ACCURL

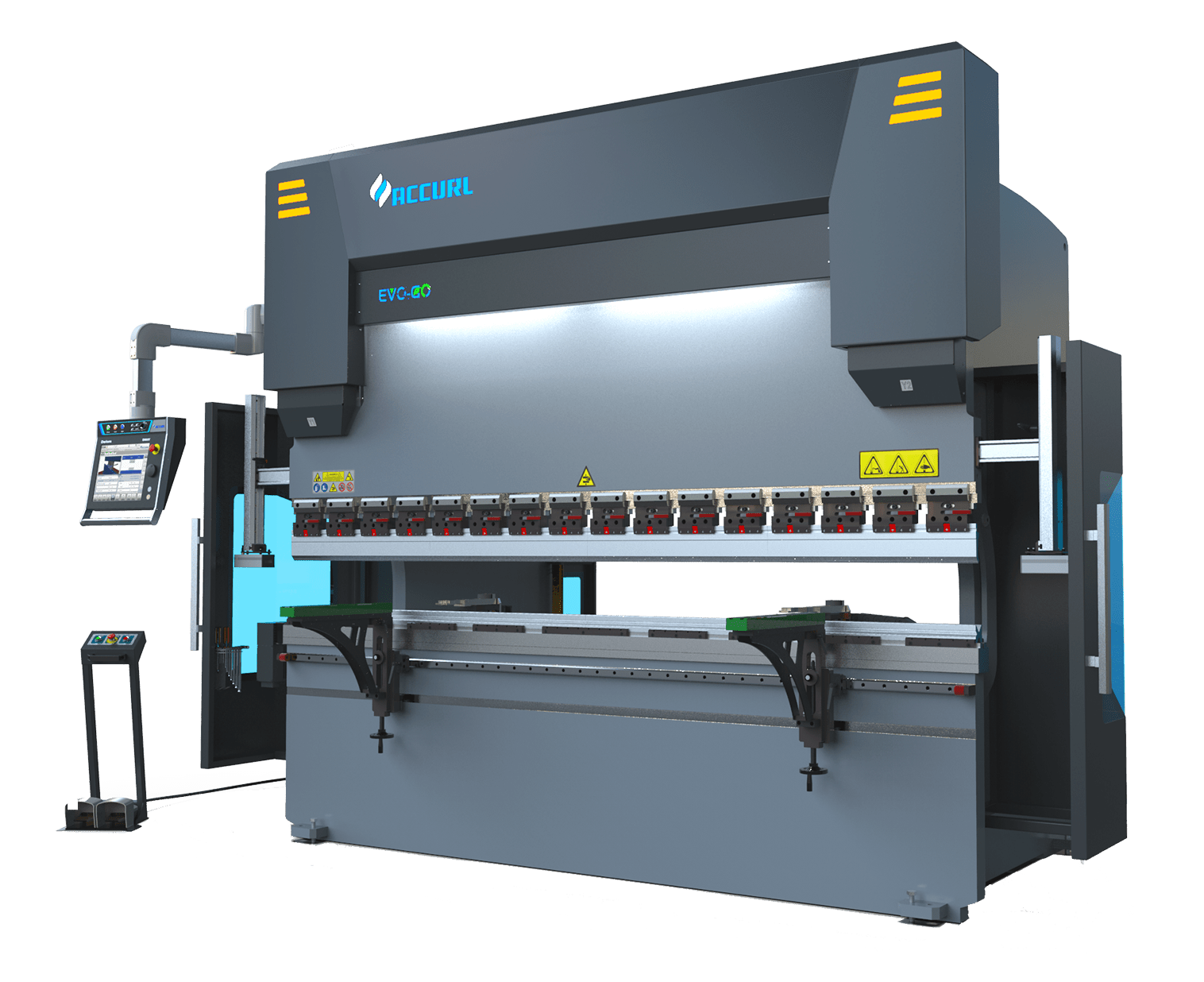

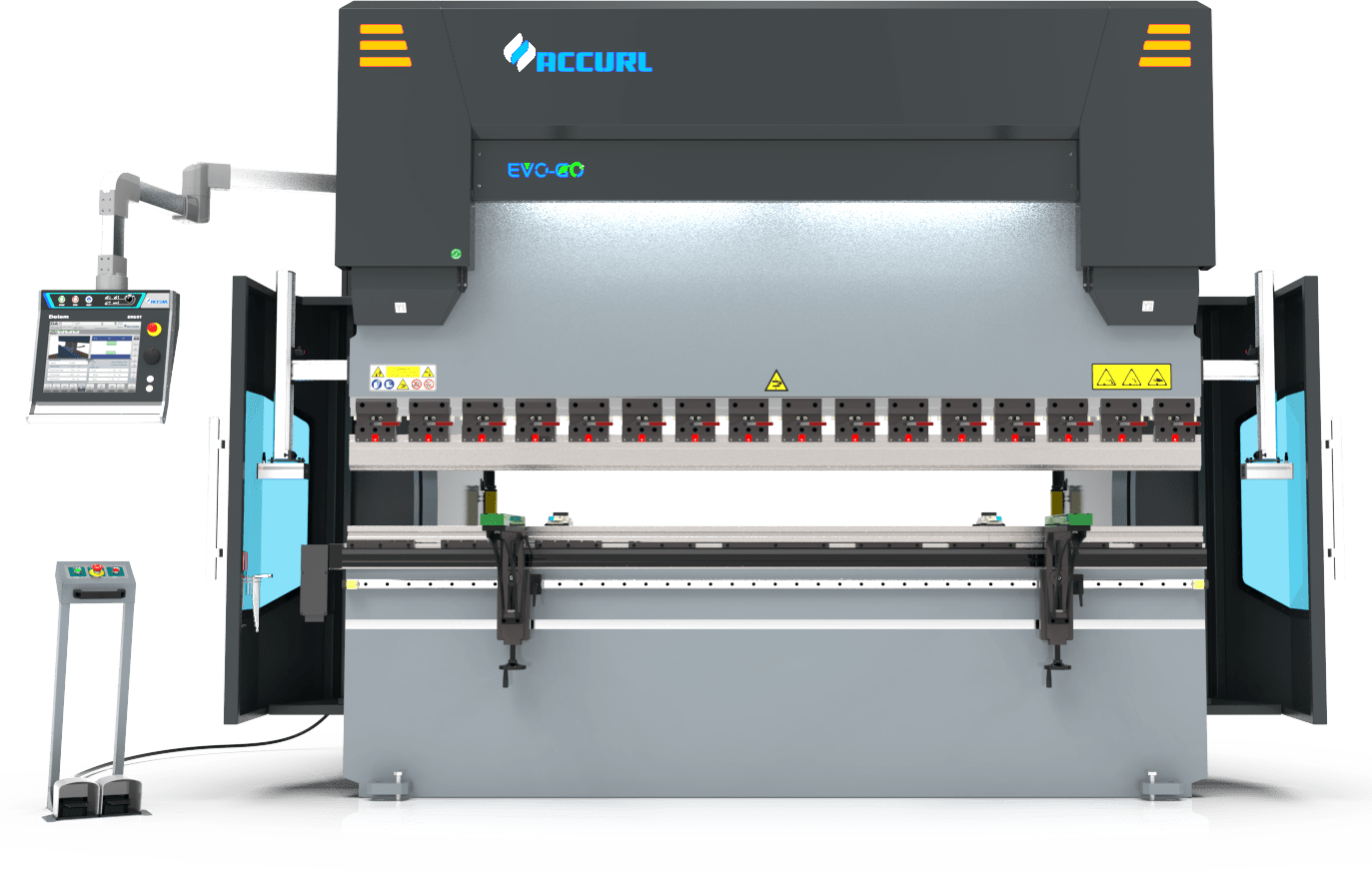

Hybrid Genius Plus B Series 6~8-Axis CNC Press Brake

ACCURL

ACCURL Genius Plus Series 6 ~ 8-Axis CNC Press Brake

CNC Press Brake For Quiet Operation With Large Daylight & Stroke

ACCURL® New Genius Series Hybrid servo CNC press brake Based on proven design Pro Series has increased working speeds, stroke, daylight & pressing capacities. With advanced motion technologies and impressively quiet with the most flexible features and options, the Genius model is the ultimate in creating complex parts.

The ACCURL Hybrid Servo ECO system is an innovative servo drive for press brakes, and thanks to DELTA servo motor, we can precisely control the movement of the ram using a minimum amount of oil and energy

ACCURL Genius Plus Series 6 ~ 8-axis

Includes Following Features And Configuration

Less Waste, Less Maintenance

High Performances

Same Job, 50% Less Energy

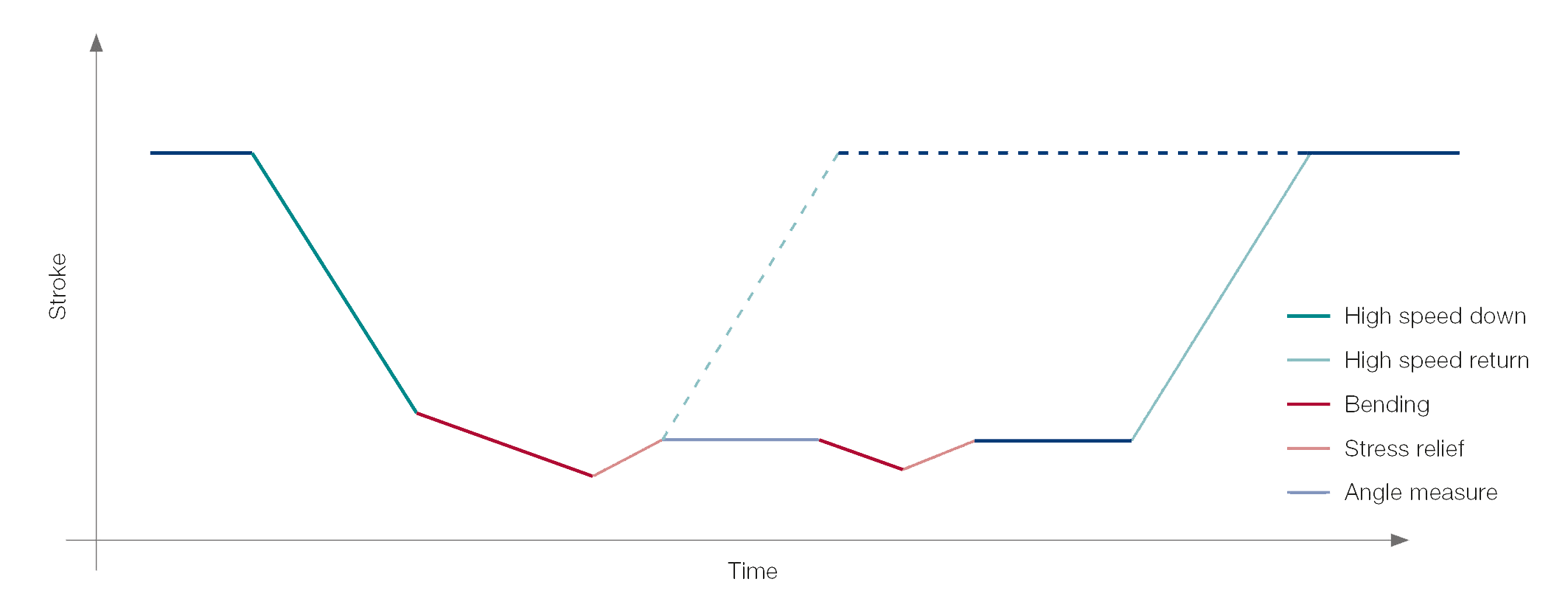

<High Dynamic Y-axis Control

<Over 30% higher productivity

Standard Equipment

- CNC DELEM DA66T with 2D color graphics

- ACCURL® BGA-4 for X=600mm X, R, Z1, Z2-Axis

- ACCURL® Hybrid Servo ECO Function

- Tool kit: 4 V die (V=16-22-35-50) series of 835mm punches

- ACCURL Pro CNC wave crowning system

- GIVI optical scales

- Lazersafe Systems LZS-2 Block Laser

- Hoerbiger (HAWEI) hydraulic system

- High efficiency motor – class IE3

- DELEM® Profile T2D Offline Software

- Electrical cabinet with Schneider, Siemens components

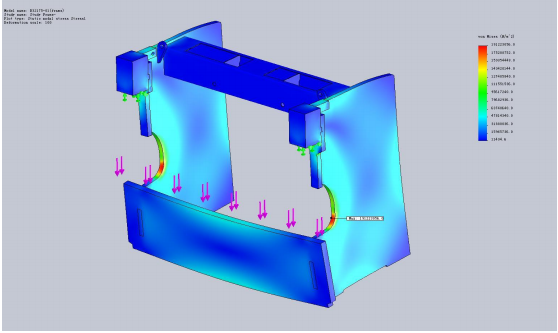

FEA & Stress Analysis

The CAE software SOLIDWORKS used as the method to analyze the linear static construction, stress and deformation for press break and laser cutting machine frames. So for complicated structures, highly complex loading’s, transient modelling and combination of the above, FEA makes sense.

Over 35 Years Of Experience In Top Level Controls

Successfully controlling precision & productivity, modern sheet metal production is inconceivable without high performance software. Highly effective control algorithms optimize the machine cycle, reduce the time required for set-up and ensures consistently high quality.

ACCURL is one of the world’s leading manufacturers in the field of steel metal working machinery for our Laser Cutting Systems & Press brakes.

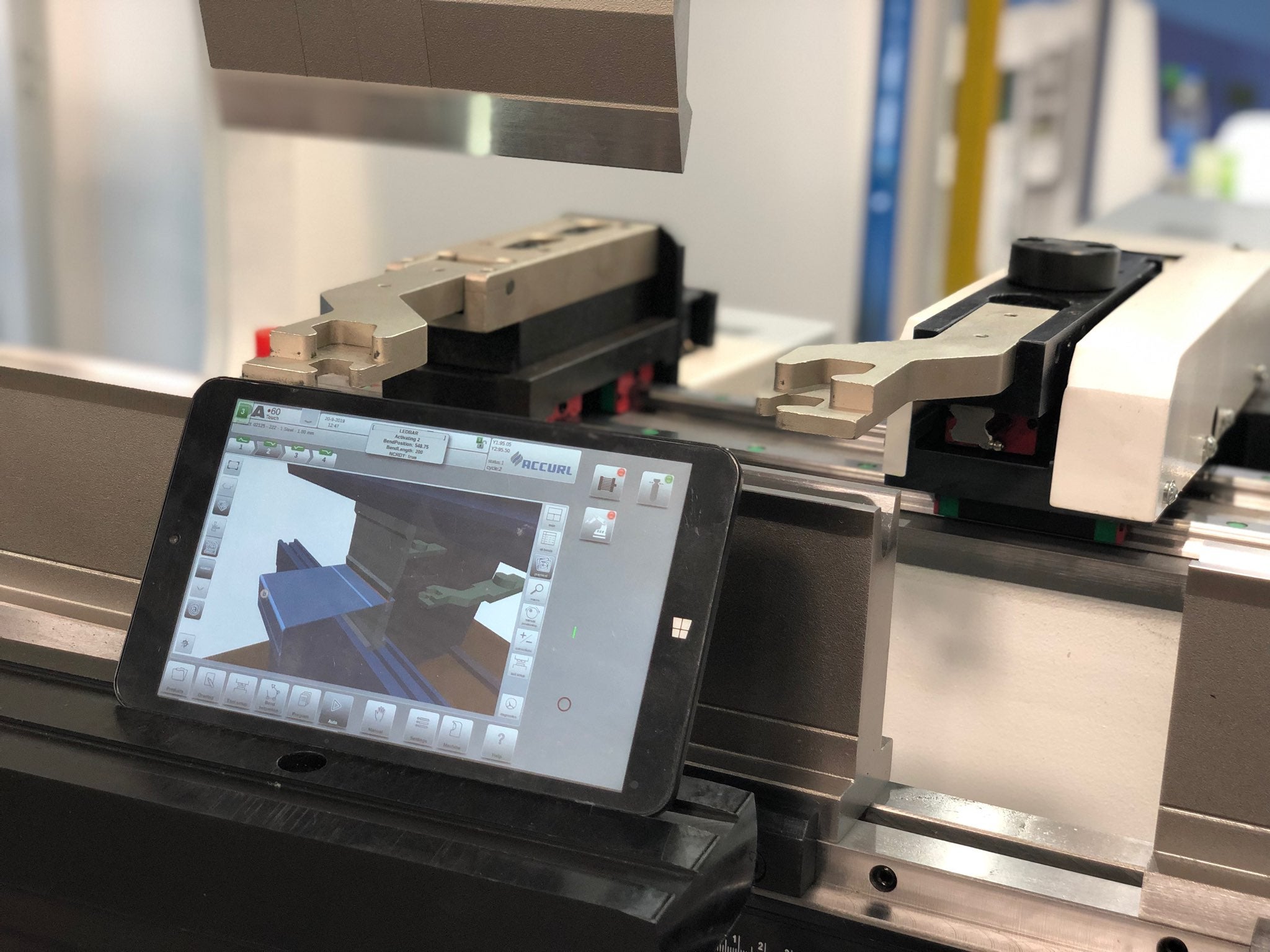

DELEM DA66T Touch 2D Graphical Control

- 17" high resolution colour TFT

- 2D graphical touch screen programming mode

- 3D visualisation in simulation and production

- Full Windows application suite

- Delem Modusys compatibility (module scalability and adaptivity)

- USB, peripheral interfacing

- Profile-T2D offline software

- Sensor bending & correction interface

Press Brake 4-Axis CNC BackGauge with X, R, Z1, Z2-Axis

- Ball screws and linear guide on X, R-axis.

- Precision belts and YYC rack on axes Z1‐Z2.

- Fingers with double stop and micrometric adjustment.

- Mechanical accuracy ± 0.03 mm.

- Axes Z1‐Z2 speed 1000 mm/s.

- Axis X speed 500 mm/s.

- SPA Thin supports system in the fingers.

- Load capacity – 30 kg per support.

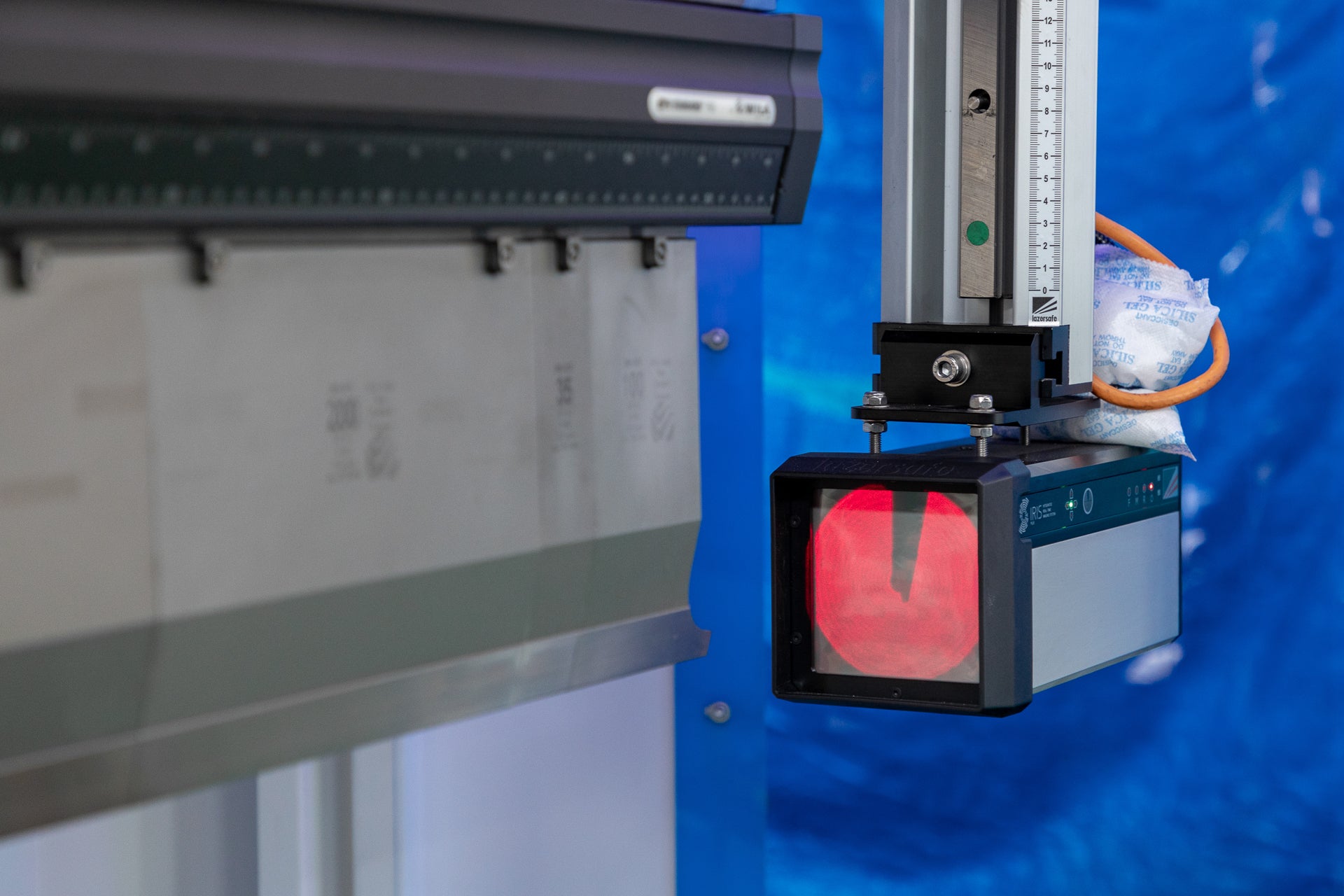

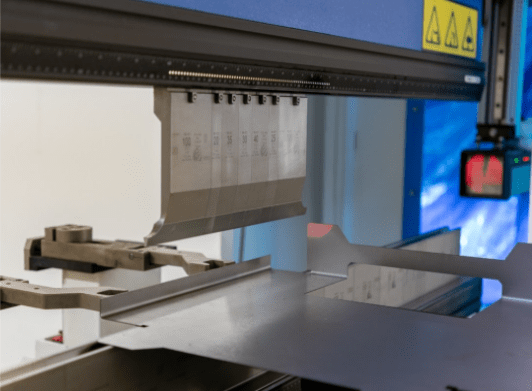

Lazer Safe - Performance Without Compromise

Optical Safety System - Advanced

ACCURL® CNC press brake use OEM EMBEDDED LAZERSAFE offers a highly effective solution for both operator safety and machine productivity. Designed for use with Lazer Safe’s PCSS A Service, the Lazersafe is category 4 compliant and meets the world’s most demanding international safety standards(CE Certified Category 4 Safety Controller with integrated).

Optional:

- Lazersafe-PCSS A0 LZS-XL

- Lazersafe-PCSS IRIS

ACCURL PPO® family CNC Crowning:

The ACCURL Pro® Adaptive CNC Crowning system enables theuser to offset deformations of the beam while bending. thus, the angle iskeeping constant along the entire plate length.

Advantage:

- Easy reversibility of tools because of symmetrical adaption

- Hand crank with digital readout or CNC electric drive connected direct to the machine

- Hardened to 28–32 HRC which makes it substantially tougher than the competition

- Micro crowning every 200mm

- T & Y adjustable 0–0.76mm (0–0.030")

Wila Hydraulic Clamping System:

The Wila’s ‘New Standard’ Tooling System has become market leader for precision, quality and flexibility for the Accurl hydraulic press brakes for sale, the WILA’s state-of-the-art clamp system

Advantage:

- Long service life: >10 years

- Quick clamping for WILA style tooling

- Simple push-button loading

- Fast and safe tool changes: Reduce 80% time

- High-precision bending angle and flange edge

ACCURL New Hybrid Servo ECO Function.

ACCURL® promotes a friendly environmental policy, and as such all our equipment features the Hybrid ECO Function. Our hybrid servo-drive positioning system provides accuracy at any position.

Advantage:

- High dynamic for a higher productivity of the machine.

- Compliance with EU Directives.

- Lower energy for a green Machine.

- Lowered sound pressure level at 50 dB.

- The servo-motor, with closed loop speed control.

- Energy efficiency of up to 35 % compared to conventional systems.

- Operating cost is min due to low energy consumption. thus, it gives advantages to the user with high efficiency & low operation cost.

Indispensable Tool To Increase Profitability

Profile T3D Offline Programming:

Industry 4.0 With IOT Productivity Monitor™

Thanks to the advanced ACCURL® CNC and interconnecting ad-hoc software tools like the “Smart Factory” make it possible for companies to enter industry 4.0 that is revolutionizing the reality of companies. you can extract data and share information at company level: bending programs, sensors, production statistics.

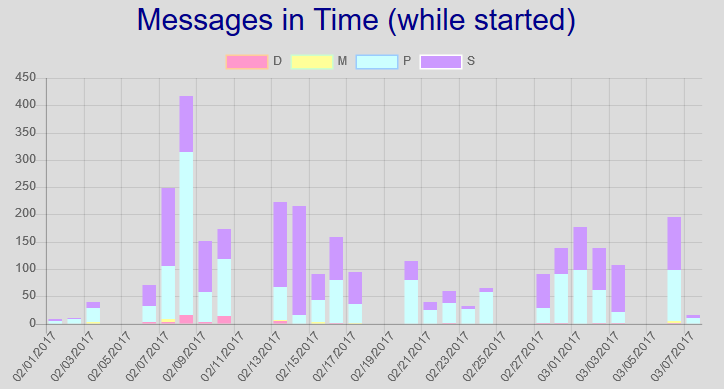

Messages In Time

- D = messages from the Delem application

- M = messages from a DM-module

- P = messages that are generated by a safely PLC

- S = message generated by the sequencer

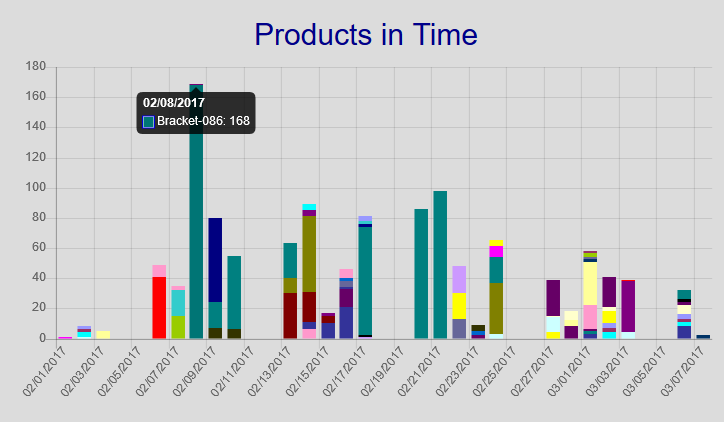

Products In Time

This block displays a bar graph indicating for each product the amount that has produced per day. When the mouse cursor is moved onto one of these bars, the product ID and the amount for that date is displayed.