ACCURL

BEC SMART-Series

PANEL BENDER

ACCURL

One Step Forward in Bending

MODEL: BEC SMART-1400~2500

Max. Bending Length: 1400 ~ 2500mm

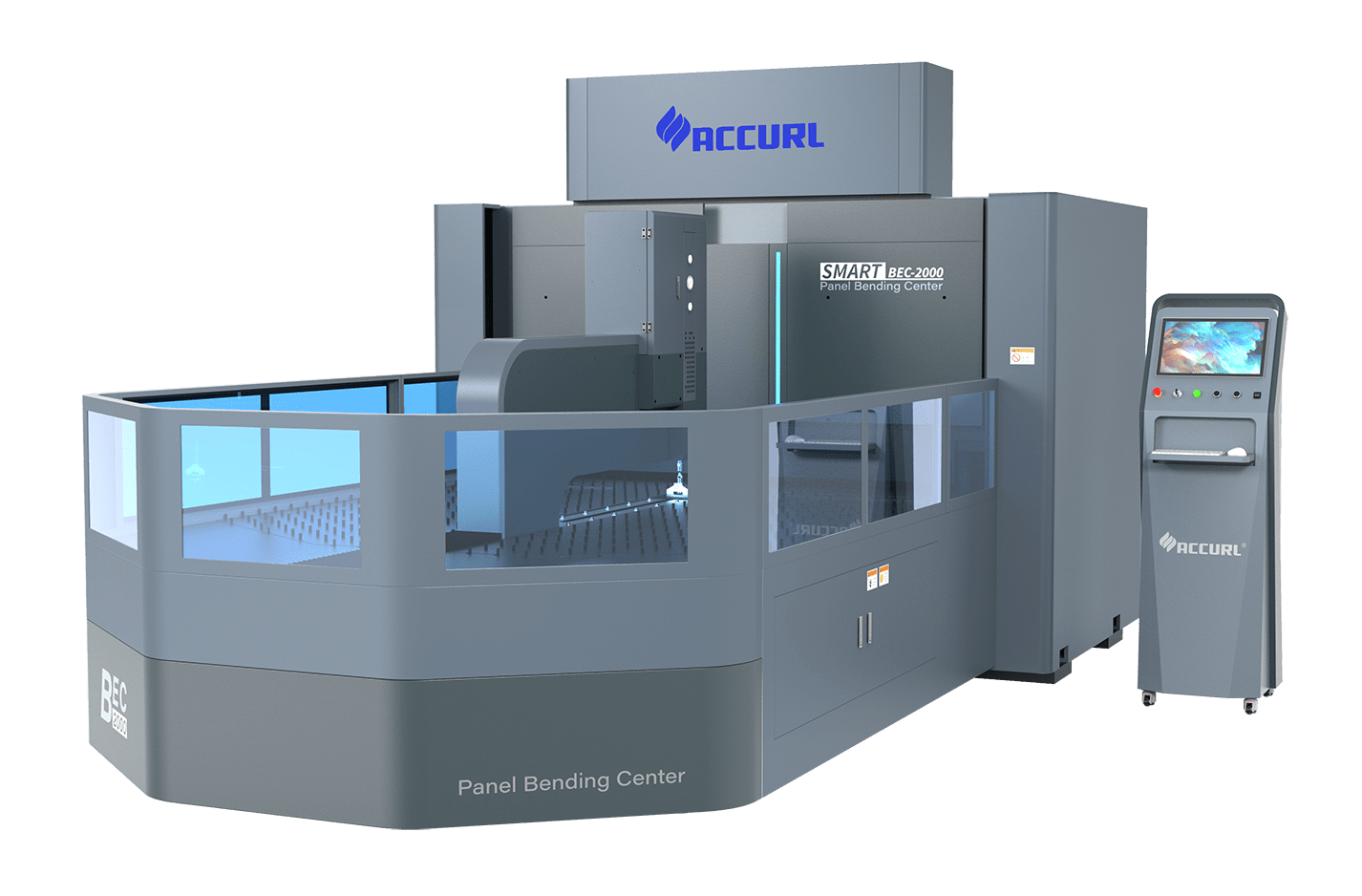

ACCURL China has launched its new sheet metal CNC panel bender, designed to satisfy the most demanding market needs. With an innovative design, this is the result of more than 35 years of ACCURL’s own know-how in the field of bending as Panel Bender VS Press Brake.

BEC SMART Series

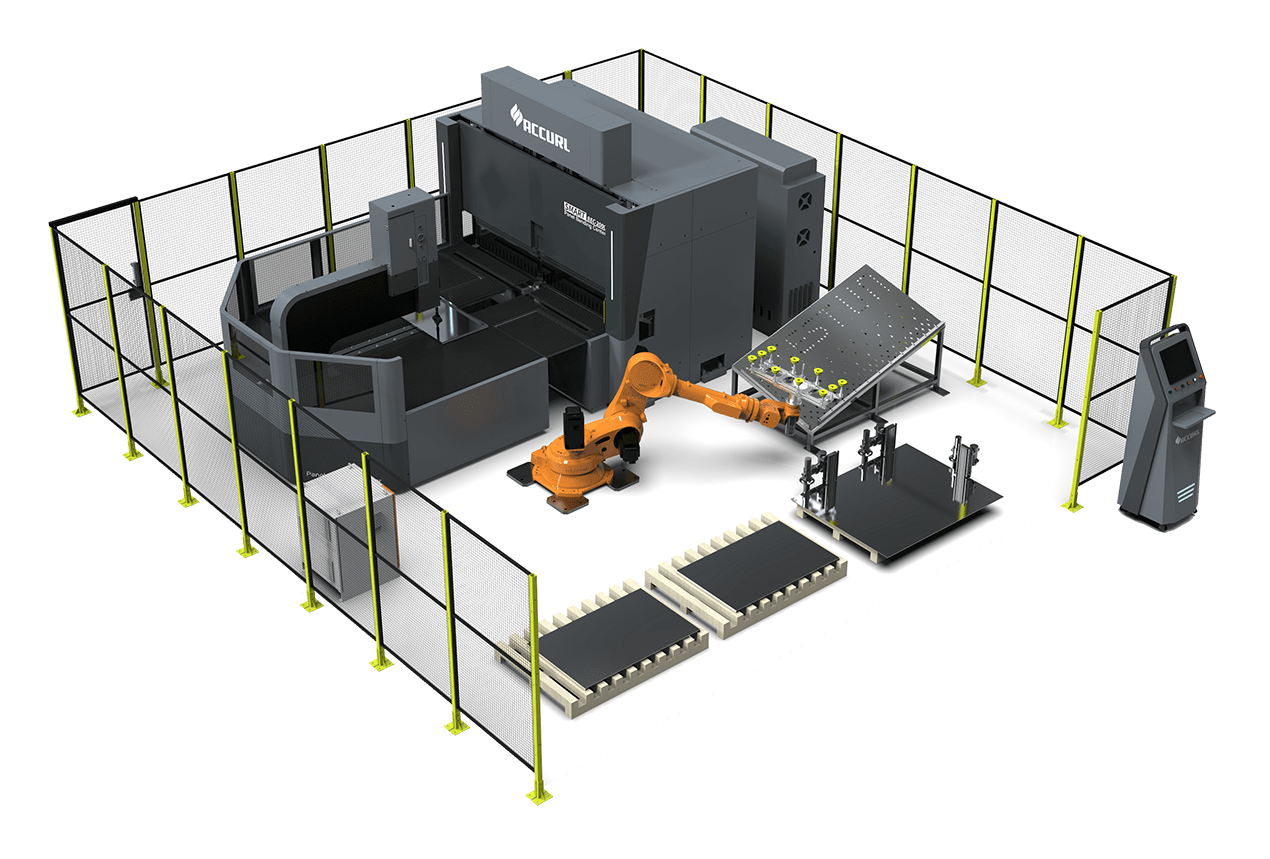

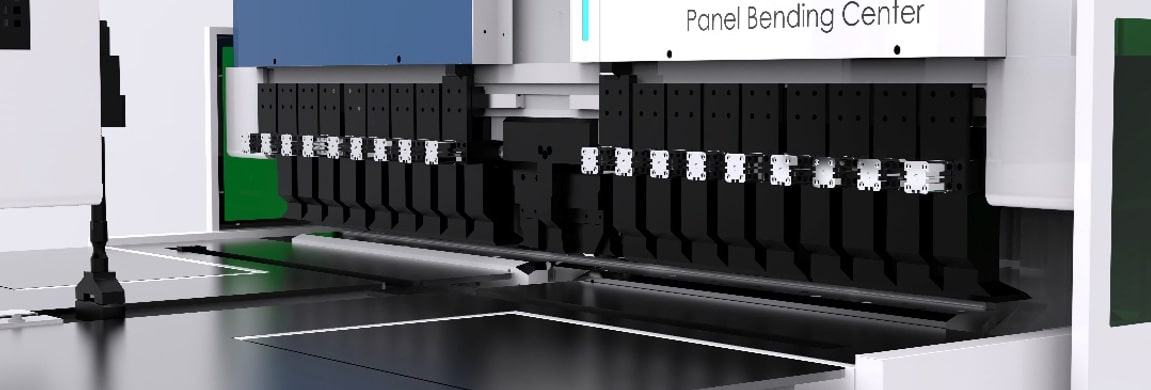

The BEC Smart CNC panel bending machine cell is a revolutionary bending solution thanks to the “safety integrated” concept that allows the operator to focus only on value-added operations, aided by visual devices and sound signals. Its compact layout and combined loading and unloading sequence guarantee high productivity, constituting a very important investment for anyone looking for a flexible and semi-automatic panel bender.

ACCURL BEC Smart automatic panel bender has been designed with a modular concept, so that it may incorporate a large range of accessories and offer fully automated solutions

Perfectly equipped for sensitive bending Energy efficient solutions

The Panel bender with its easy to use control units, rigid body frame, perfect design, high efficiency, multiple tool usage solutions for Automatic bending,

- Compact Solution

- 100% Full Servo-Electric System

- Electrical Energy Savings

- Regular Production Independent From the Operator

Industries that use BEC SMART

- Office Furniture

- Heating & Ventilation

- Air Conditioning

- Domestic Appliances

- Shelving

- Lighting Fixtures

- Telecommunications

- Electronics

- Subcontracting Enclosures

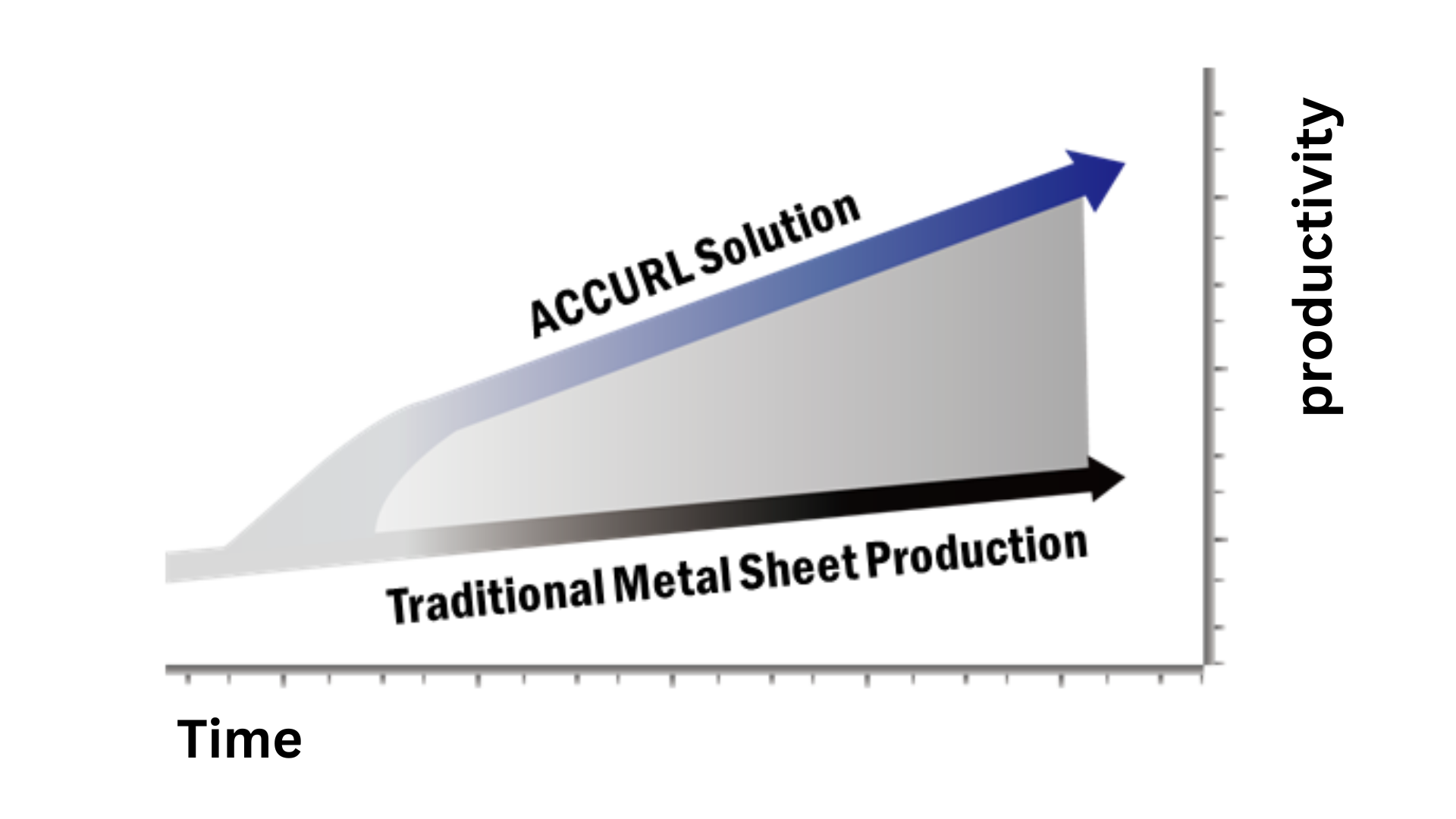

BEC SMART panel bender increases productivity much more than traditional press bending method.

Unlimited bending

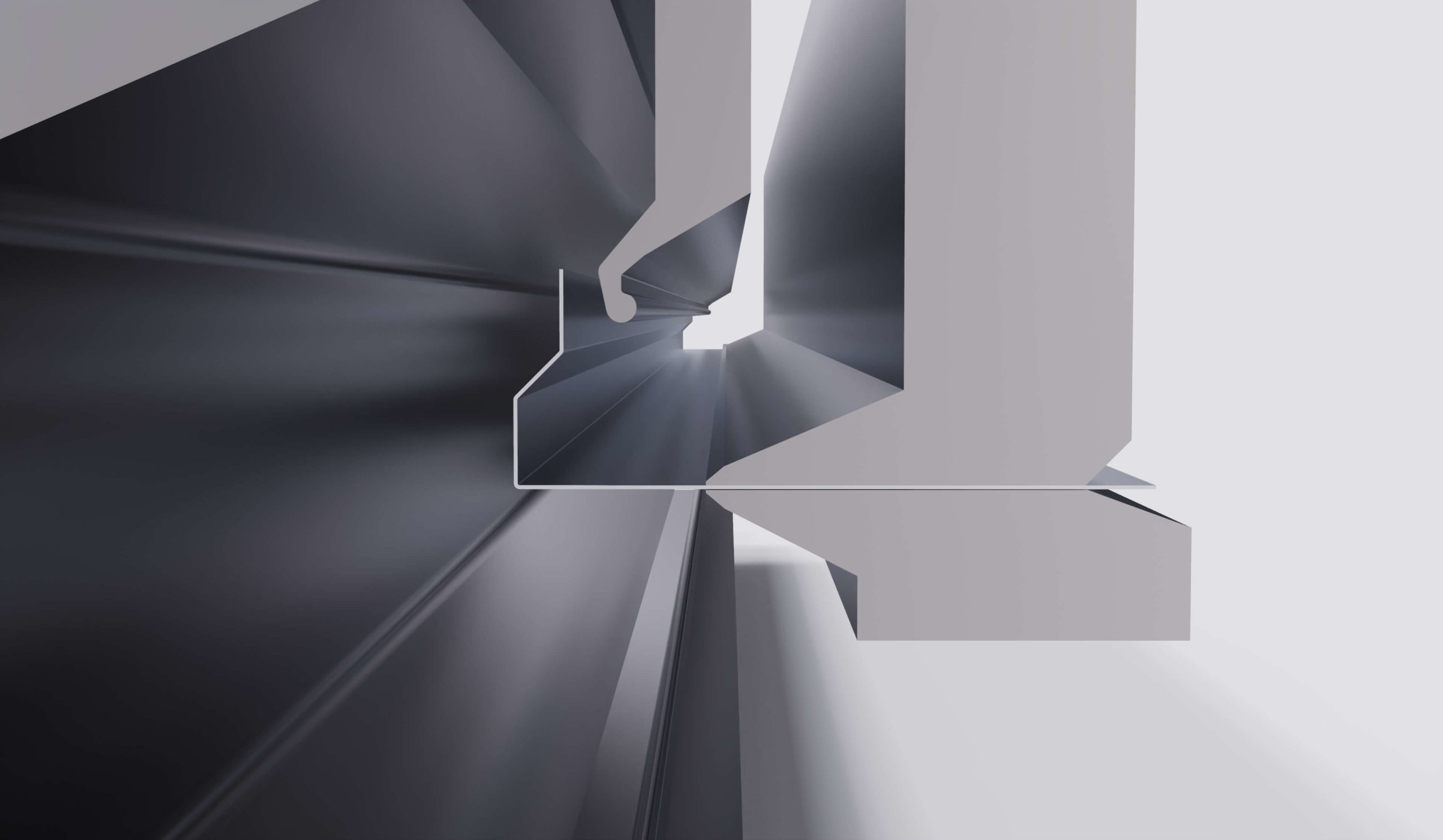

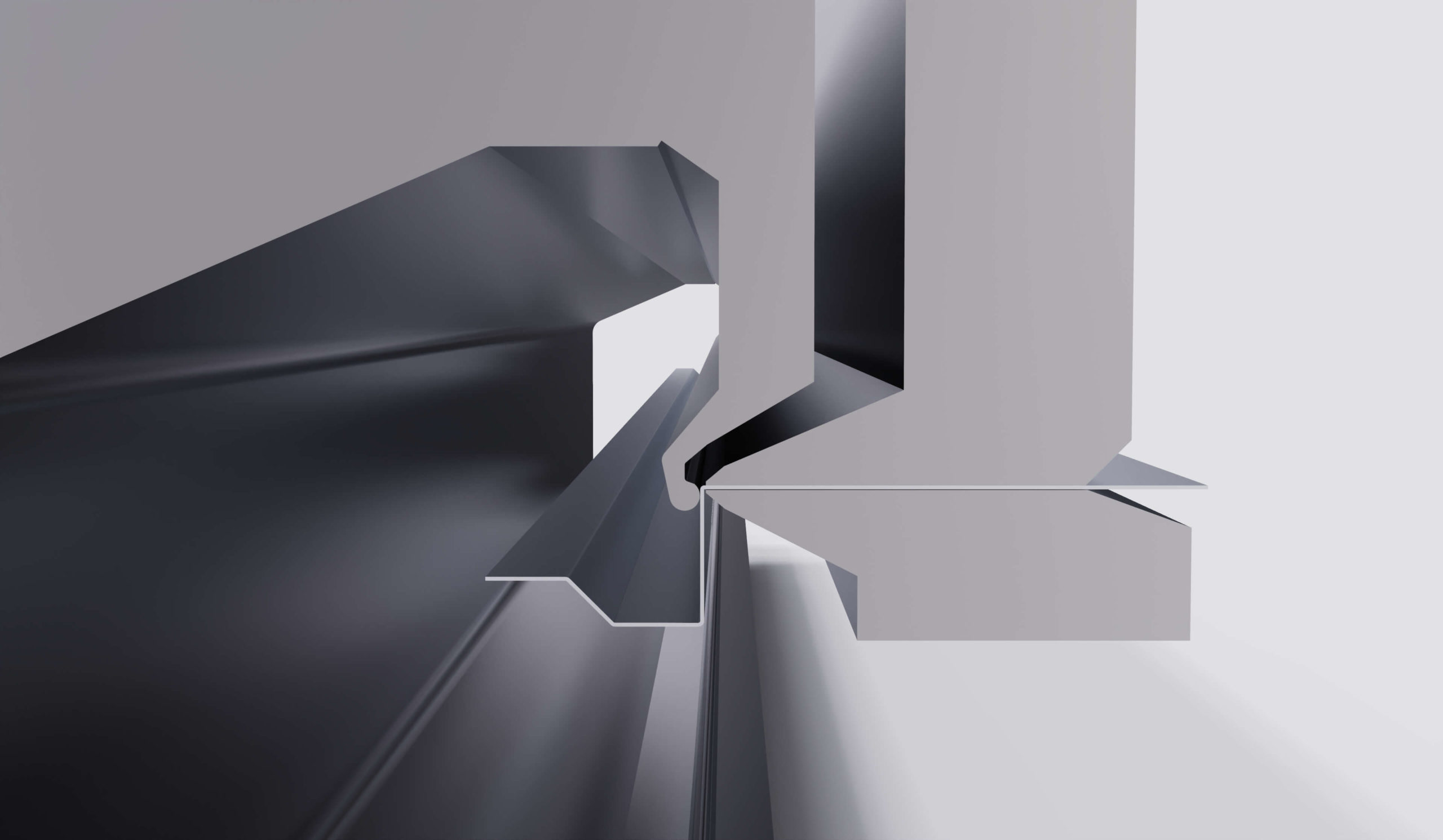

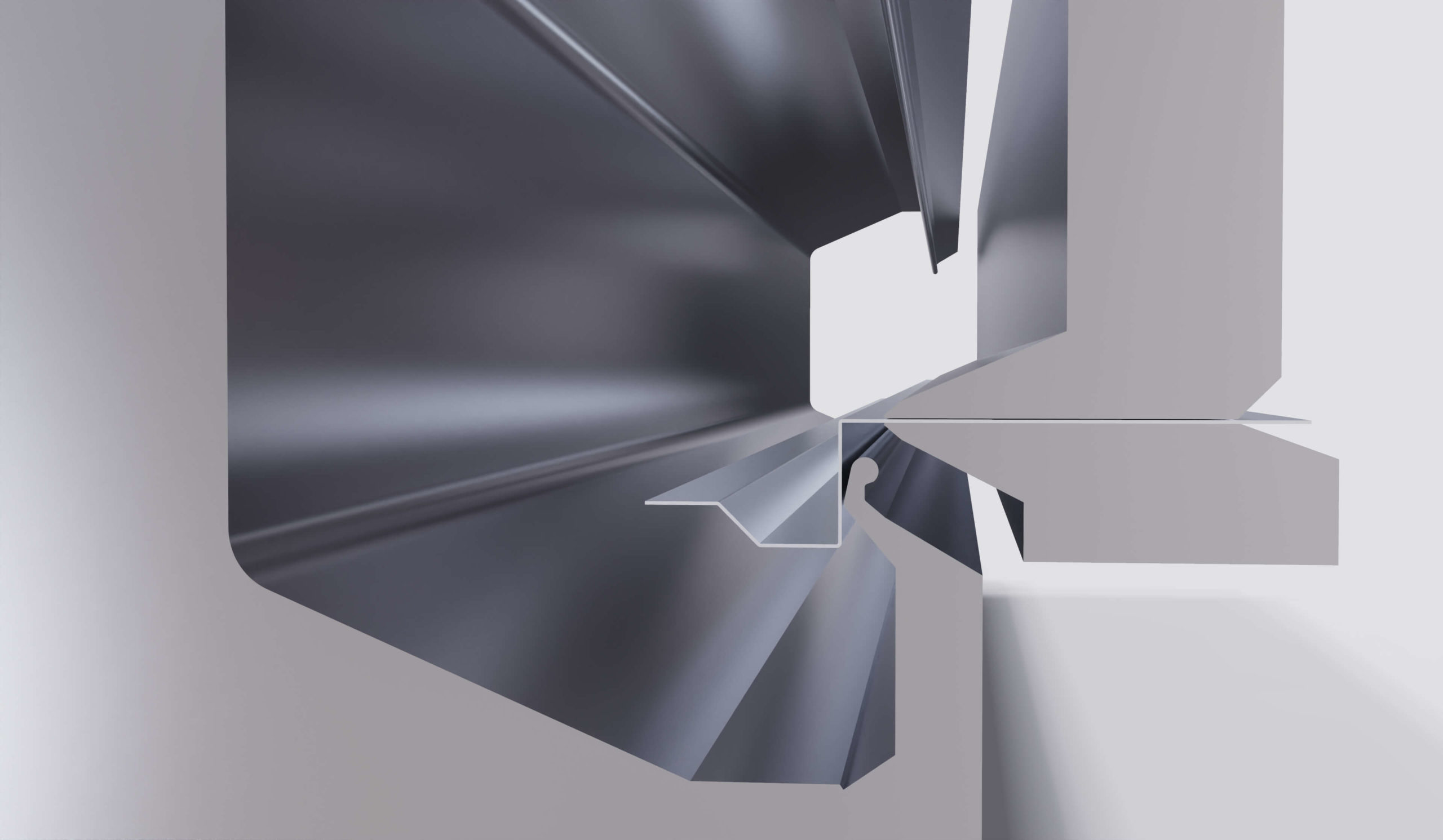

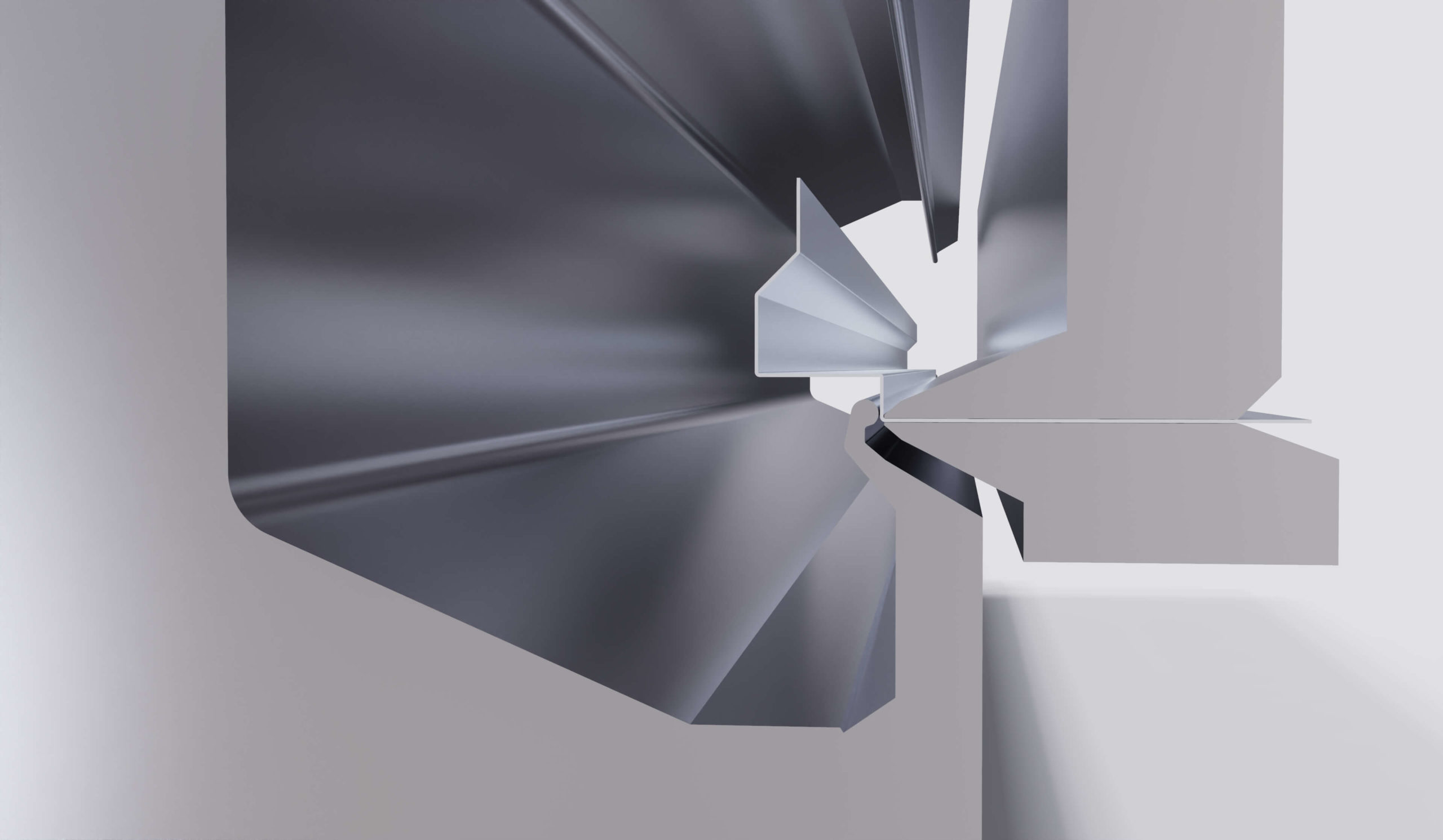

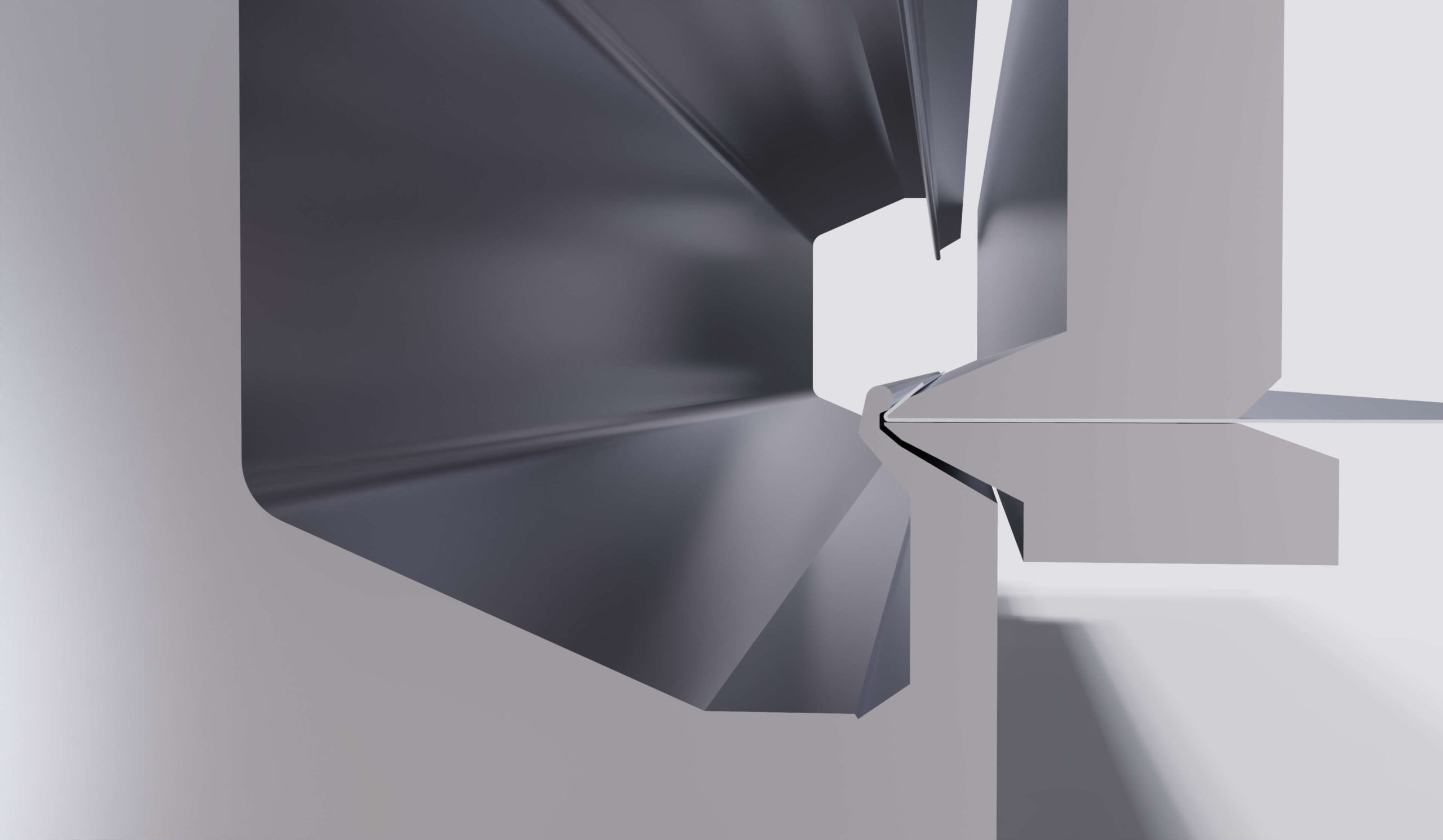

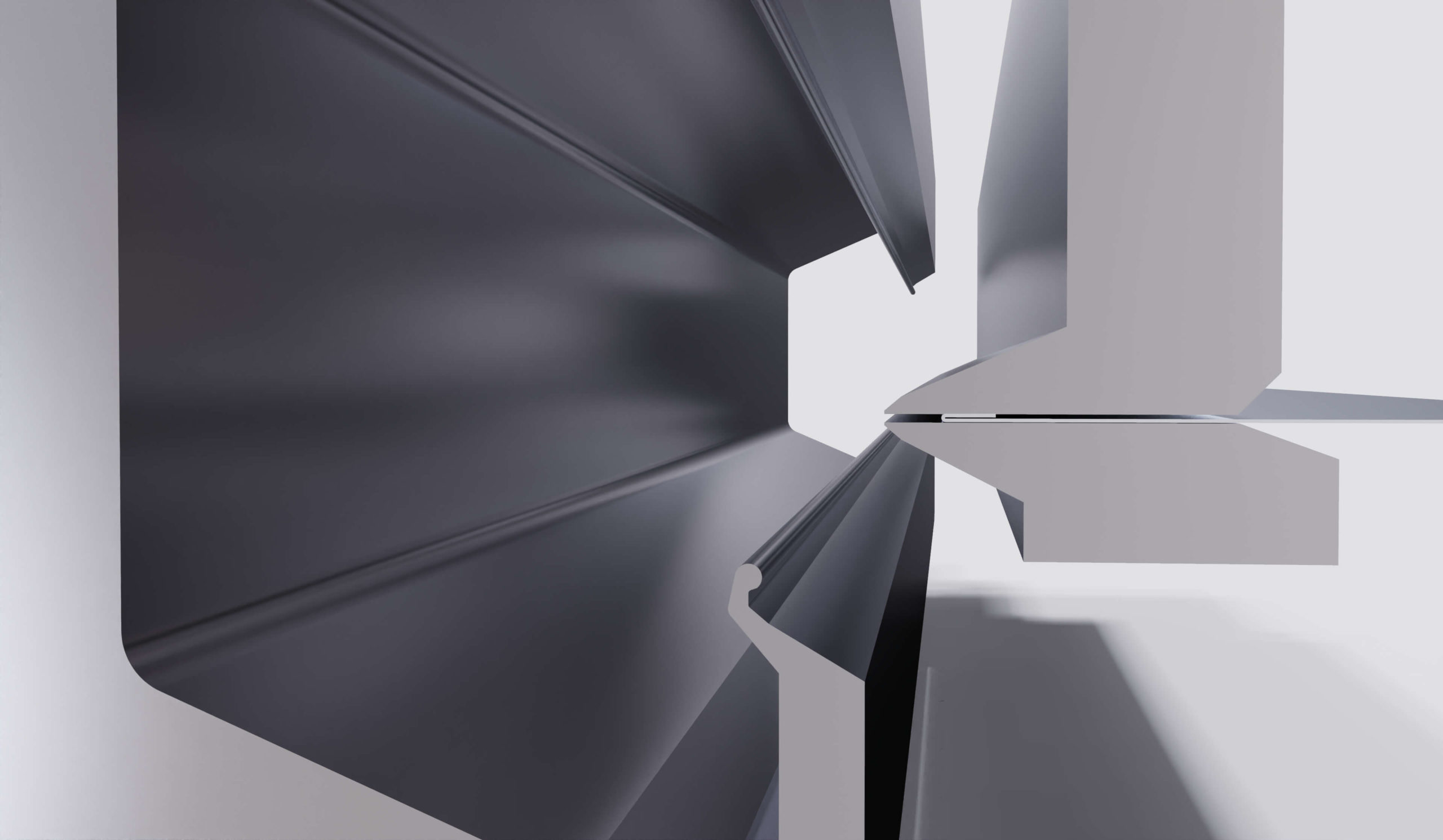

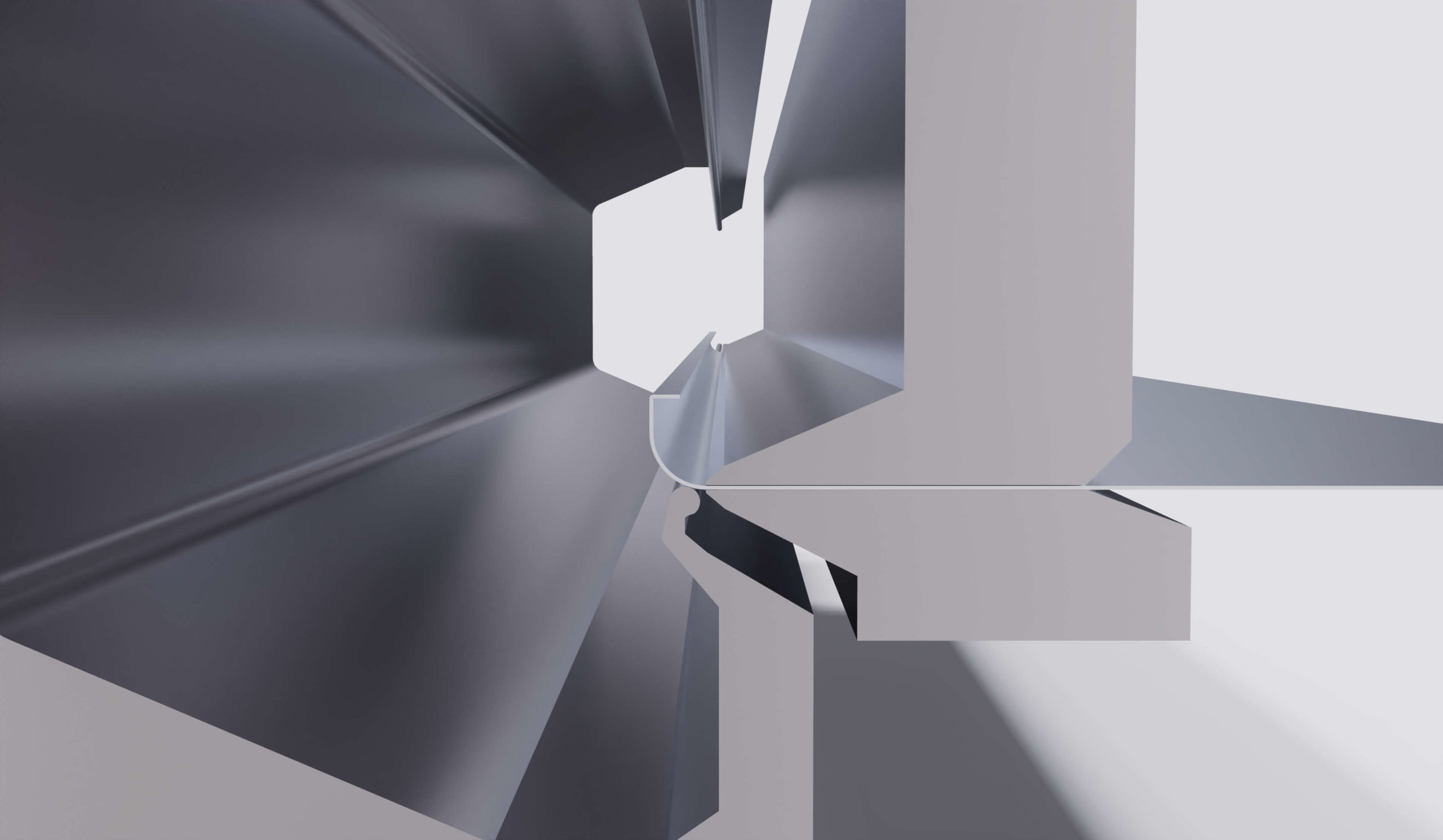

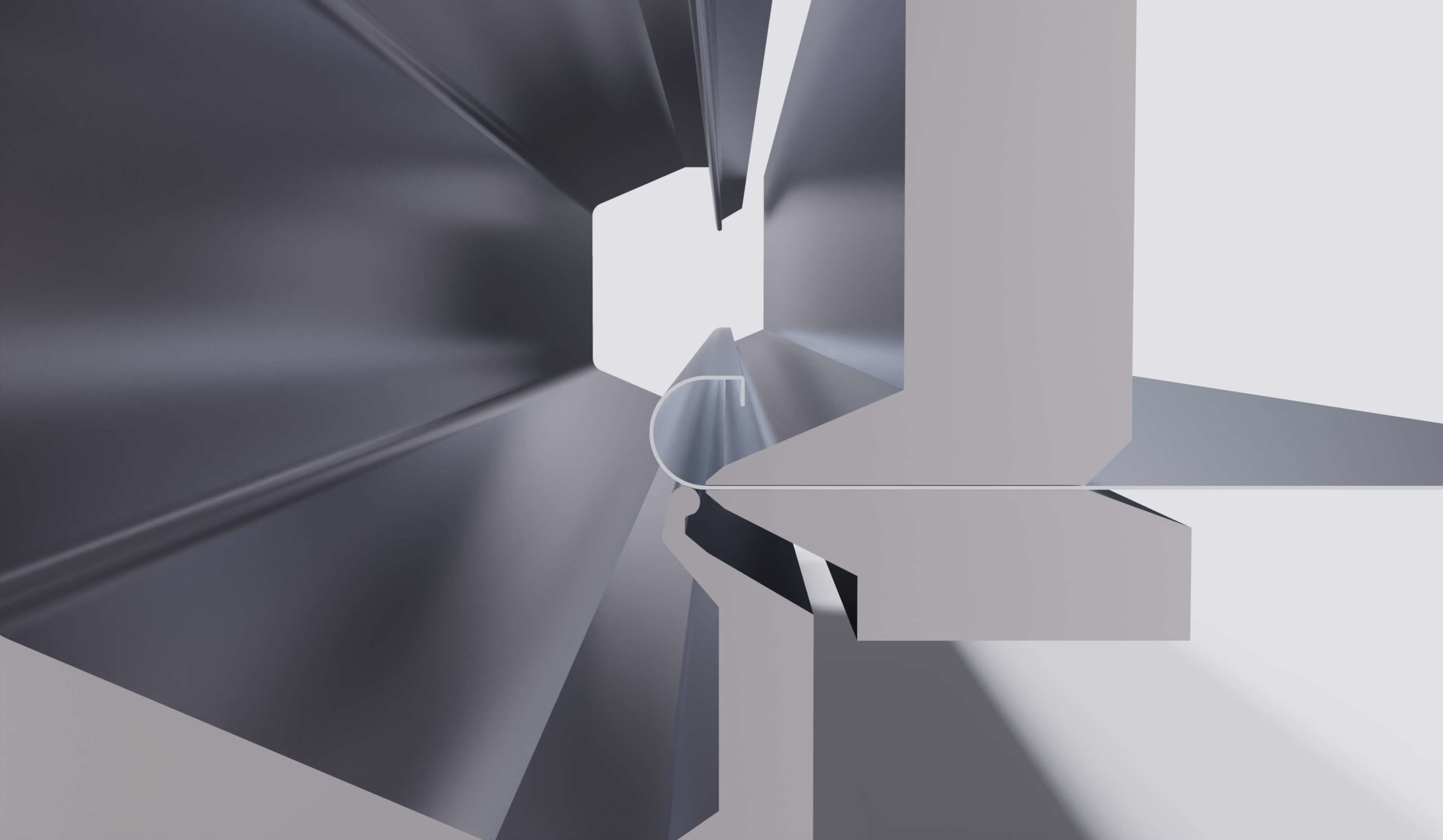

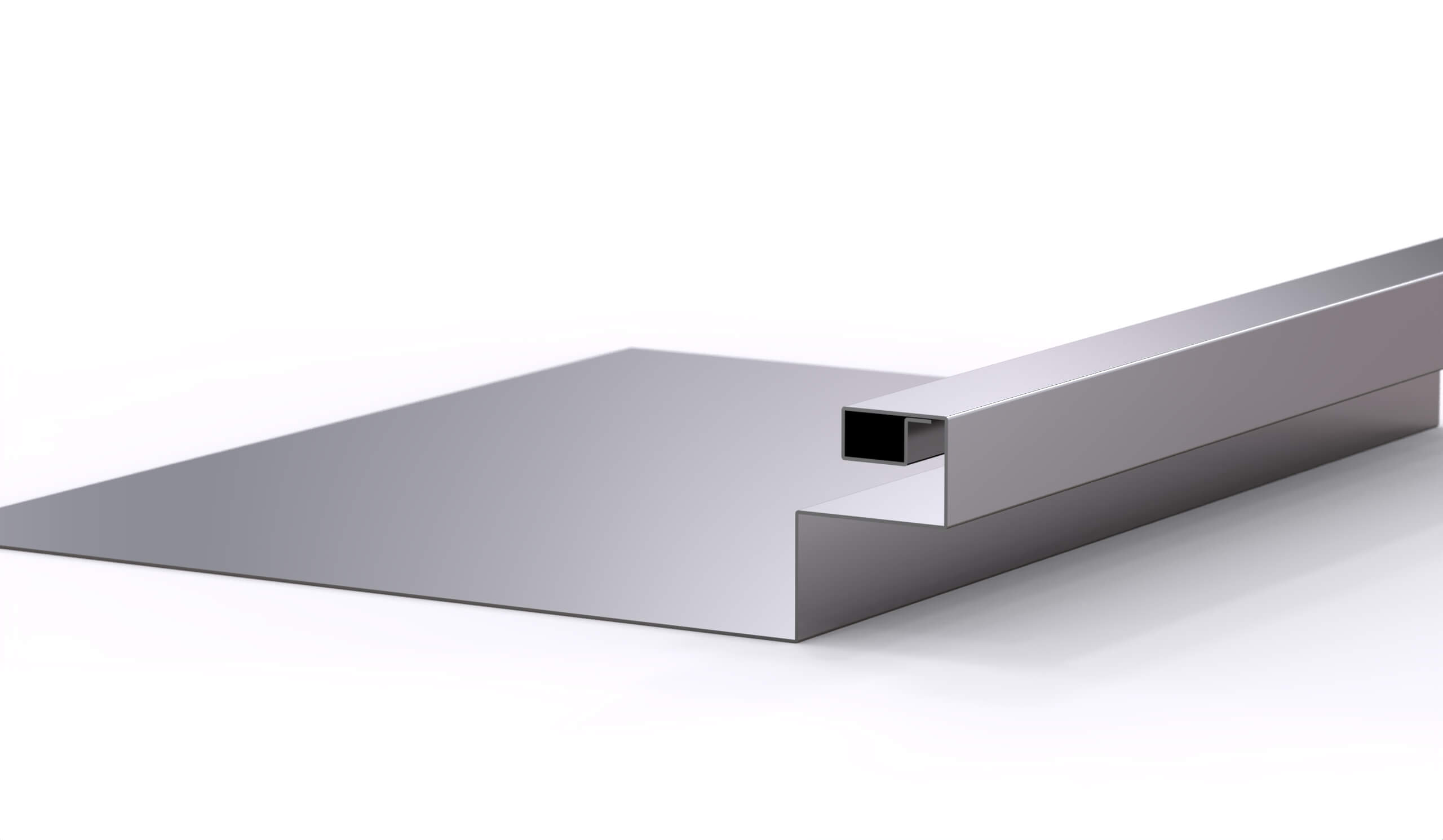

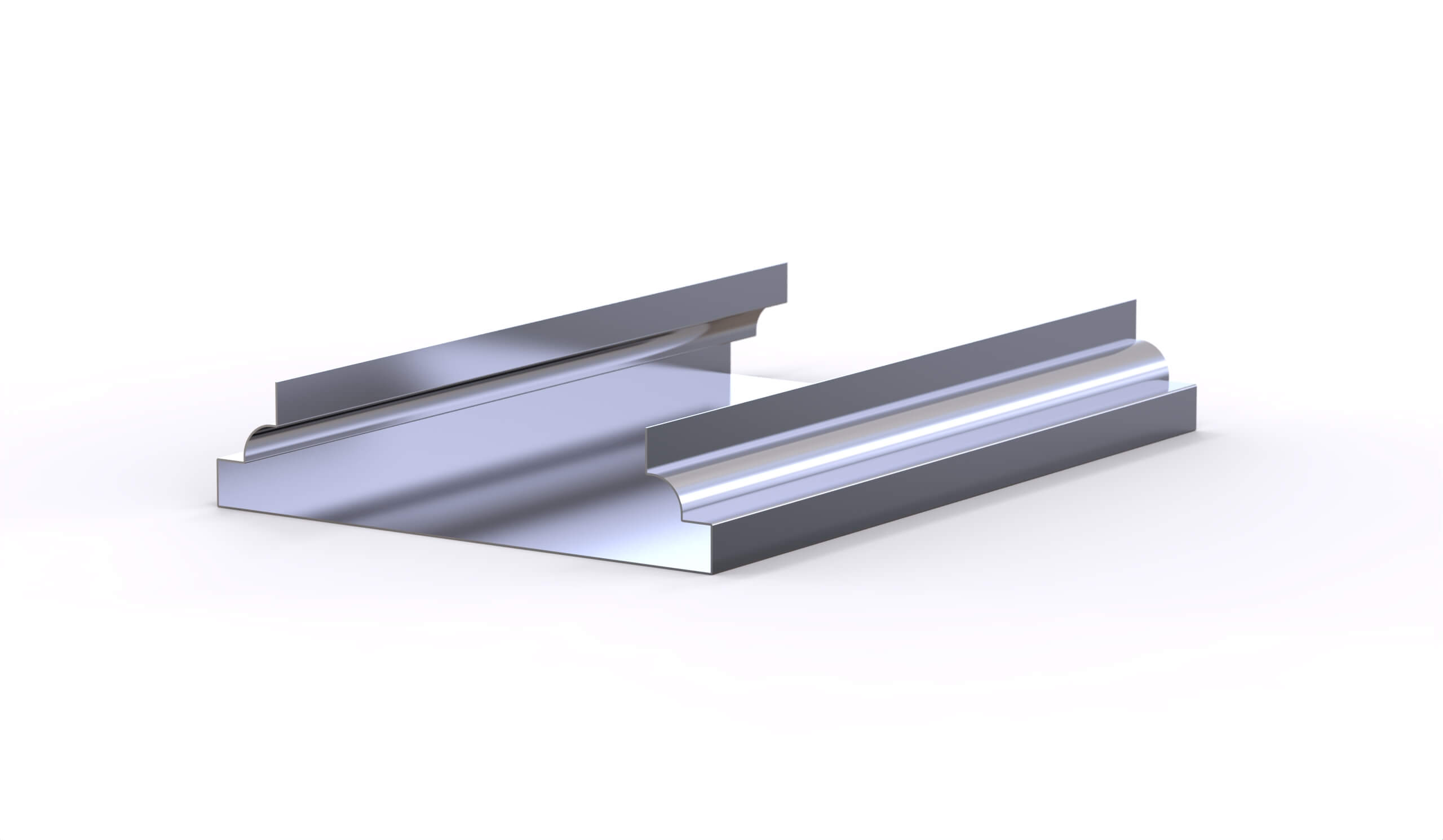

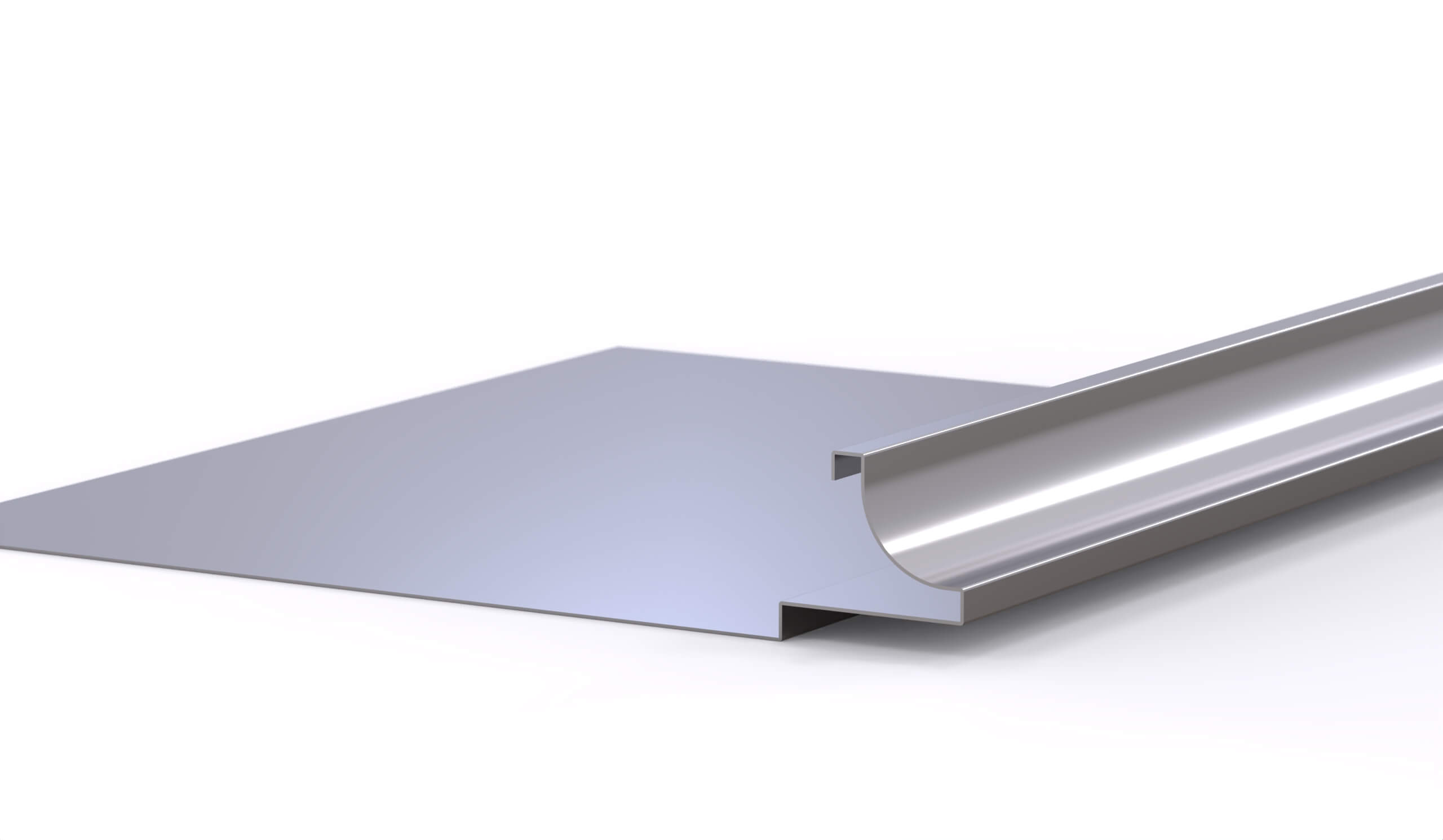

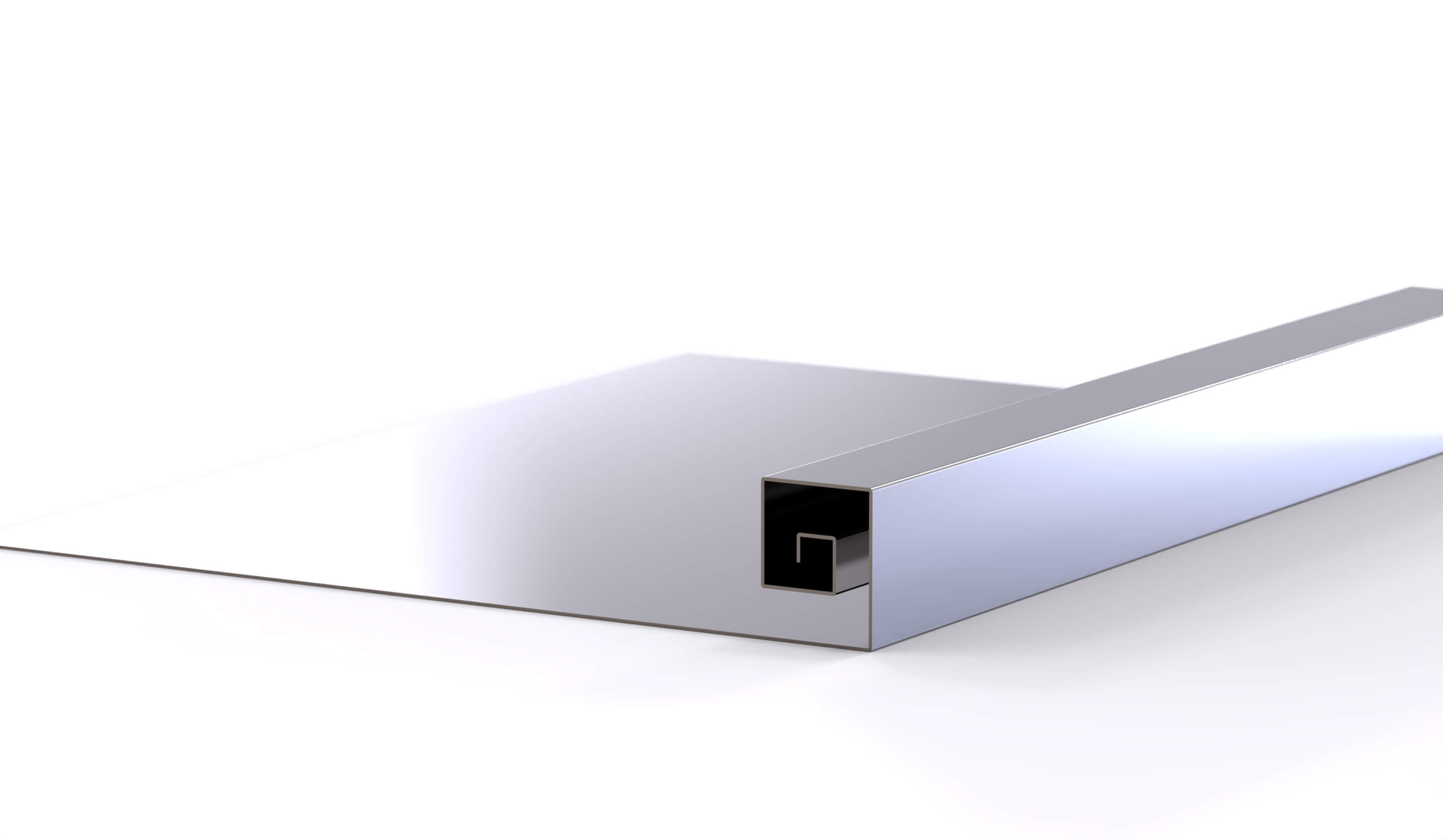

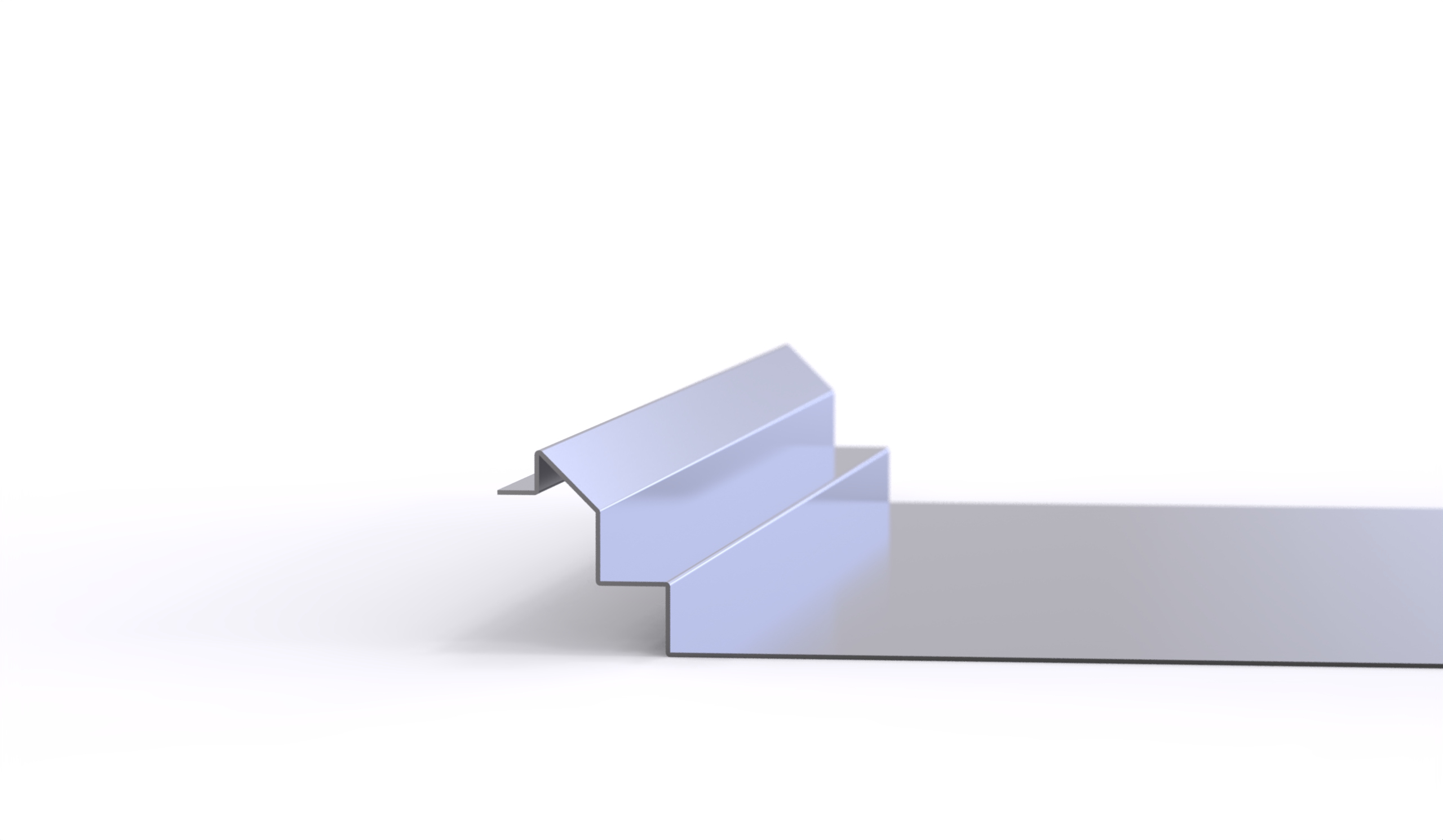

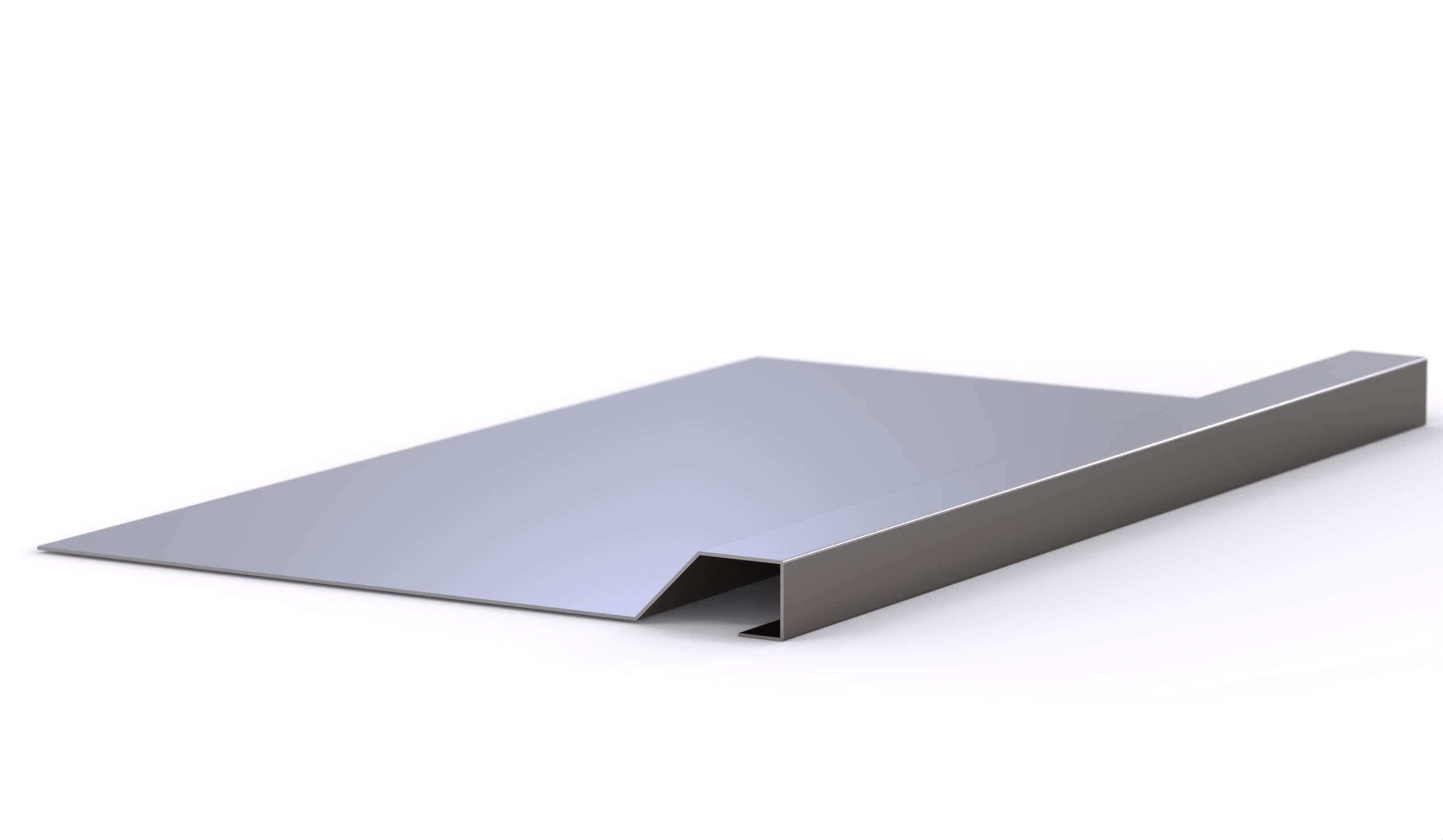

Its universal tool concept, along with the possibility of changing customized shaped tools, make the BEC SMART machine the all-in-one highly versatile solution, allowing the manufacturing of a wide range of bending applications. The universal tooling can make both UP and DOWN bending process, without switching surface of the sheet.

It can also make HEM bending and big ARC bending automatically. Achieving this type of bendings brings ADDED VALUE to the final part.

BEC SMART Series panel bender is the new generation automated bending solutions, a benchmark that indicates the upgrading to automation of sheet metal fabricating industry. It can obviously reduce the labor cost and at the same time it can realize 300% higher efficiency comparing to traditional press brake up to 0.3s per bending. Full electro servo transmission plus closed-loop BUS control makes the accuracy far better.

Features

- Fully automatic bending, high efficiency, energy saving and environmental protection.

- Bus control, which can be directly connected to the IOT(Internet of Things) for remote control and monitoring.

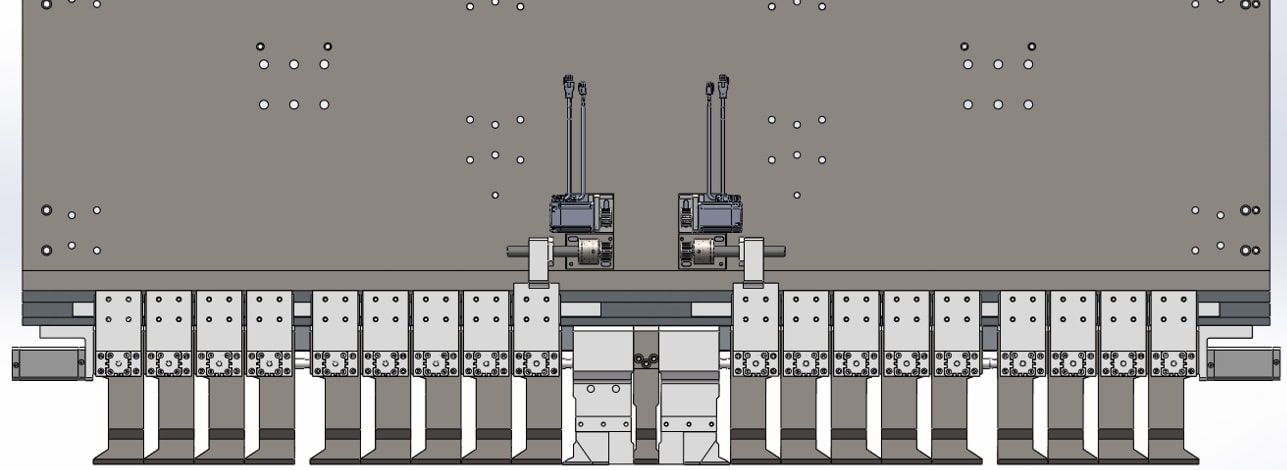

- Special high-load screw and guide rail structure, high load-bearing capacity, high positioning accuracy and long life.

- Fully automatic lubrication system, maintenance-free.

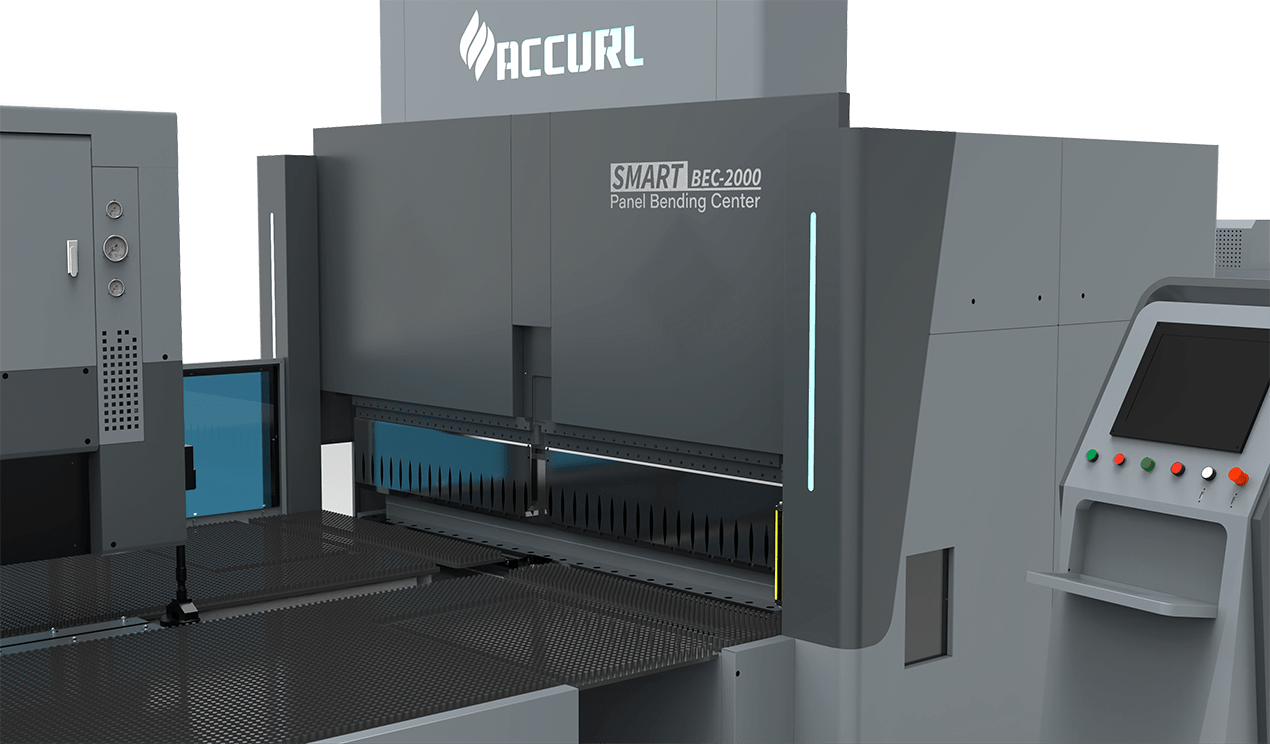

- C-arm feeding structure design, double servo rotation up and down, automatic downward press structure, rapid downward press, adjustable pressure, high rotation positioning accuracy.

Operating mode: simple and quick

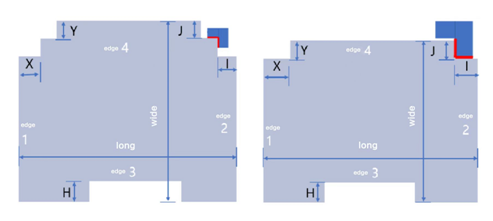

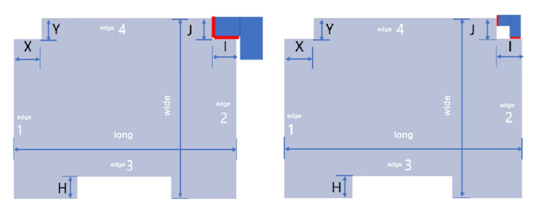

Bending on each side of the sheet is achieved thanks to the controlled interpolated movements of the blades.

Finish complex parts in one set up.

Universal Tooling

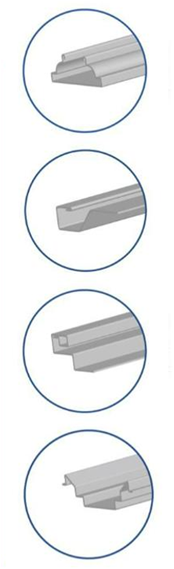

The Flexible Panel Bender bends the sheet metal with one universal tooling, able to bend various complex shapes.

It can fold 90 angle, non 90 angle, circular ARC, positive/negative and other complex shapes, now days flexible panel bender become more and more popular in the metal forming field of different industries and different workpieces.

Here listed some typical applications:

Main Features

PLATE WELDING FRAME

The servo motor controls the movement of the positioning L-block, which is fast and accurate.

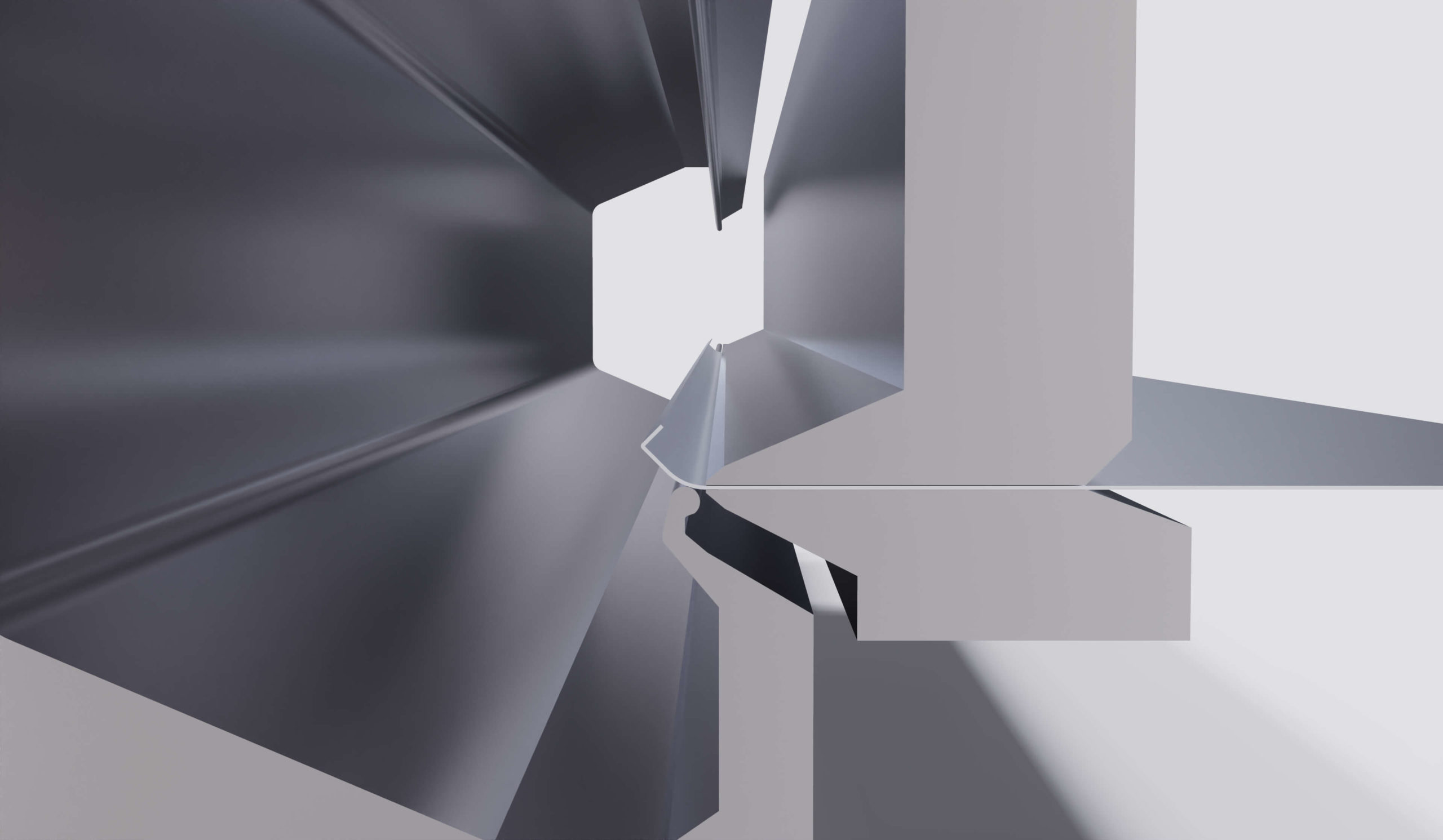

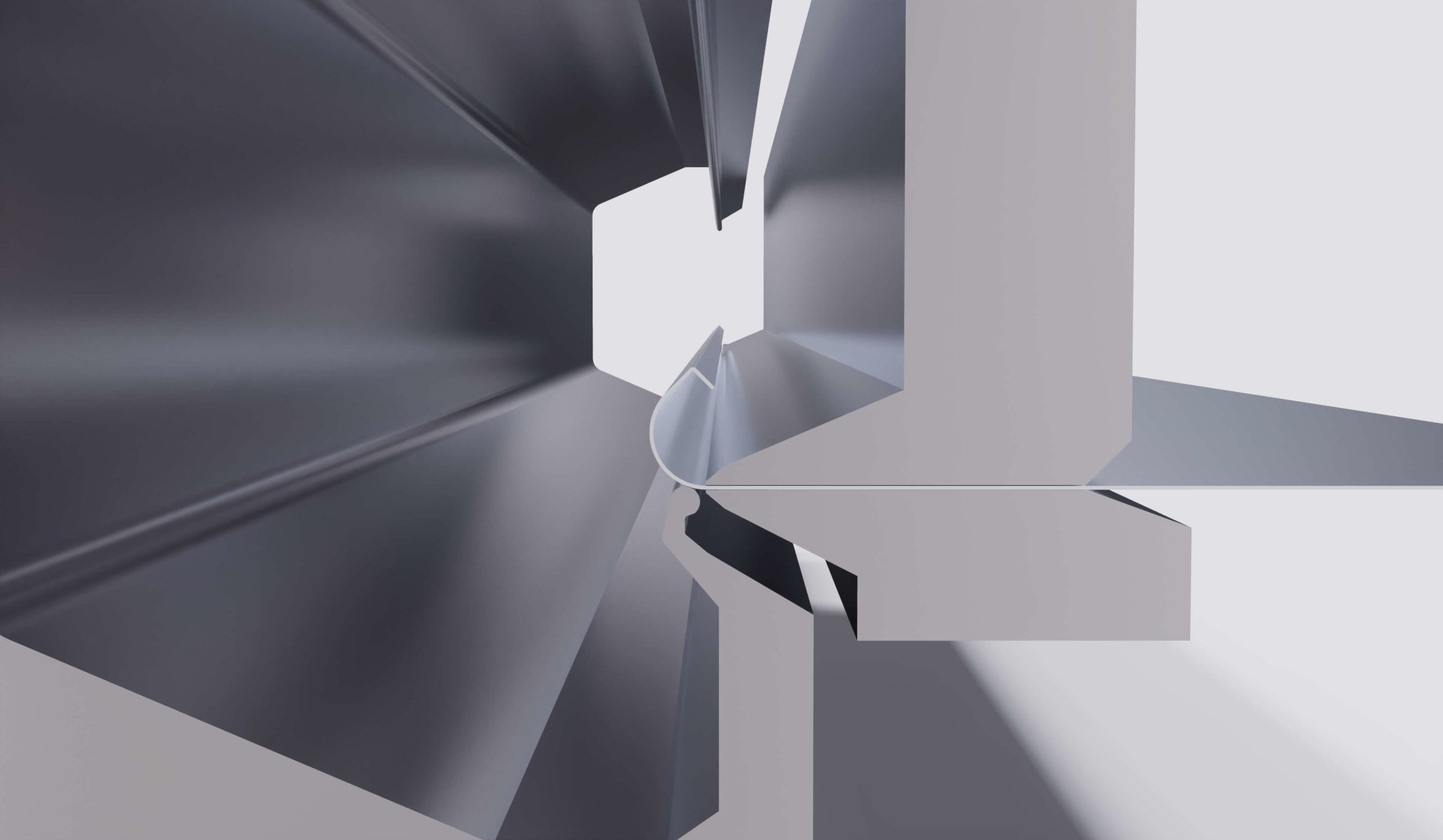

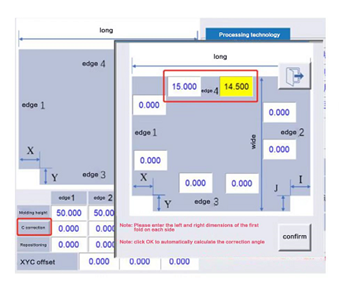

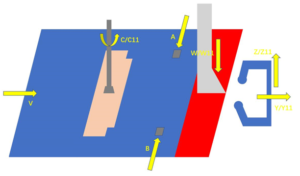

FEATURE-AUTOMATIC CORRECTION OF ROTATION ANGLE

The arc bending process requires repeated bending of the plate. If the rotation angle is not in place, the bending error will accumulate each time, resulting in the folded workpiece is not an arc, but a cone.

The automatic correction function can automatically adjust the C/C11 axis to compensate for sheet rotation errors.

CNC AXES-11 AXES

- A/B axes: Positioning axes

- V axis: Feeding axis

- C/C11 axes: Rotation axes

- W/W11 axes: Pressing axes

- Z/Z11 axes: Tooling up&down motion axes

- Y/Y11axes : Tooling forward&dbackward motion axes

The frame is tempered, annealed and aged twice to ensure the long-term running accuracy, stability and high rigidity of the machine.

Automatic Tooling Change Section System

The system uses universal bending tools which automatically adapt in-cycle to the panel geometry, without machine down times or manual retooling, allowing batch-one or kit productions.

Flexible Automation

Quickly and fully automatically, this moves, handles, grips and rotates the sheet metal throughout the whole machining cycle. It requires no manual interventions during the cycle. The operator positions the sheet metal on the worktable and collects the product after bending, performing only the loading and unloading operations.

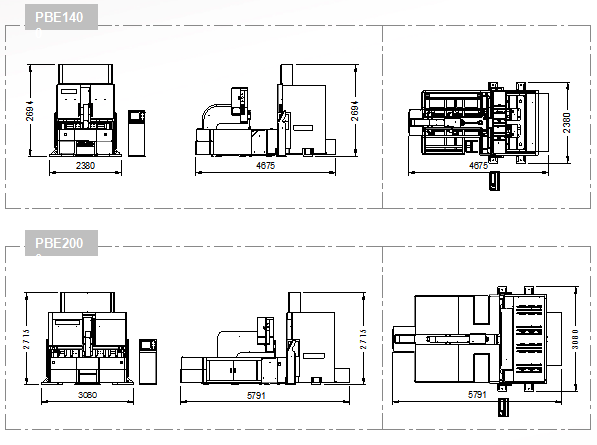

Machine Installation Layout

Vessel Container Required

* The best way for BEC SMART 2000 delivery is 20OTx1 and 20GPx1 because of over height.

Specifications

Name | Unit | BEC SMART-1400 | BEC SMART-2000 | BEC SMART-2500 | |

|---|---|---|---|---|---|

Max. Bending Length

| mm

| 1400

| 2000

| 2500

| |

Max. Sheet Width

| mm

| 1500 | 1500 | 1500 | |

Max. Bending Height | mm | 170 | 170 | 170 | |

Min. Workpiece Size

(four sides bending) | mm | 110×200

| 110×200

| 110×200

| |

Min. Workpiece Size

(single side bending)

| mm | 110

| 110

| 110

| |

Min. Radius

| mm

| 1.2

| 1.2

| 1.2

| |

Bending Angle

| °

| ±180

| ±180

| ±180

| |

Max. Bending Speed | s/bending | 0.5 | 0.5 | 0.5 | |

Min. Sheet Thickness | mm | 0.35 | 0.35 | 0.35 | |

SS | mm | 1.0 | 1.0 | 1.0 | |

Max. Sheet Thickness | MS | mm | 1.5 | 1.5 | 1.5 |

AL | mm | 2.0 | 2.0 | 2.0 | |

Dimensions(L×W×H) | mm | 3100x5300x2600 | 3100x6050x2600

| 3100x6050x2600

| |

Full Power

| KW

| 380V±10% | 380V±10% | 380V±10% |