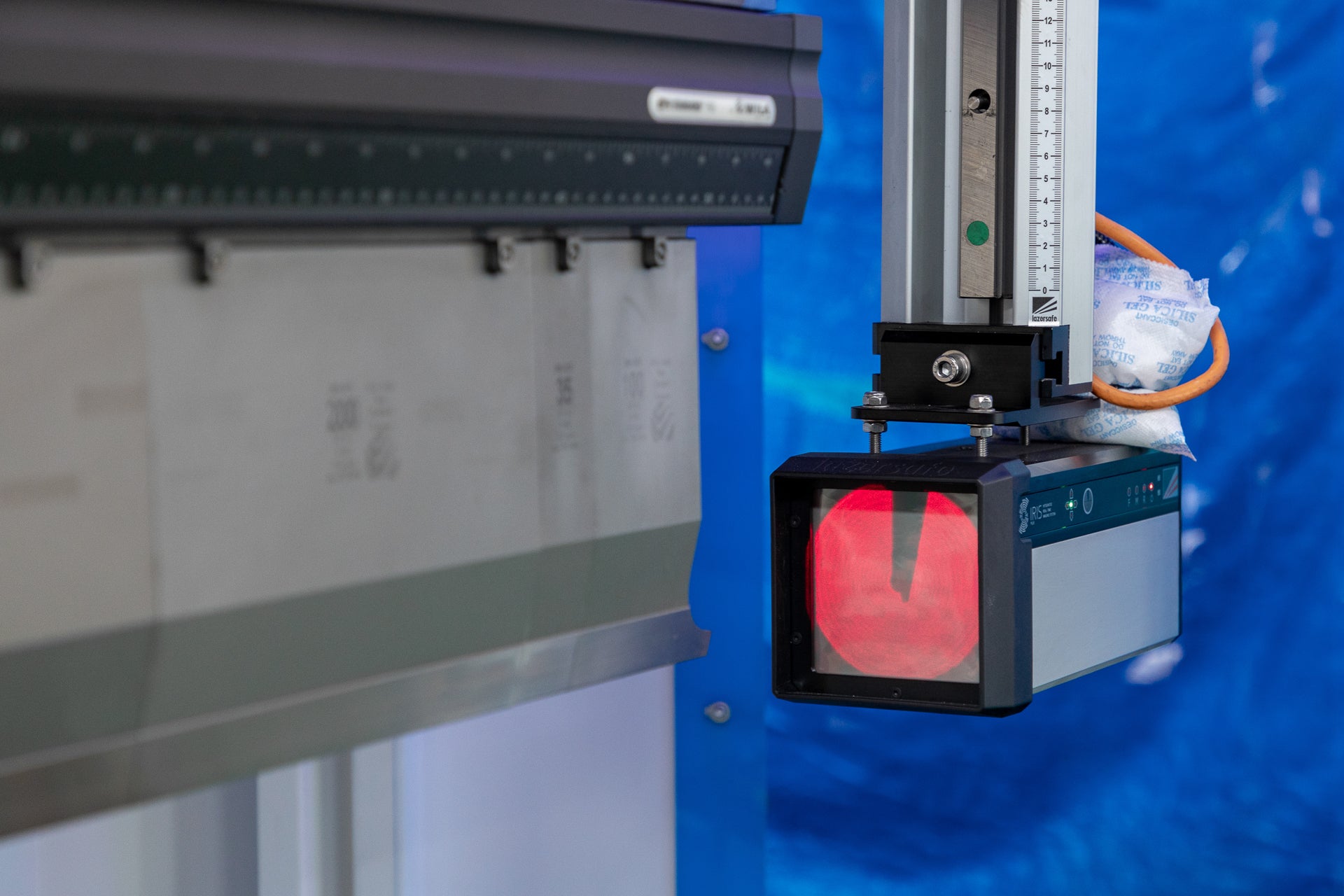

Safety Arrangements

Crowning System

Tooling Clamping System

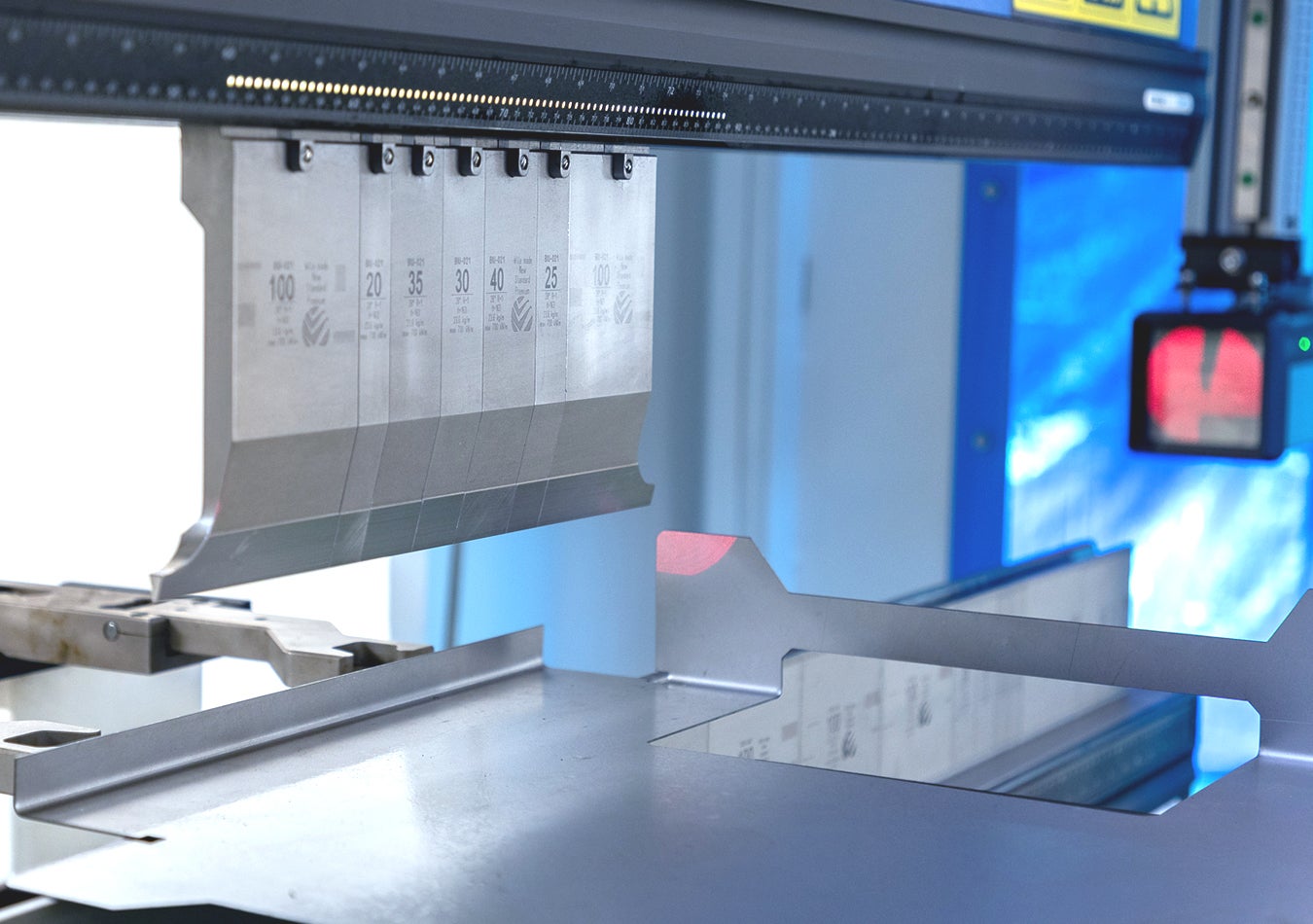

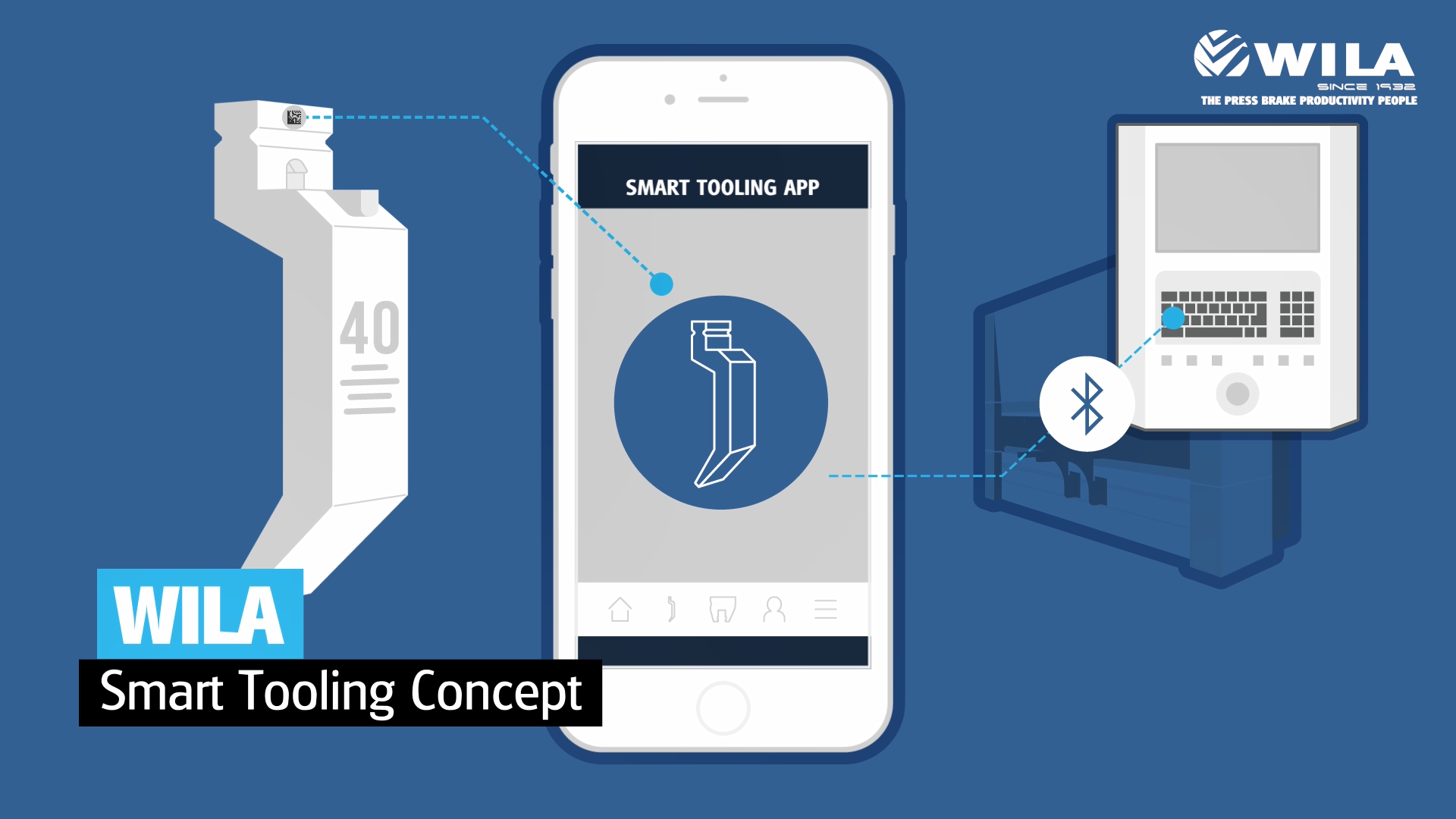

WILA Smart Tooling

Tooling and Tool Storage Solutions

Hybrid Servo ECO Function

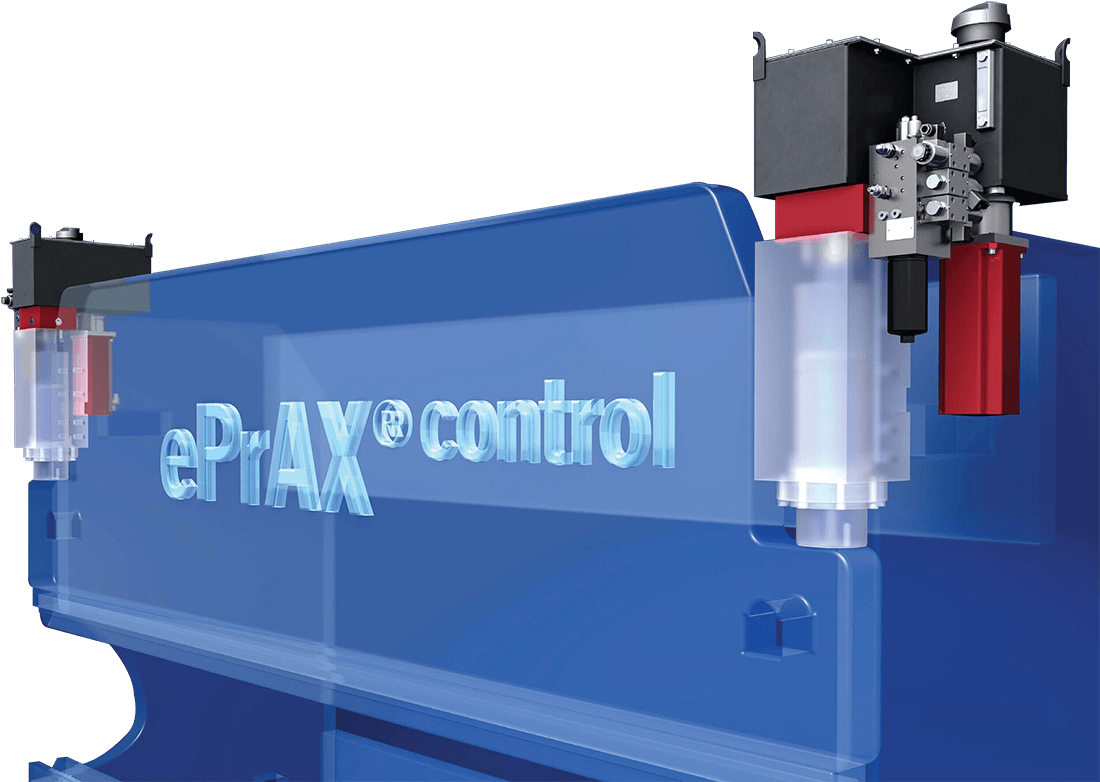

ePrAX® Hybrid Servo System

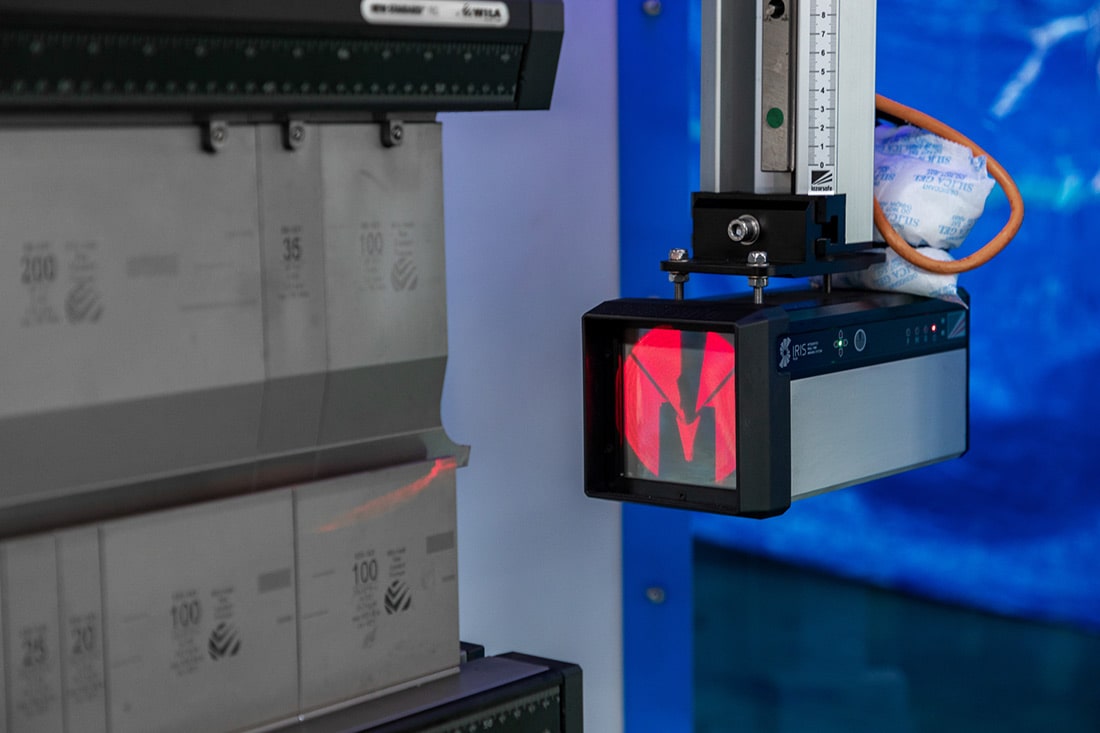

Bending Angle Measurement

Auxiliary Equipment

Sheet Support

Software

Bending Follower Supports

Industry 4.0 With Iot Productivity