ACCURL

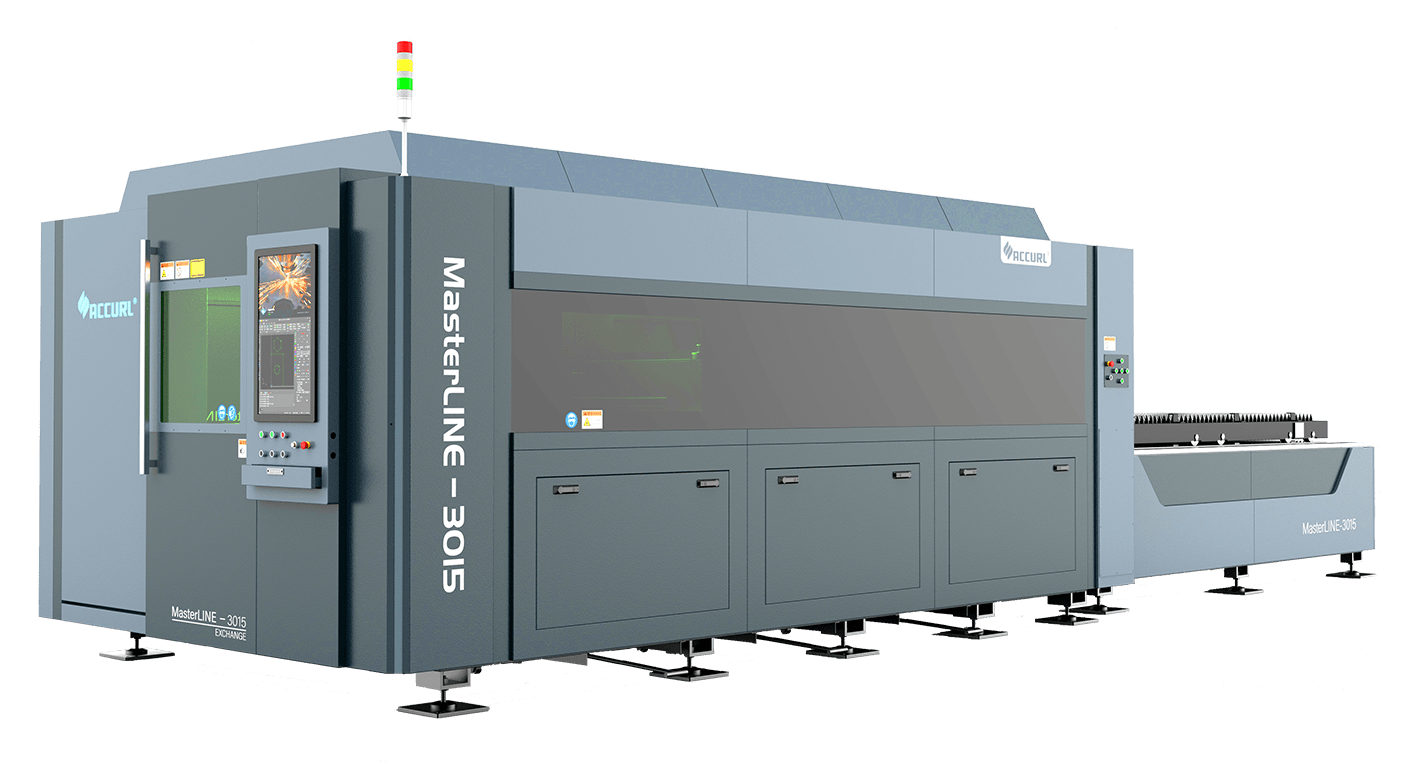

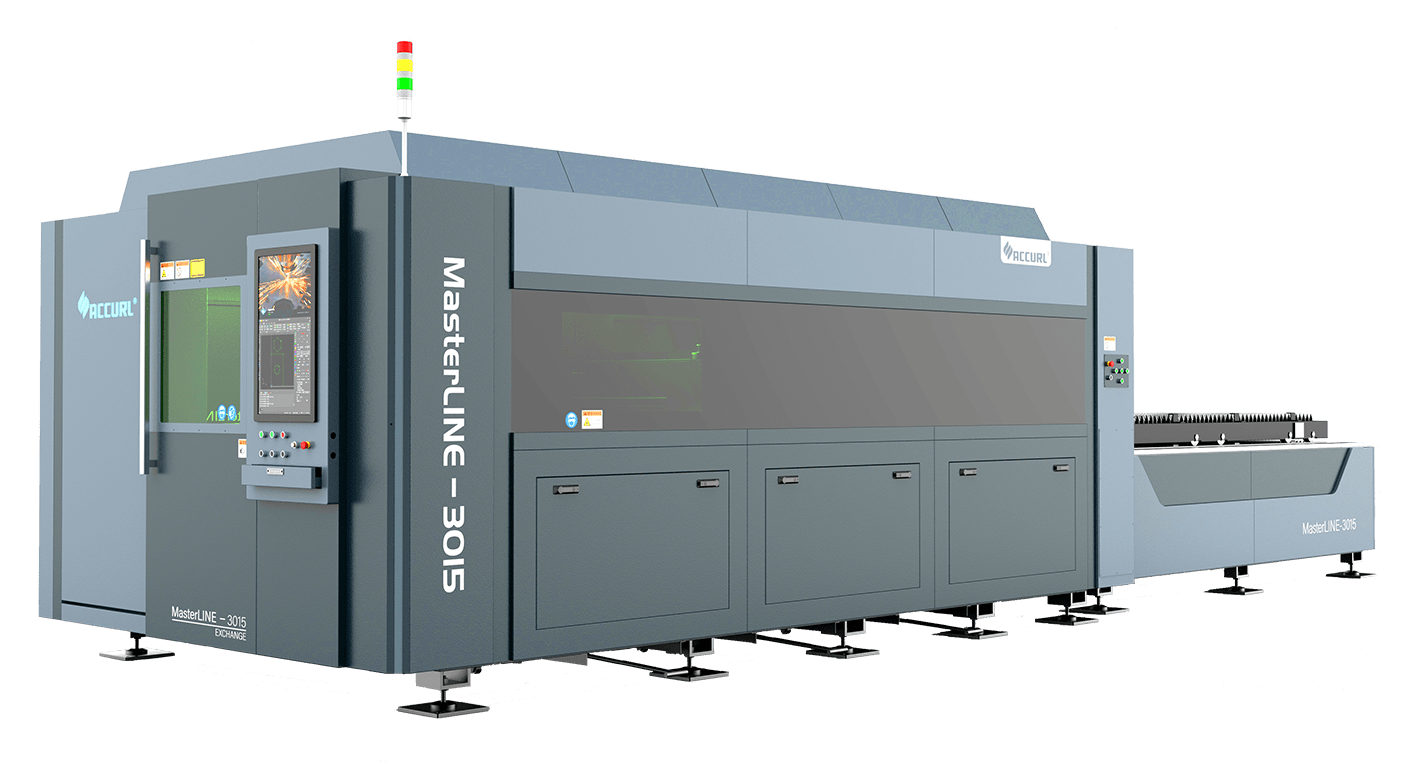

MasterLINE 6Kw-15Kw Fiber Laser Machine

ACCURL

MasterLINE 6Kw-15Kw Fiber Laser

MasterLINE 6Kw-15Kw Fiber Laser

Includes Following Features And Configuration

Flexible

Reliable

Profitabie

User Friendly

Why Accurl Laser Cutting?

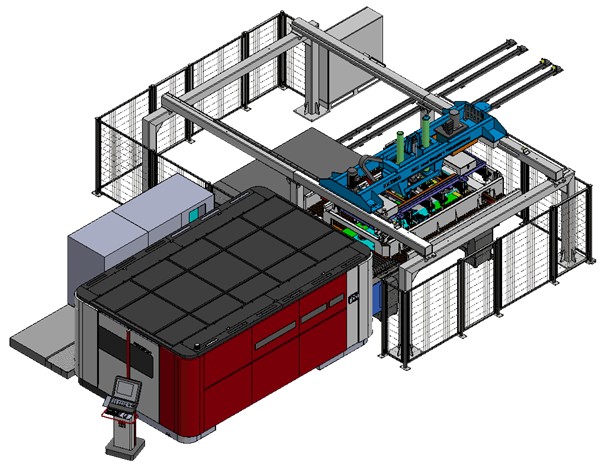

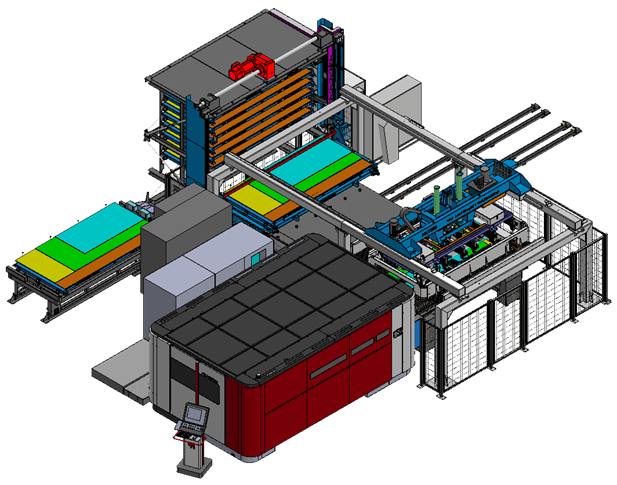

Innovative Modular Design

- Our machines can also be combined with automation modules to create a complete system for the whole working process.

- Customized solutions at a reasonable price, from basic to high end machine.

Experience

- 33 years of experience and more than 12,000 installed machines.

- An expert R&D team committed to research the most competitive technology for our customers.

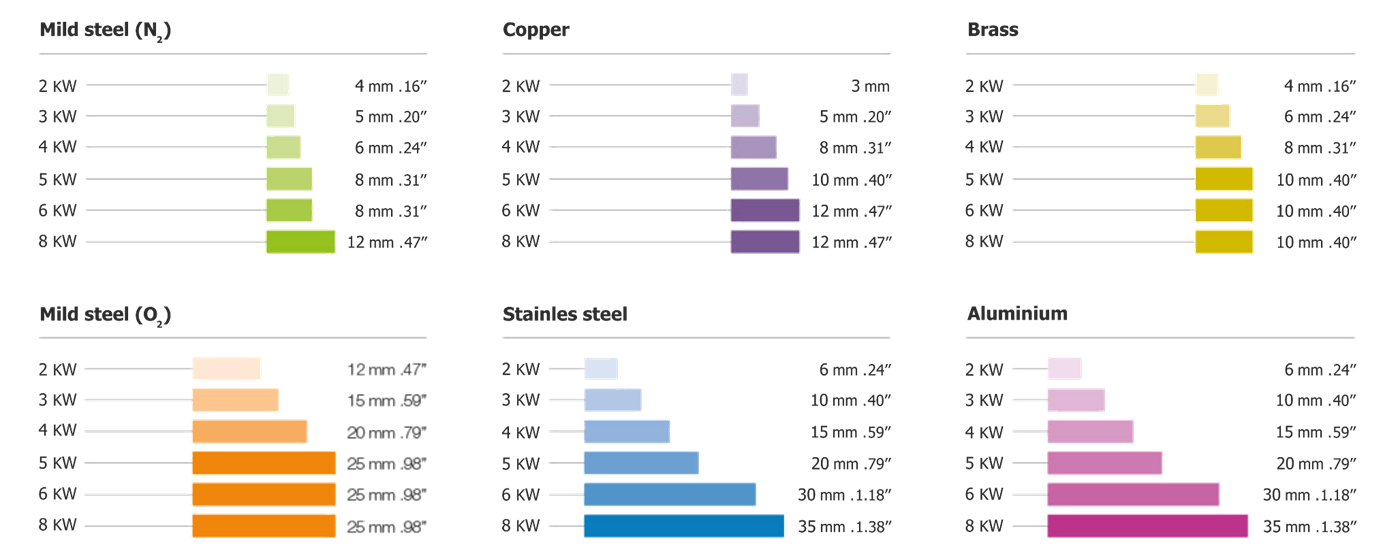

More Varied Solutions for Cutting

- Sustainability and social responsibility are characteristics of modern companies and add to competitiveness.

- Comprehensive range of basic tools in stock and modified solutions according to customer needs.

ACCURL High Quality Equipment

- The critical parts of the Accurl laser machine are manufactured in Germany.

- We rely on our quality and therefore give our laser cutting machine a 3-year warranty.

- The IPG Fiber resonator. Power from 1Kw To 30kW.

After-Sales Service

- Original ACCURL spare parts to guarantee full performance and prolonged durability.

- Wide range of consultation services on machine operation, programming and maintenance.

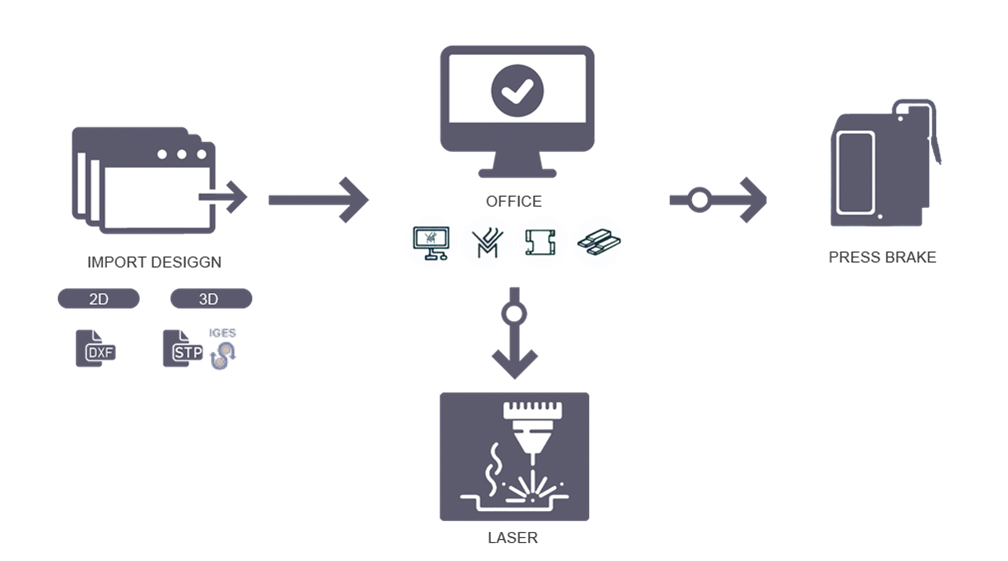

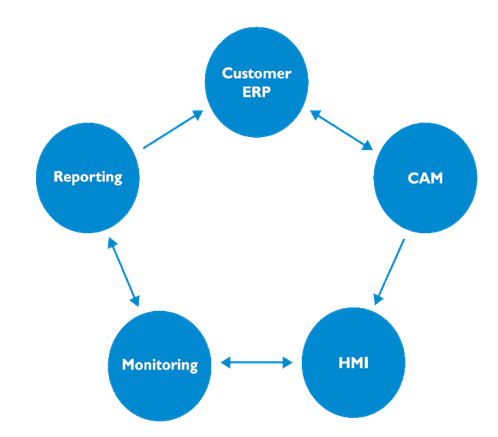

Software And CNC: User-Friendly And Effcie™

Customer ERP connection

Importing of production list order from customer ERP.

Human Machine Interface

Interacting in an easy and friendly way, through touch screen, with the machine and relevant automation.

Production and Performance data Reporting

Proprietary solution for viewing reports of machine status and analyzing production data.

Cam programming / 2D Cam and Tube Cam

Efficient pogramming for a productive fabrication process:

• Powerful nesting .

• Optimized Post Processor for 2D cut programming and tube cut programming .

• Powerful simulation.

Monitoring / Production Control

Monitoring machine statuses and task lists and displaying all the events of all the machines in one view.

Jobshop 4.0 By Libellula

The system of performing and integrating software solutions to manage every metal sheet working phase in a productive and efficient way.

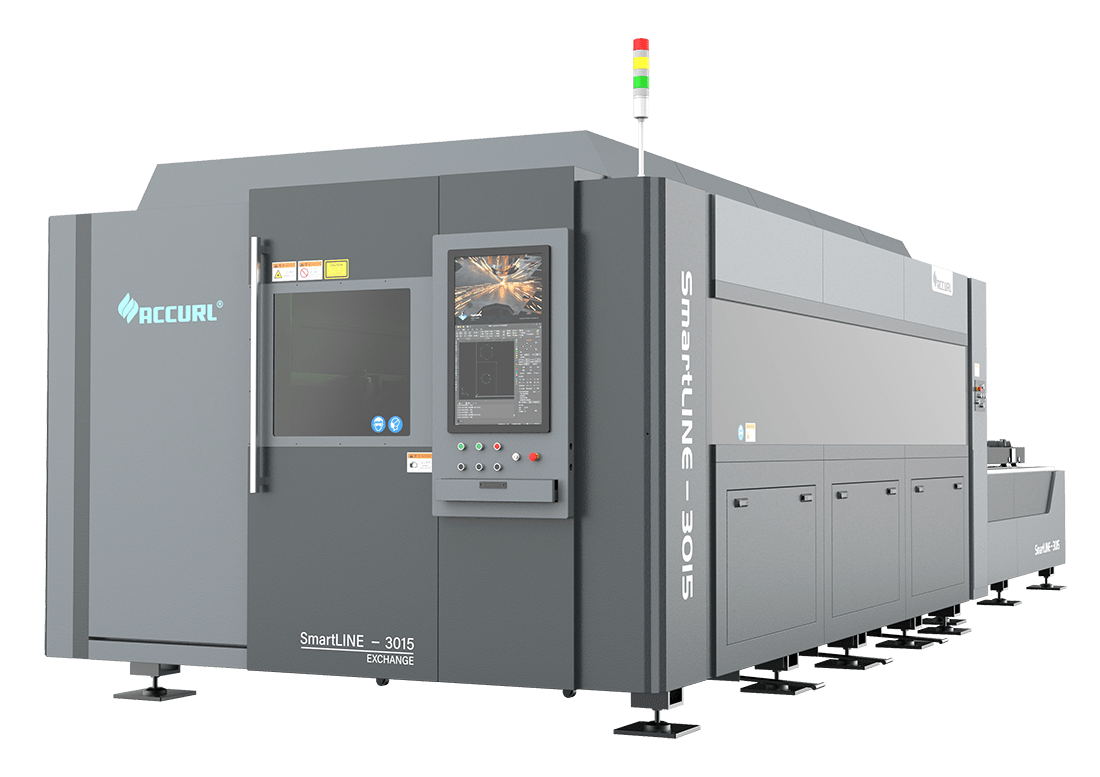

Compact and technological for outstanding performance

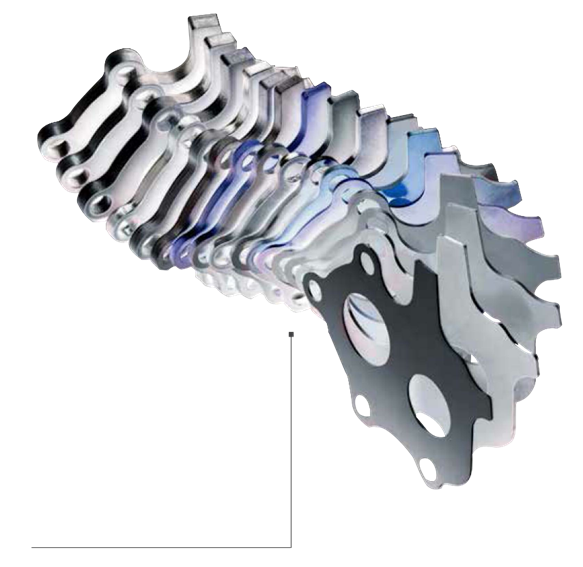

Flexible

Suitable for a wide range of materials, including highly-reflectie metals and high thickness mild steel. Ready for round, square and rectangular tubes.

Reliable

Fully-tested and reliable thanks to the 20 years of experience with the MasterLINE platform.

Profitabie

Low operating costs thanks to energy efficiencyand reduced maintenance.

User Friendly

Single focusing lens system with automatic nozzle changer. Easy to use programming software and Accurl operator interface.

Quality Steel Frames

ACCURL steel frames undergo annealing at over 600⁰ to relieve stress. and they are built to last years of heavy use without distortion.

Advantage:

- Very stiff and stable base frame

- Deformation simulation made by CAE

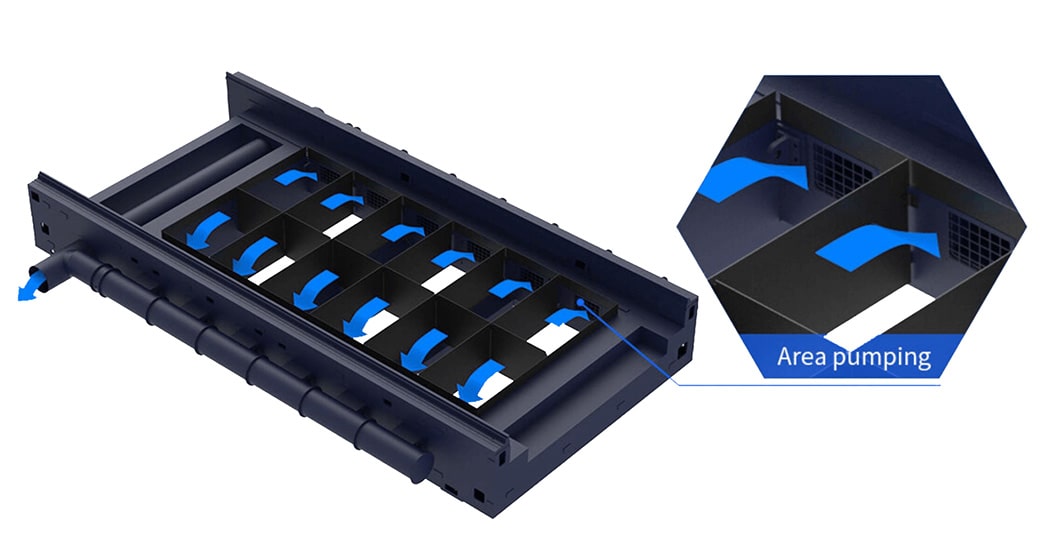

- Eight(8) zone & ducted exhaust system

- Dual synchronized twin servo motor drive system

- Helical rack & slant pinion drive system enables very smooth Movements.

Fully Annealed Frame

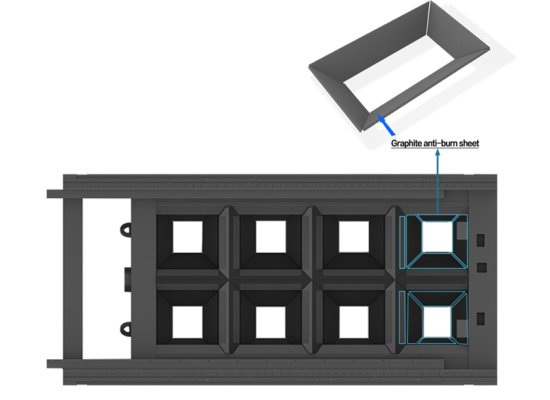

Graphite Anti-burn Technology

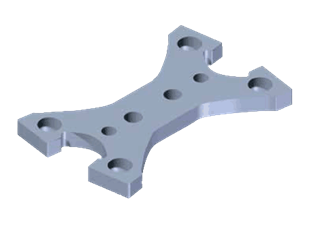

Aluminium Gantry Structure

The gantry is a monolithic structure made from a single aluminium casting. This technological solution is ideal for structures subjected to high levels of mechanical stress.

With the multi chambers high efficient system ofers the ability to make an equal amount ofsuction during the cutting operation of the whole machine cutting area.

Cast Aluminium Gantry

ACCURL® high tech aluminium crossbeam is cast in a specially manufactured 10-tonne steel mould. this allows better rigidity at 50% of the weight of traditional iron gantries, allowing higher acceleration with reduced inertia.

Fume Extraction System

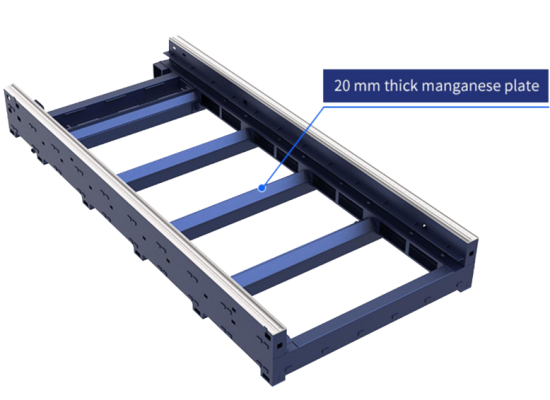

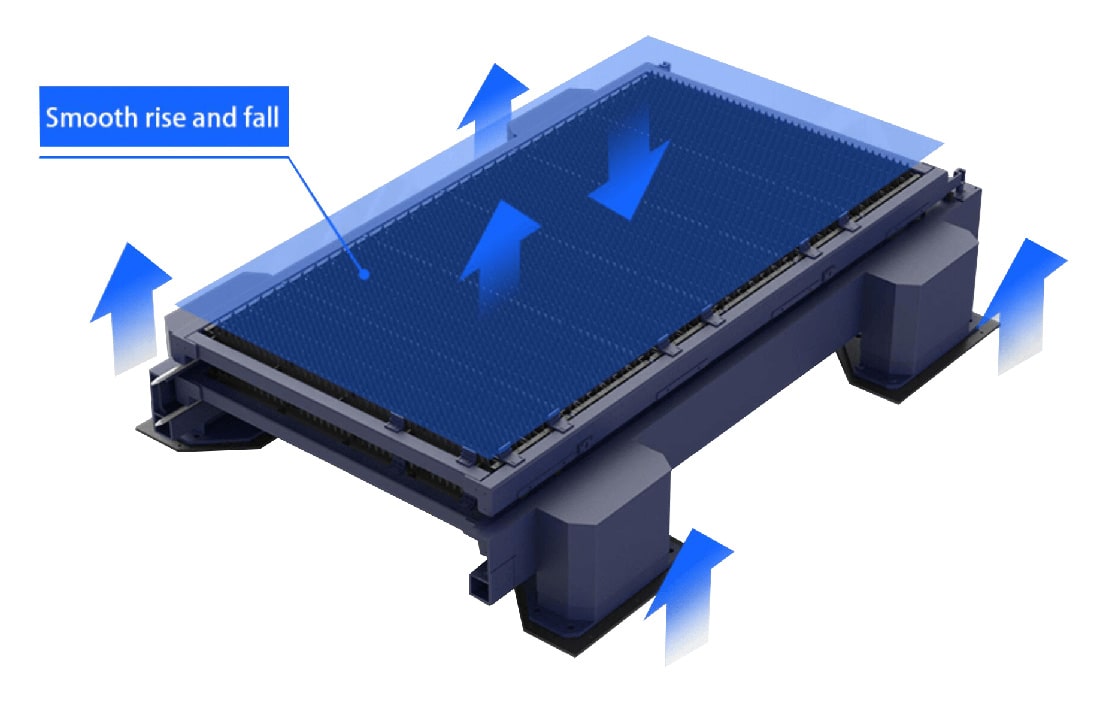

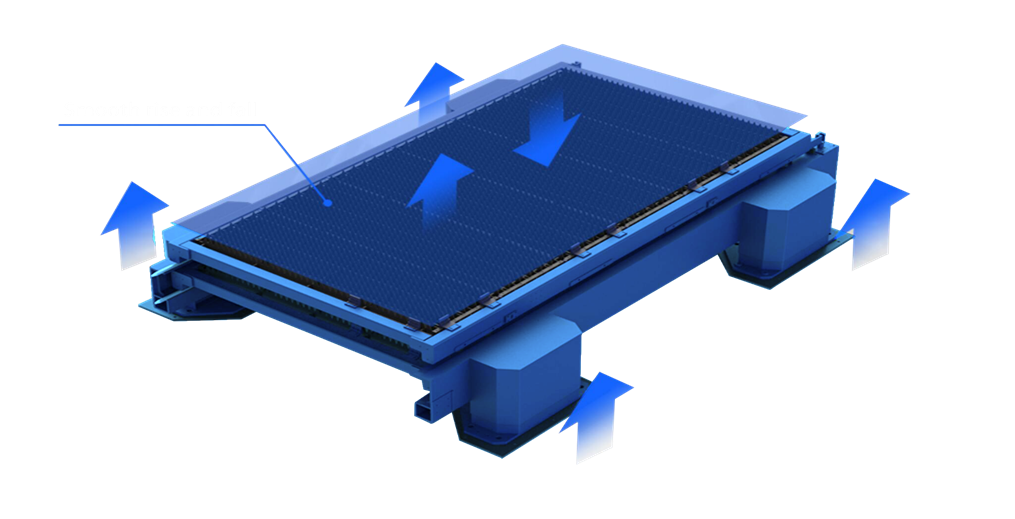

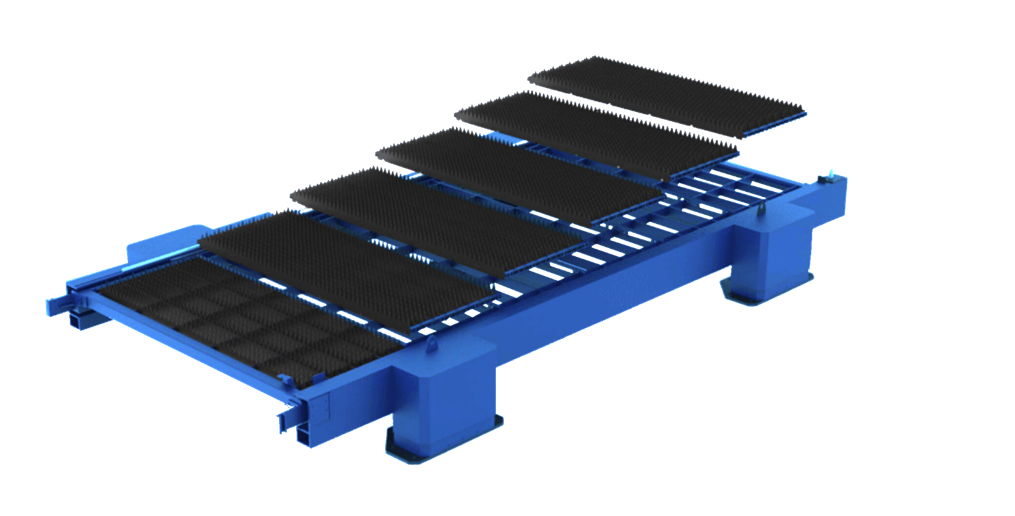

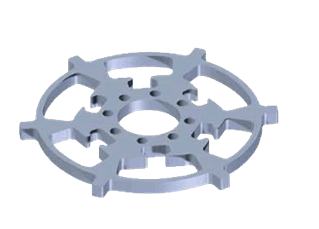

Auto Changing Pallet Table System

Auto Shuttle Table

Modular Workbench

Masterline Series Laser

BEST QUALITY, High accuracy and productivity without compromises on the whole thickness range thanks to the Best inte gration of all machine components.

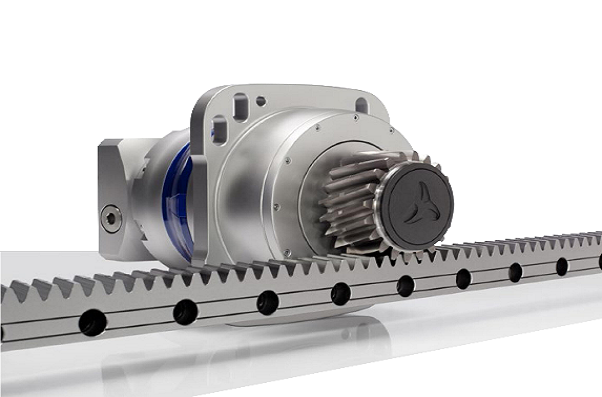

Rexroth Linear Guide Drive System

The beam is mounted on a pair of precision REXROTH linear guide rails and precision manufacturing have created the highest quality linear systems available today.

Axes Motionis Achieved By Rack

Axes motionis achieved by ALPHA rack & pinion design. there are not any intermediate load transmitting elements between the motor and the pinion which otherwise could cause precision losses.

Automatic Cleaning Nozzles

After a predefined number of contours, the nozzle automatically performs self-cleaning, without need for the intervention of an operator.

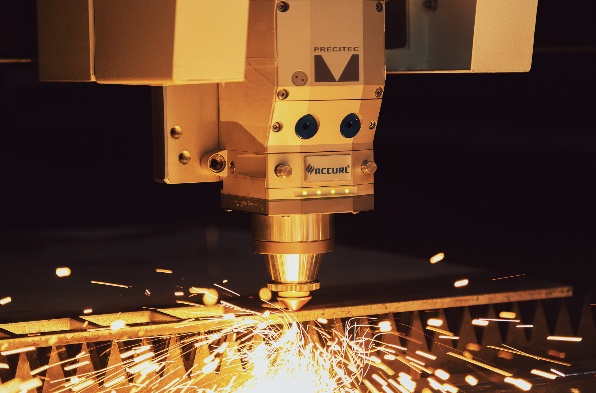

Precitec Cutting Head

NEW ProCutter 2.0 generation, the highest cutting speeds can be achieved that were previously unthinkable.

Servo Motors & Drives System

The MasterLINE is equipped with cutting edge Germany designed with High-speed EtherCATservo motors and drives from BECKHOFF.

Rack And Pinion Motion System

ACCURL® Laser uses the best German racks and pinions from ALPHA. High precision two-way, hardened helical racks with low running clearance make it possible to achieve very high acceleration and speeds synchronized 180 m/min.

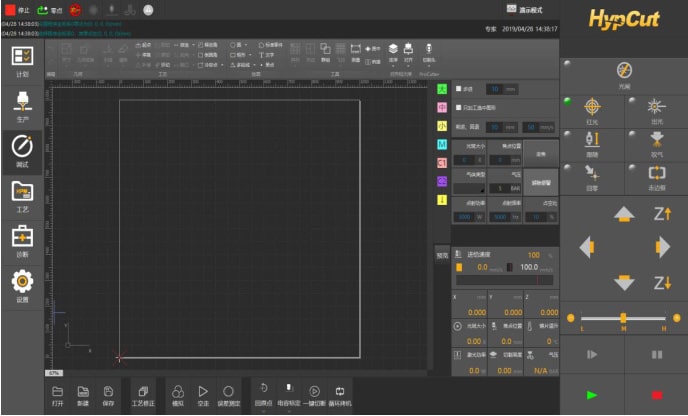

ACCURL FS-8000 Laser Cutting CNC Controller

FSCUT8000 is EtherCAT bus system designed for ultra high power fiber laser above 10KW, featured by out of box service, easy to install and adjust, full solution functions. It supports customization, automation and informatization solutions, is the leading edge EtherCAT laser cutting control system on the market.

Advantage:

- User friendly and touch optimized.

- Easy and efficient operation.

- Fly-cut option for significantly shorter cutting times.

- Nesting CAD/CAM software on board.

- Intuitive, step-by-step assistance for machine operators.

- Quick height adjustment for a very high and constant cutting quality.

- Integrated monitoring of peripheral units like laser sources and sensors.

- Support direct production of DXF & G code;support fast process of LXDS & NRP file generated by iCut.

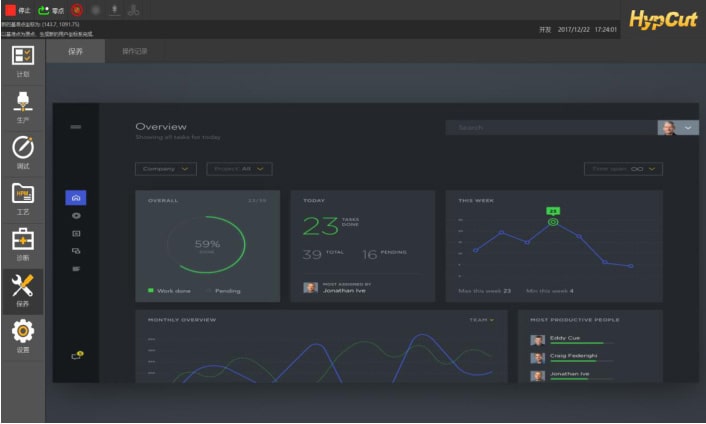

HypCut Numerical Control

The machine automation by Hypcut encompasses:drive technology,control systems,HMI, machine vision as well as seamless integration in TwinCAT Analytics based digital solutions for Industry 4.0.

HypCut Program Management

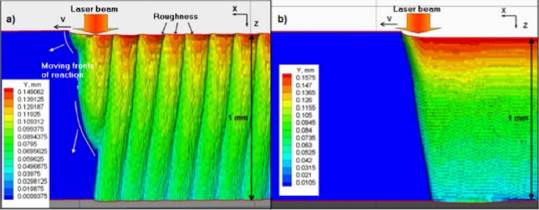

Multiple piercing solutions for metal sheet of different thickness; piercing slags removal; vibration suppression; close-loop gas control; seperate layer technique for large, medium and small contour cutting, all to expand your machine production capability.

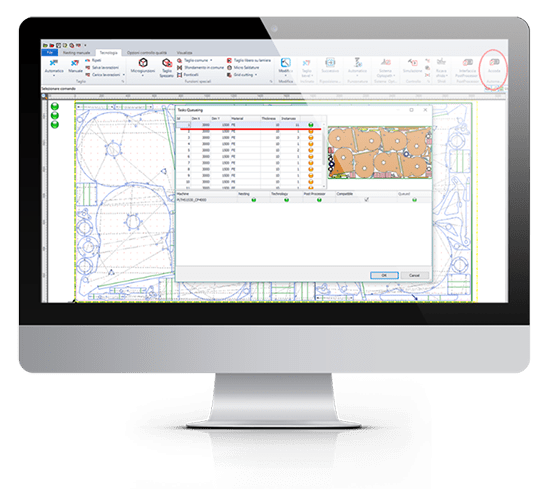

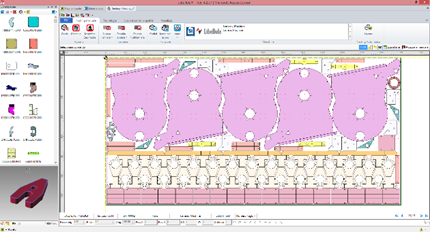

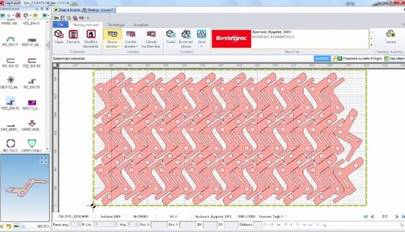

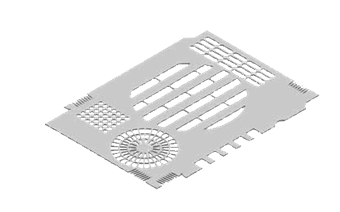

CAD/CAM Software Nesting. Libellula.cut

Thanks toits integrated CAD and the exclusive One-Click technology, Libellula.CUT creates or imports in a moment the geometric details from any other platform of drawing, automatically optimizing profi les and arranging them in an optimum manner fo subsequent processing.

A winning formula:

+ Automation + Integration + Effi ciency + Productivity

– Learning times and programming = Libellula.CUT

The best of the technological research of Libellula in a powerful and intelligent application, which reduces the processing time.

In Libellula.CUT, the software engineers and analysts have concentrated the

best of Libellula technological know-how in theme of sheet cutting:

- Fast and intuitive learning

- Full automation available in every step of the programming process

- Ability to manage all the cutting machines with the same system

Optional order Module

- Optimized information for the company with “Total Integration” additional Libellula modules

- Order Management with the option mod.ORDER module

- Warehouse management and reusable remnant with the mod.STORAGE option

- Optimization of cutting path and management for specific cutting technologies

- Reduction in the number of piercings

- Quality assurance of the machined parts

- Optimization of nesting with the [ISA] system and less scrap

- Optimized generation of nesting on uneven scraps

- Management of FMS lines and / or of the manual operations:

- Reduction of the cutting number of diff erent nesting

- Automatic Skeleton cutting

- Systems management of loading / unloading and sorting systems

Precitec® laser Cutting Head

The Precitec offers high-quality tailor-made solutions for all requirements and machine concepts in 2D laser cutting and has gained world wide recognition as the market leader in cutting optics, distance sensor technology,and process monitoring.

Cutting Head BLT 6 Series

The BLT421 cutting head comes with a revolutionary compact design and offers unmatched stable and precise operation. Achieve high-cutting edge quality, reduce service costs and downtime with the new laser cutting head from BOCI.

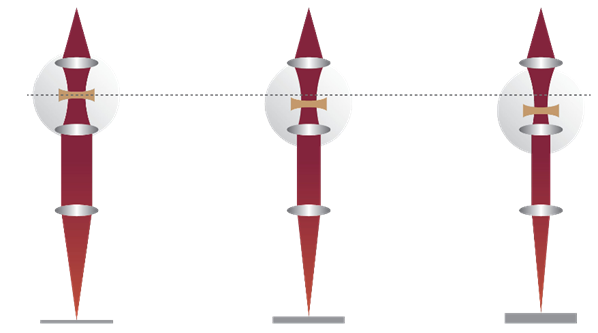

Precitec ® Zoom 2.0 Cutting Head

- Motorized focus position adjustment

- Zoom optics for automatic adjustment of the focus diamete

- Drift-free, fast-reacting distance measurement

- Permanent protective window monitoring

- completely dustproof beam path with protective windows

- automated piercing with PierceTec

- water cooling of the sheet metal with CoolTec

- LED operating status display

- Pressure monitoring in the nozzle area (gas cutting) and in the head

Laser Cutting In The Medium Power Range

Cutting Head Procutter Zoom 2.0

Cutting head with automatic laser beam adjustment, modified according to material thickness and set cutting speed.

Multitasking To The Extreme

Laser Cutting In The Medium Power Range

Loader & Unloader Brg System 2.0

- Fast processing of the order, since the automatic loading and unloading reduces the preparation times.

- Considerably greater use of machinery with only a slight increase in investment.

- Access to the production of parts with little manual work.

Material Screening And Loading System Smart-tower

Automatic Loading & Unloading System Smart-lifter

Freedom Of Choice, without Complications.

ACCURL® In order to meet our customers’ requests, we have created three suites of options to better fitthe different production needs: thin or thick metal sheets working and intensive productions.

Optimal cutting parameters are set in fully automatic manner according to material and thickness.

MasterLINE

CO2 or fiber: take your pick!

Fiber Laser Resonator IPG

- Direct control of all the fiber laser functions

- Synchronized control of the laser source

- Overall power control

- High speed perforation

- Edge machining function

- Cutting data library

- High speed fiber laser cutting

Fiber Laser Resonator IPG

The Laser | 2d Cutting Line