ACCURL

Laser Welding Machine

ACCURL

SMART HLW Handheld Fiber Laser Welding Machine

Handheld Laser Welding technology for Fast High-Quality Welding

The Laser welding power up to 3000W is easily adjusted with intuitive controls to quickly dial in optimum weld settings for various materials and thicknesses. With up to 74 stored preset and user-defined parameters, novice welders can be trained and welding in a matter of hours.

ACCURL® handheld fiber laser welding machine has the best fiber laser beam for fast welding speed, high-quality weld seam and no consumables. In addition, we provide total solution for sheet metal working that customers want such as bending, cuting, deburring, and loading automation.

SMART HLW Handheld Fiber Laser Welding Machine

Includes Following Features And Configuration

Flexible

Reliable

Profitabie

User Friendly

Why Accurl Laser Welding?

Innovative Modular Design

- Our machines can also be combined with automation modules to create a complete system for the whole working process.

- Customized solutions at a reasonable price, from basic to high end machine.

Experience

- 33 years of experience and more than 12,000 installed machines.

- An expert R&D team committed to research the most competitive technology for our customers.

More Varied Solutions for Welding

- Sustainability and social responsibility are characteristics of modern companies and add to competitiveness.

- Comprehensive range of basic tools in stock and modified solutions according to customer needs.

ACCURL High Quality Equipment

- The critical parts of the Accurl laser machine are manufactured in Germany.

- We rely on our quality and therefore give our laser welding machine a 3-year warranty.

After-Sales Service

- Original ACCURL spare parts to guarantee full performance and prolonged durability.

- Wide range of consultation services on machine operation, programming and maintenance.

Laser Processing Tools

SMART HLW handheld laser welding and cleaning systems are fast, easy to learn and operate, and produce high quality, consistent results across a wide range of materials and thicknesses. Pre-weld and post-weld laser cleaning functionality optimizes weld quality while increasing productivity.changing the width of the beam.

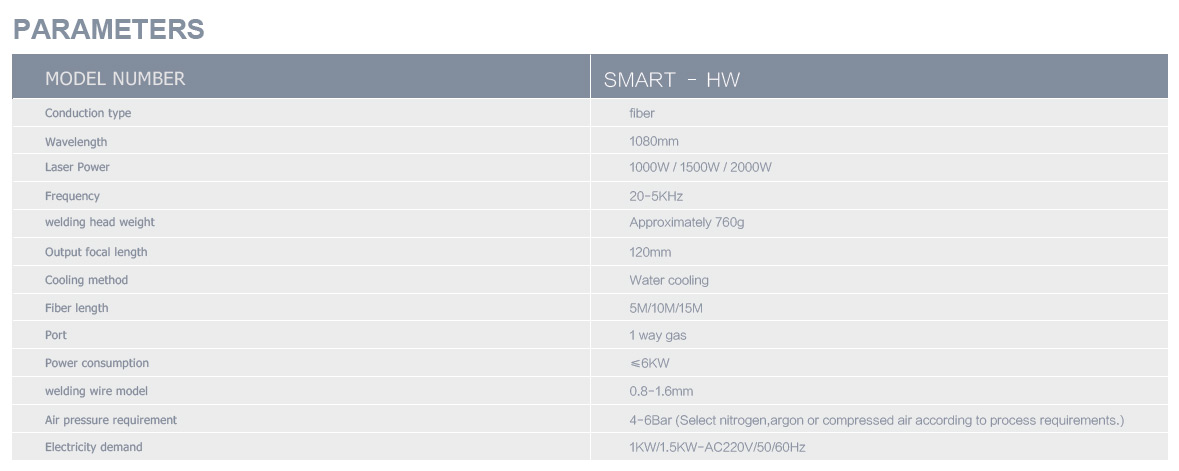

Simple Installation And Operation

The Clearly labeled rear connections make getting started fast and easy. Just plug in the power cord and gas connection, attach the workpiece clamp, and the system is ready to go.

Laser Welding Solutions

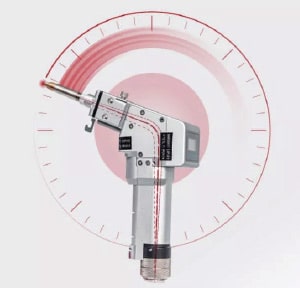

The ACCURL laser welding machine is equipped with a modern welding head with a moving beam and a swinging electrical system. It has a patented mechanism to drive the focusingens, allowing you to automatically change its position, thereby changing the width of the beam.

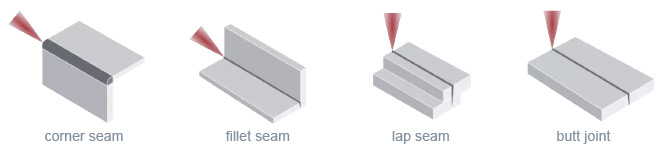

Versatile With All Welding Modes

It can be equipped with nozzles of various angles to meet the welding requirements of various products.

Operators can instantly switch between presets to accommodate many material thickness combinations.

Laser Welding Is Easy To Operate

Compared with traditional welding machines, 0 experienced operators can work on duty for one day of practice.

Built-in parameters ensure high-quality results.

Create highly aesthetic seams and weld parts with poor fit up.

Simple controls allow new welders to be trained within hours & experienced welders realize an immediate increase in productivity.

ACCURL Easywire Automatic Wire Feeder

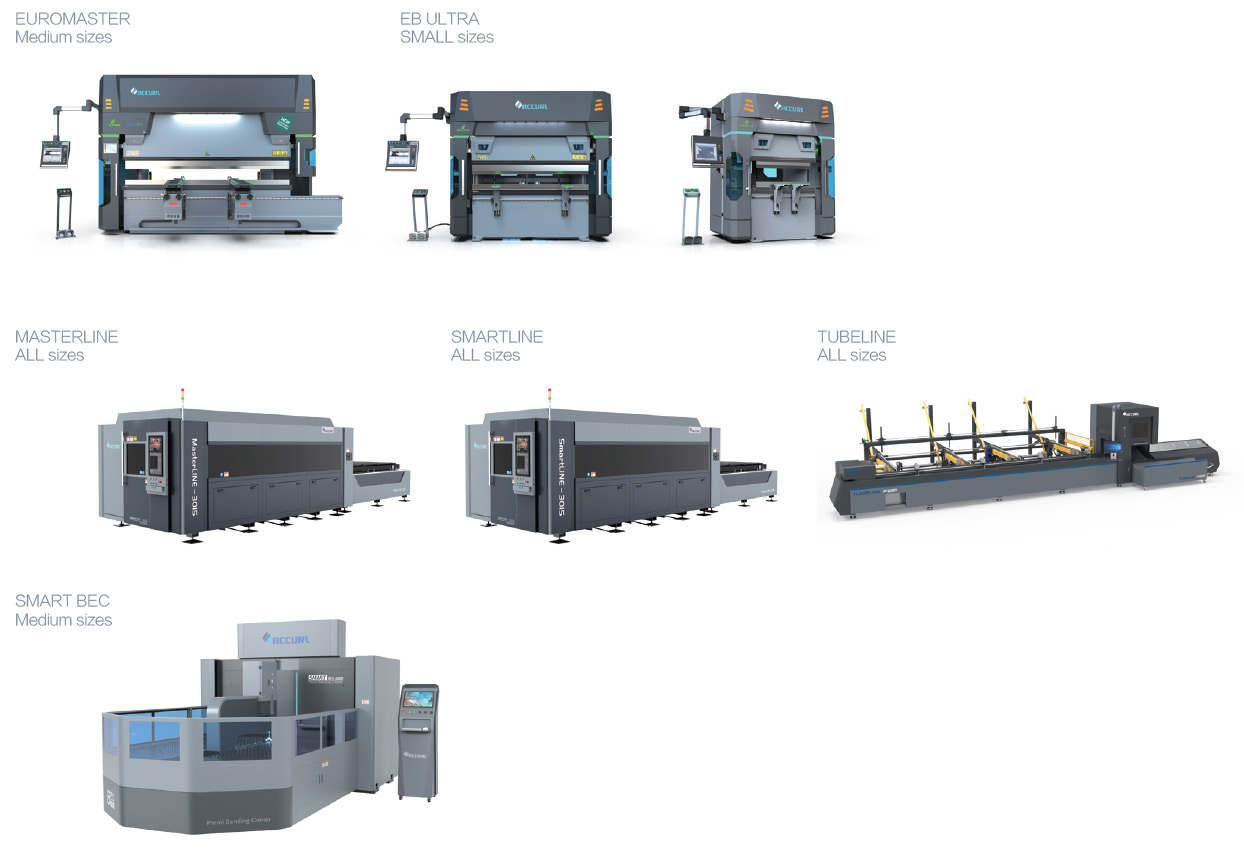

ACCURL Laser Welding Product Range