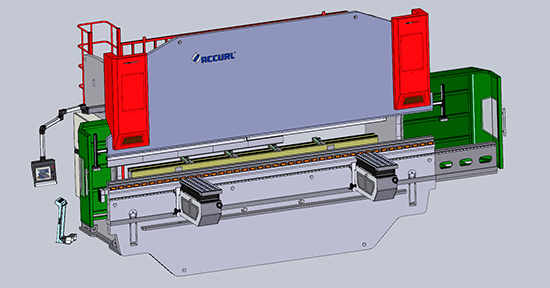

R&D And Processes

Mechanical Engineering Design

ACCURL have vast experience with R&D and designing components to very tight tolerances with SOLIDWORKS 3D CAD modelling techniques, and ACCURL Engineers are competent in designing with first principle calculations for the CNC press brake and laser cutting machine.

The design and analysis experiences of computer aided engineering (CAE) used in the heavy industry is novel for conventional company before prepare going to execute the fourth industrial revolution.

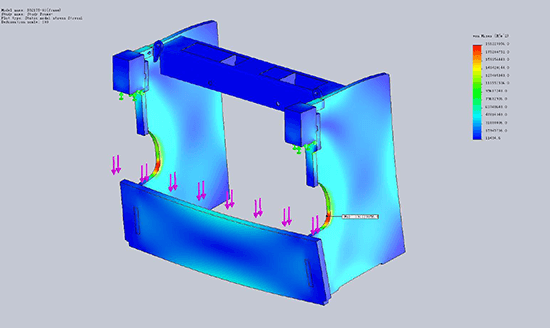

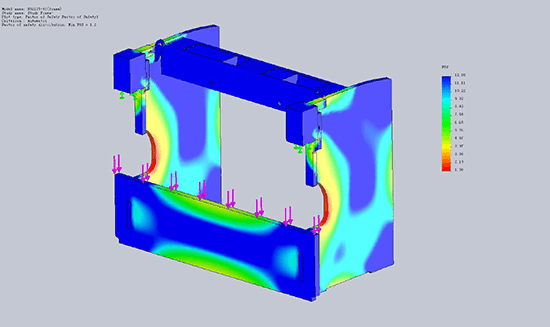

FEA & Stress Analysis

The CAE software SOLIDWORKS used as the method to analyze the linear static construction, stress and deformation for press brake and laser cutting machine frames. So for complicated structures, highly complex loading’s, transient modelling and combinations of the above, FEA makes sense.

Heat Treatment Processes

ACCURL press brake and laser cutting machine steel frames undergo annealing at over 600⁰ to relieve stress and they are built to last years of heavy use without distortion.