ACCURL

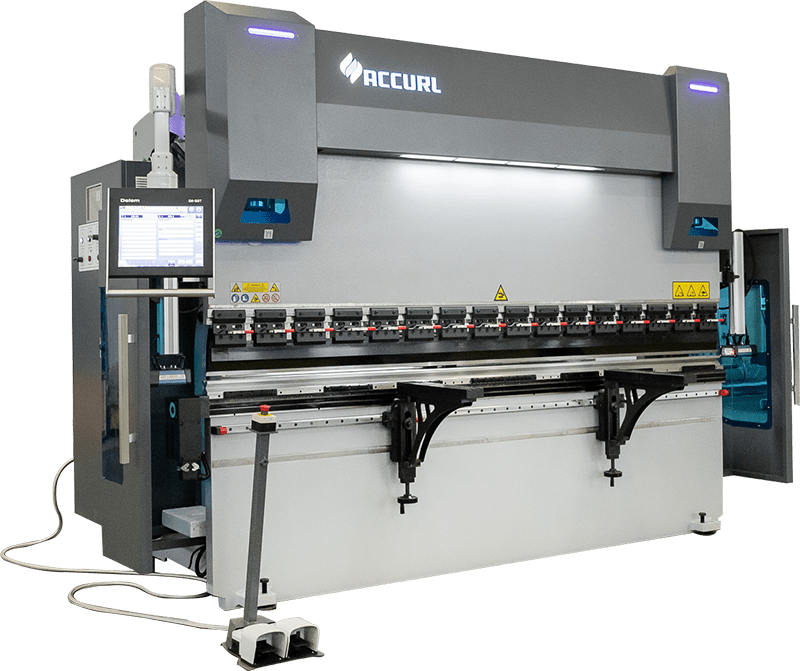

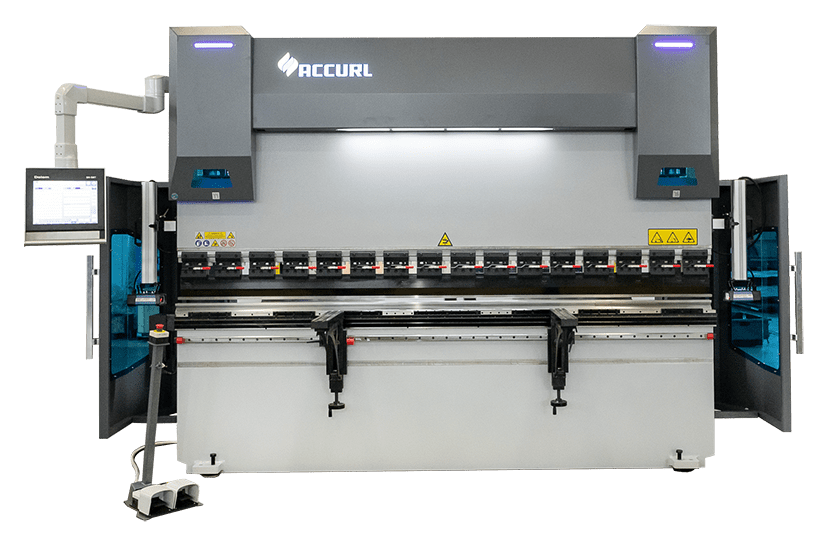

Small Press Brake - Smart 3-4 Axis

ACCURL

Simple Small Cnc Press Brake Machine For Sheet Bending

Superior Quality. Reliability In An Economical Machine

ACCURL® SMART Series is an affordable small CNC press brake with an impressive number of features and options.

Competitive pricing with advanced DELEM DA53T 2D capable graphical controls or Cybelec CybTouch 8PS, and that customers can also choose ESA S630 or ESA S640W CNC control system.

Smart Series is your first choice in Y1/Y2 machine technology.

ACCURL Economic Smart Series

Includes Following Features And Properties

Less Waste, Less Maintenance Costs

High Performances

Same Job, 50% Less Energy

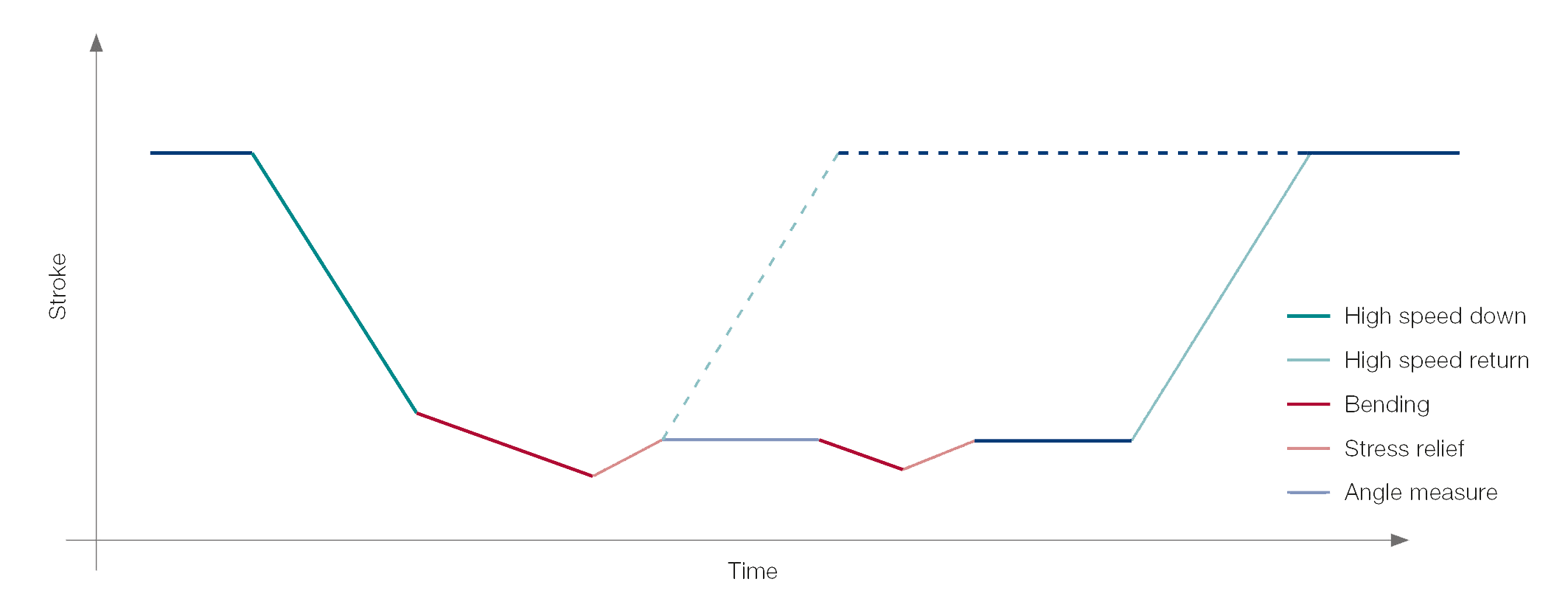

<High Dynamic Y-axis Control

<Over 30% higher productivity

Standard Equipment

- CNC DELEM DA53T with 2D colour graphics

- ACCURL® BGA-2 for X=500mm X,R-Axis

- Tool kit: 4 V die (V=16-22-35-50) series of 835mm punches

- ACCURL Pro Manual wave crowning system

- GIVI optical scales

- Lazer Safe dual beam photocells

- Hoerbiger (HAWEI) hydraulic system

- High efficiency motor – class IE3

- Electrical cabinet with Schneider, Siemens components

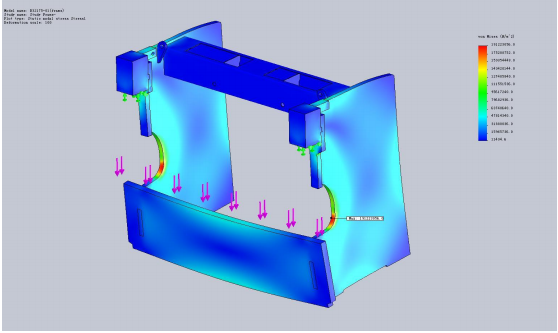

FEA & Stress Analysis

The CAE software SOLIDWORKS used as the method to analyze the linear static construction, stress and deformation for press break and laser cutting machine frames. so for complicated structures, highly complex loading’s, transient modelling and combination of the above, FEA makes sense.

Over 35 Years Of Experience In Top Level Controls

Successfully controlling precision & productivity, modern sheet metal production is inconceivable without high performance software. Highly effective control algorithms optimize the machine cycle, reduce the time required for set-up and ensures consistently high quality.

DELEM CNC Control System

DELEM DA53T Touch CNC System

- 10.1" high resolution colour TFT

- “Hot-key” touch navigation

- Up to 4 Axis (Y1,Y2 + 2 aux. Axis)

- Tool / material / product library

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- CNC Crowning control

- USB memory stick interfacing

- Profile-53TL offline software

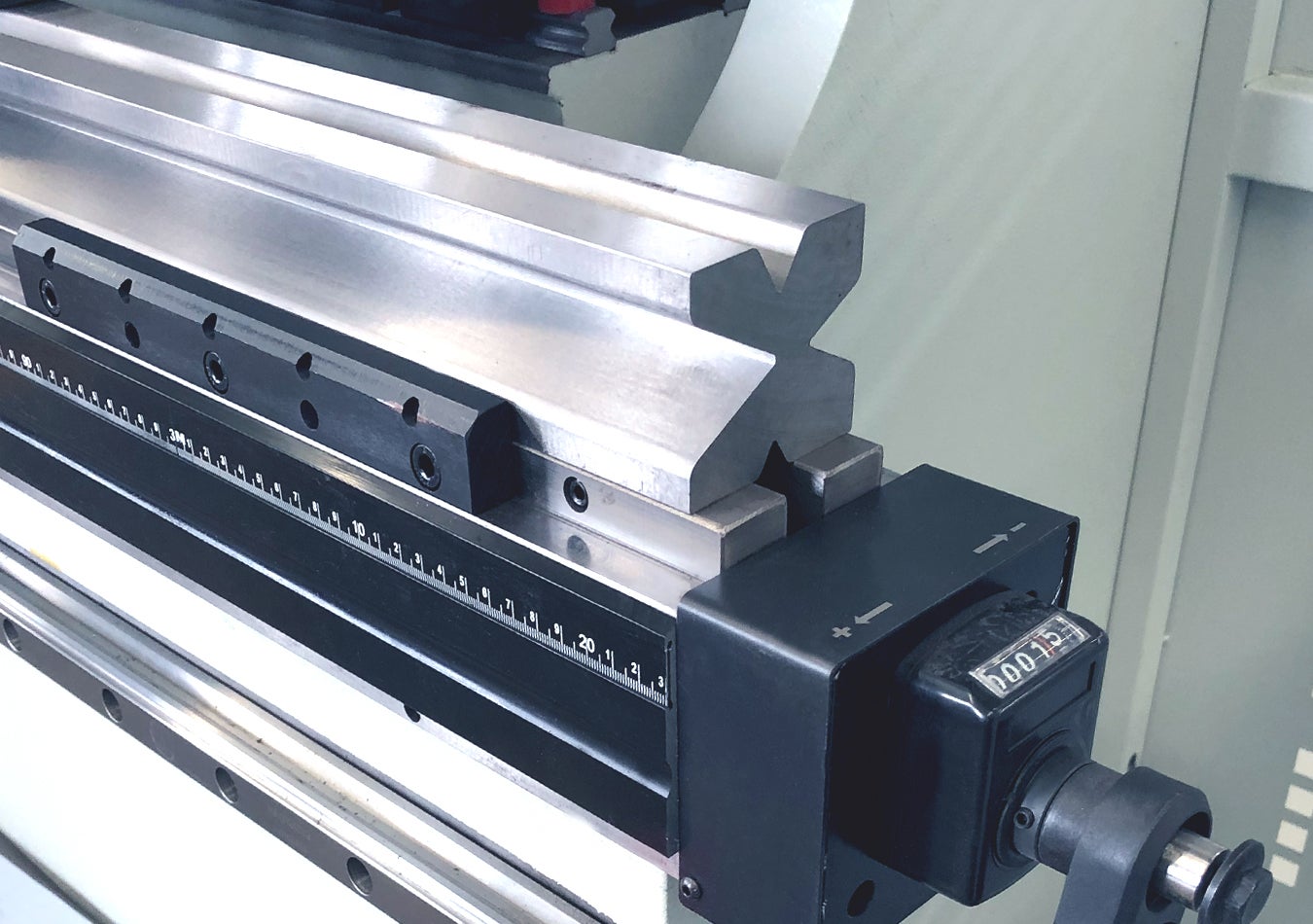

Press Brake 2-Axis CNC BackGauge

with X, R-Axis

- Ball screws and linear guide on X, R-axis

- Axis X speed 500 mm/s.

- Manual Z1, Z2-axis with HIWIN linear guide

- Mechanical accuracy ± 0.03 mm.

- Fingers with double stop and micrometric adjustment.

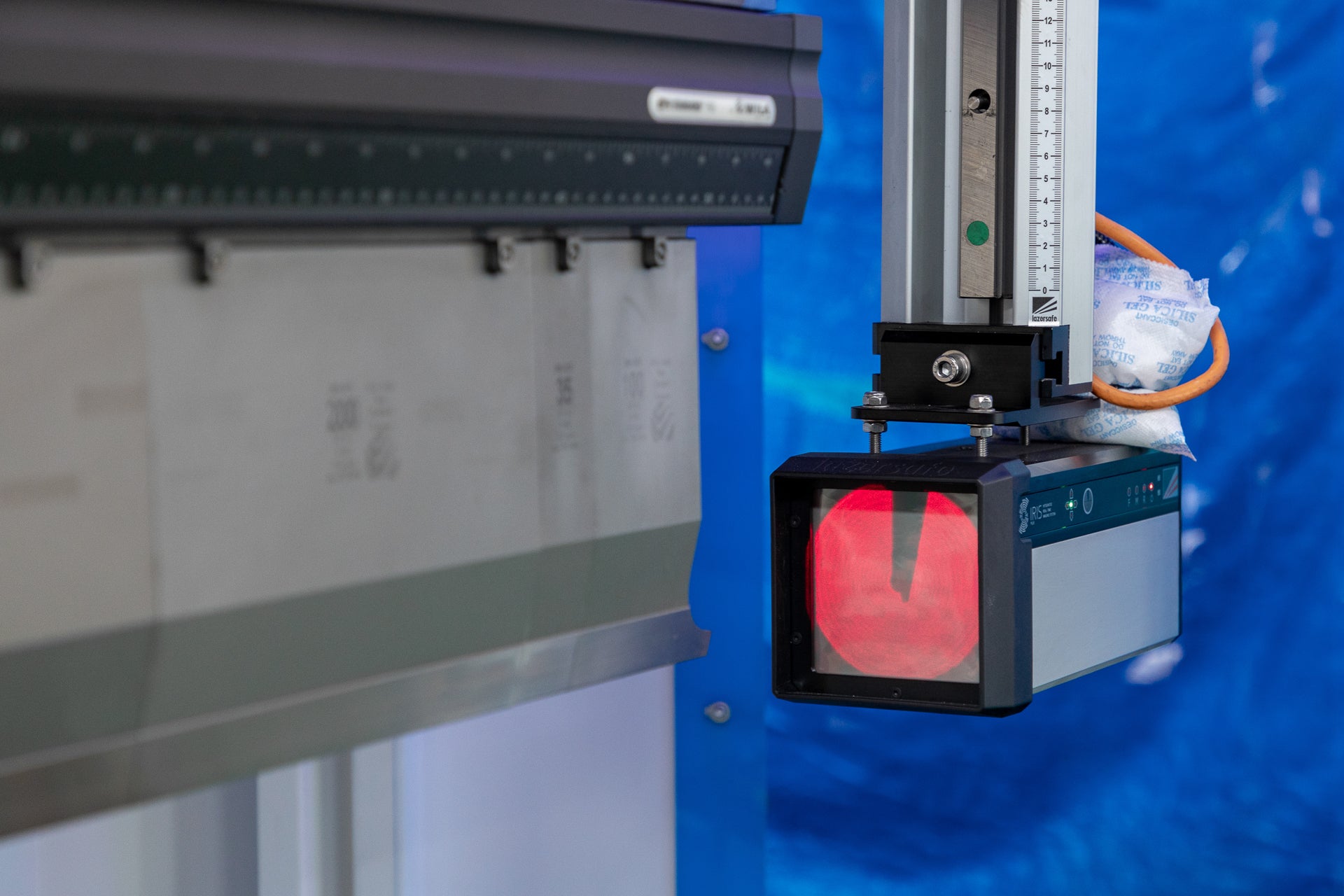

Lazer Safe - Performance Without Compromise

Optical Safety System - Advanced

- CLASS 1 Dual Block laser

- Fast response time

- Safety speed automatically monitored

- Stopping distance automatically monitored

- Status LEDs - Power / Front/middle/rear Sensors

- Tray mode for high speed bending of tray & box shapes

- Complex shapes can be achieved in high speed with Tray/Box Mode.

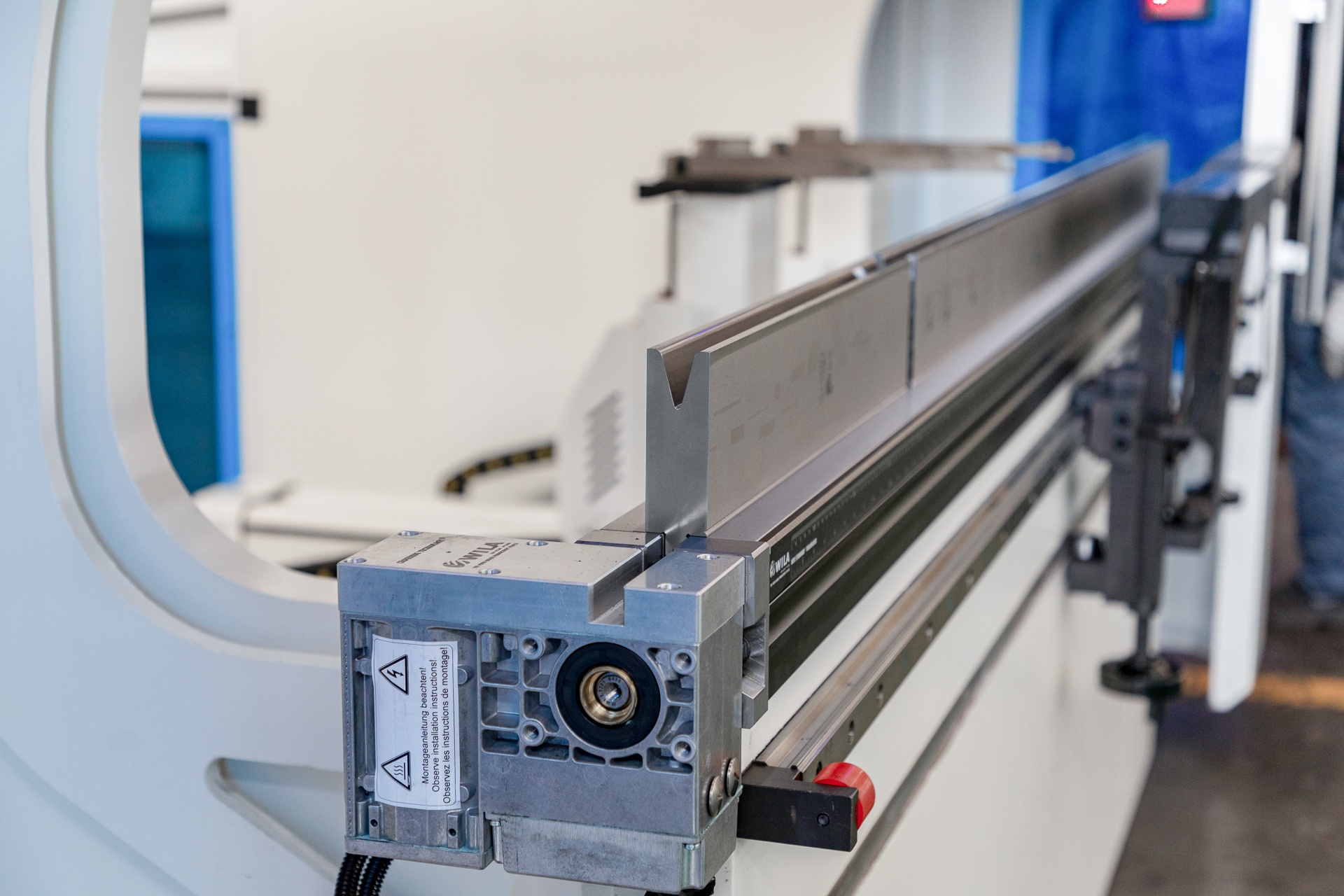

High Precision & Adaptive Crowning System

By avoiding machine deflection, the ACCURL Crowning™ System creates precise parts, consistently parallel with every run.

ACCURL PPO® family Manual Crowning:

- Very precise bending angles

- Europe type dies with 60 mm and 90 mm

- Base can be clamped as well as single dies with 13 mm tang

- Manual crowning with a handle

- Precise positioning and alignment of the crowning table

- Easy and fast usage

Manual Upper Tool Clamping:

ACCURL CNC press brake use all Raw material is provided by qualified suppliers and chemical composition corresponds to international standards. Therefore, raw material yield and tensile strength are guaranteed, are standardized with a 8.4 x 3.5 mm safety groove, which keeps the tool from falling out.

Advantage:

- Safe and fast tool change

- Can be used without modifying Europe type punches

- Front clamp - vertical tool change

- Rear clamp - horizontal tool change

ACCURL New Hybrid Servo ECO Function.

ACCURL® promotes a friendly environmental policy, and as such all our equipment features the Hybrid ECO Function. Our hybrid servo-drive positioning system provides accuracy at any position.

Advantage:

- High dynamic for a higher productivity of the machine.

- Compliance with EU Directives.

- Lower energy for a green Machine.

- Lowered sound pressure level at 50 dB.

- The servo-motor, with closed loop speed control.

- Energy efficiency of up to 35 % compared to conventional systems.

- Operating cost is min due to low energy consumption. Thus, it gives advantages to the user with high efficiency & low operation cost.