ACCURL

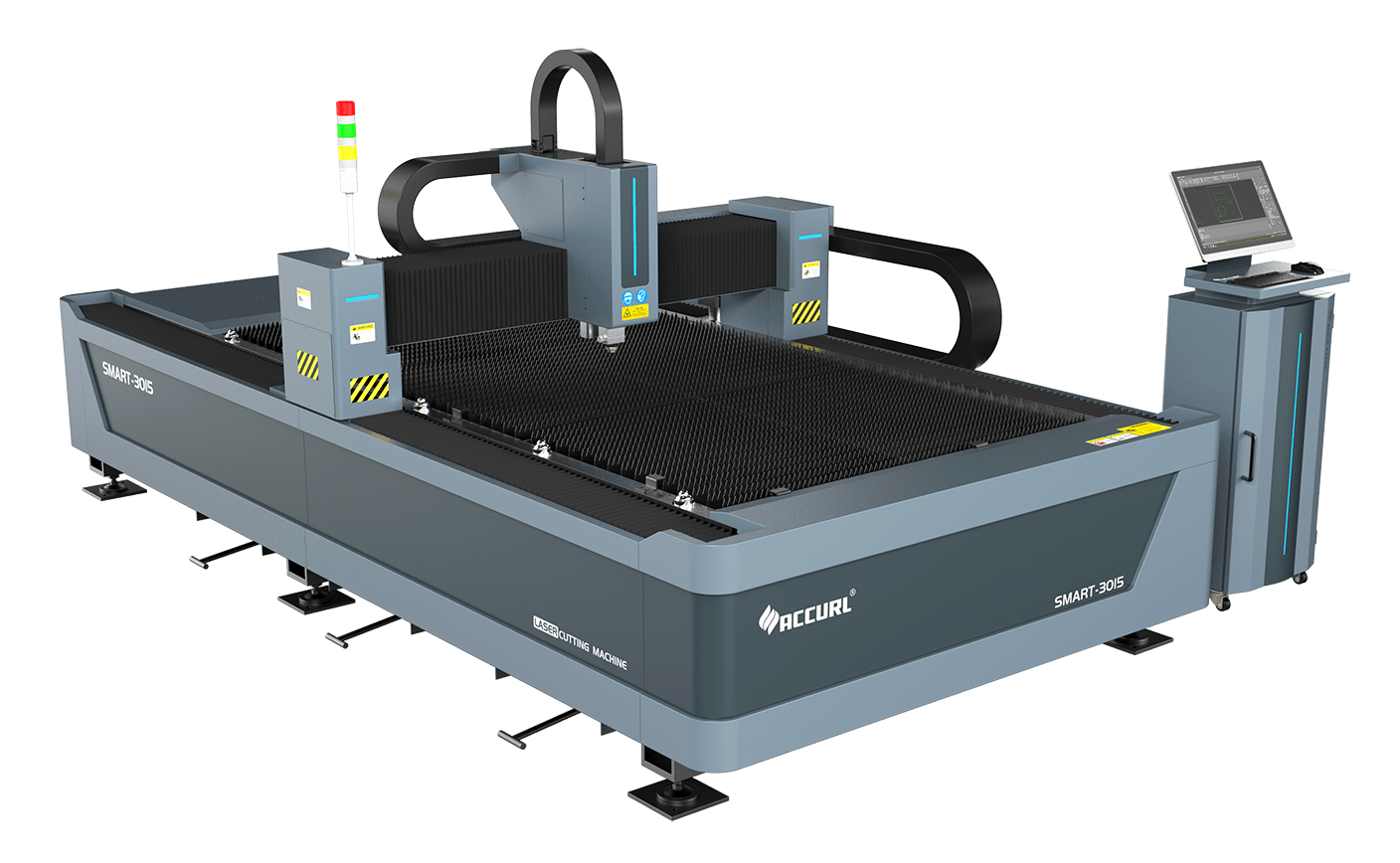

Smart 1Kw 1.5Kw 2Kw 3Kw Laser Cutter Machine

ACCURL

Smart 1Kw 1.5Kw 2Kw 3Kw Laser Cutter

Smart 1Kw 1.5Kw 2Kw 3Kw Fiber Laser Cutter

Includes Following Features And Configuration

Flexible

Reliable

Profitabie

User Friendly

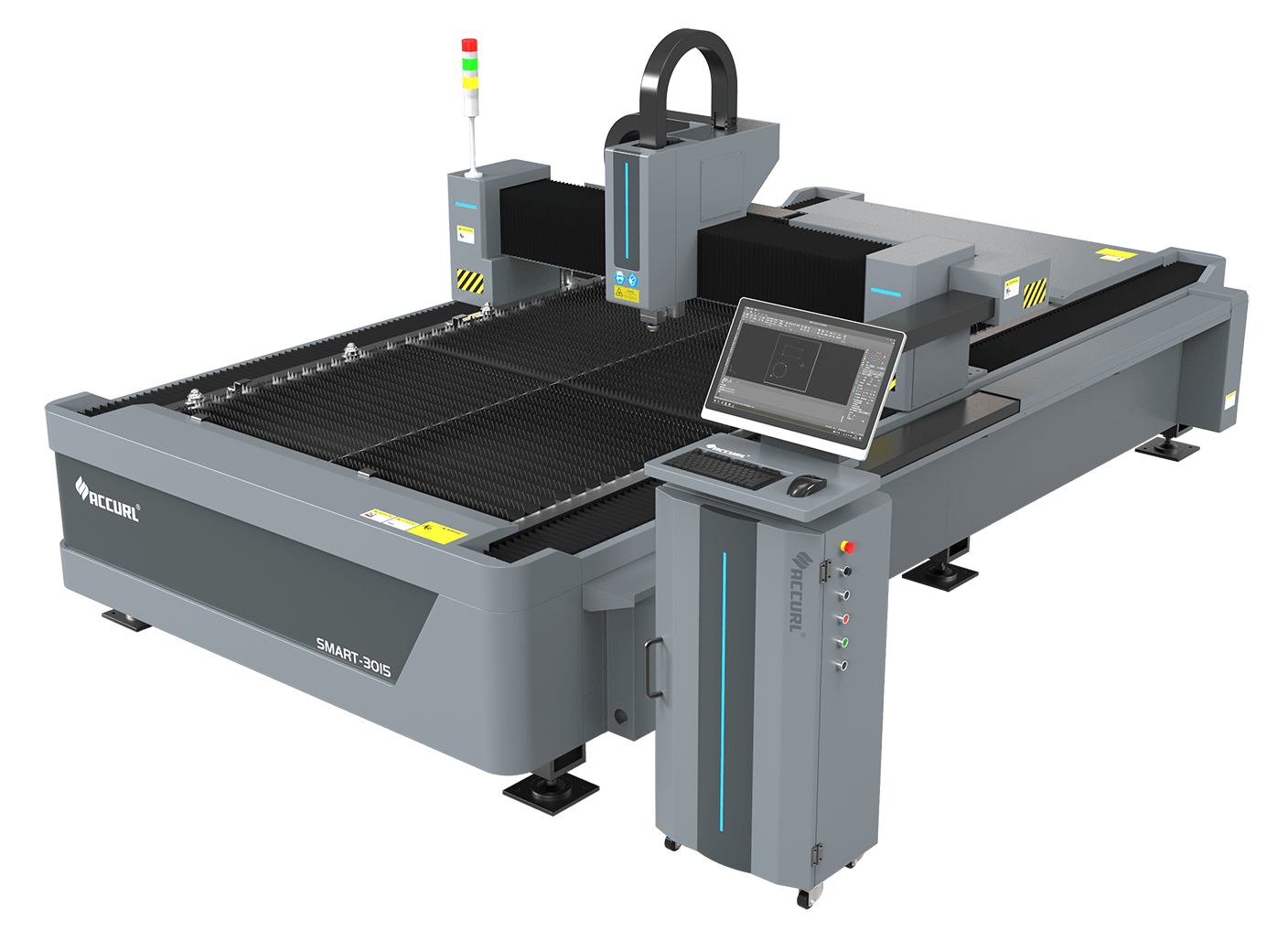

Standard included

- CYPCUT® CNC 17” SCREEN FSCUT2000 CNC Control System

- YASKAWA ® Highly dynamic EtherCAT servo drive

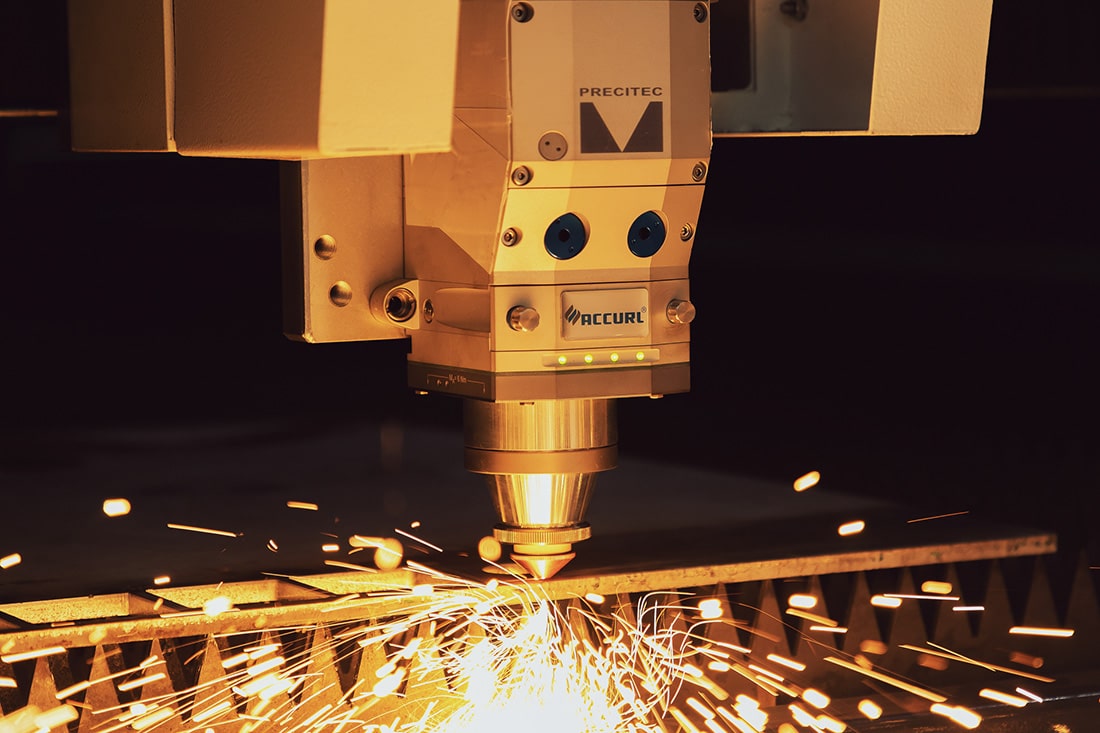

- RAYTOOLS ® Cutting head Auto Focus (Switzerland)

- ACCURL® Dynamic System 4.0: 1.2G Acceleration

- ACCURL® Fast piercing 2.0: Ultrafast perforation

- Automatic table exchanger 3015(Optional 4020 / 6020)

- Graphite Anti-burn Technology

- Smoke extraction Fan system

- fiber laser resonator IPG 1000w 1500w 2000w 3000w

- Smoke extraction system (TODC-4L/4500m³/h).

- Class IV safety system and CE marking

- Fully automatic voltage regulator System

- CYPCUT ®Embedded PCs: Industrial PCs with directly integrated I/O level

Technical

Advantage:

- User friendly FSCUT 2000 CNC Control System and Servo Package

- Advanced Swiss RayTools AG cutting head (with air cross blast).

- Fully enclosed and cabined to ensure e maximum operator protection.

- Effective high to low pressure gas exchange system.

- Capacitive Sensor, high pressure cutting head.

- Automatic mechanized Nesting power output control function.

- Automatic mechanized Nesting power output control function.

- Automatic time and unit cost calculation function

- Network connection from external.

- Smoke extraction (included in series models).

- Collection of work pieces and trimmings.

- Dual proportional valve control system for different gas pressures and special system for high pressure cutting.

Unique features::

- Maximum simultaneous positioning speed: 120m/min.

- Acceleration speed: 17 m/ s2 (1.2G).

- Precision: ± 0.01 mm

- Energy efficiency: greatly reduced power consumption.

- IPG Resonator. Power output from YLR-1500K

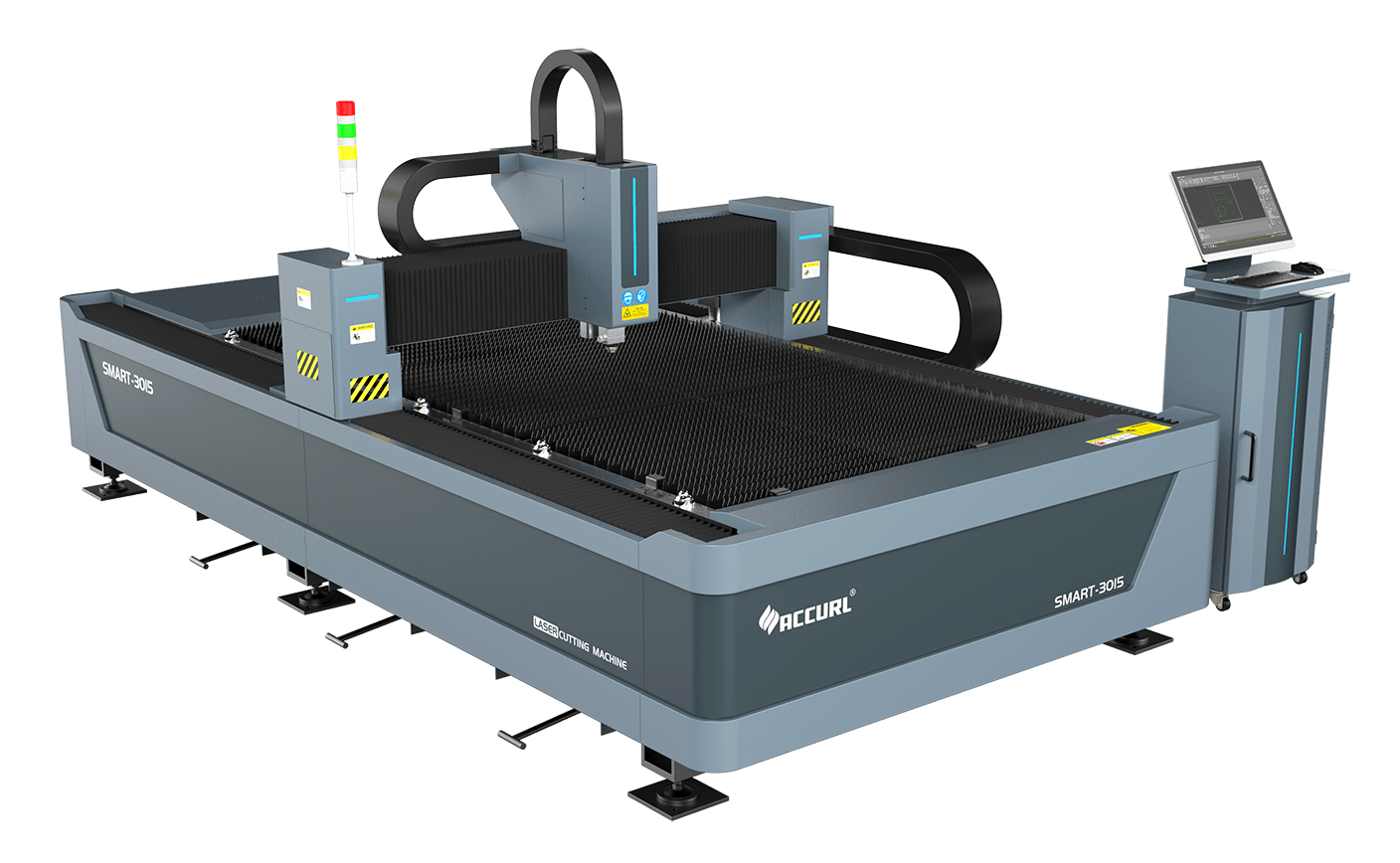

Mechanical Processes

Heat Treatment Processes

ACCURL press brake and laser cutting machine steel frames undergo annealing at over 600⁰ to relieve stress. and they are built to last years of heavy use without distortion.

Advantage:

- Very stiff and stable base frame

- Electric welding of high precision

- Usage of high-tech boring machines for extreme precision parts.

Finishing Machining

Advantage:

- Very stiff and stable base frame

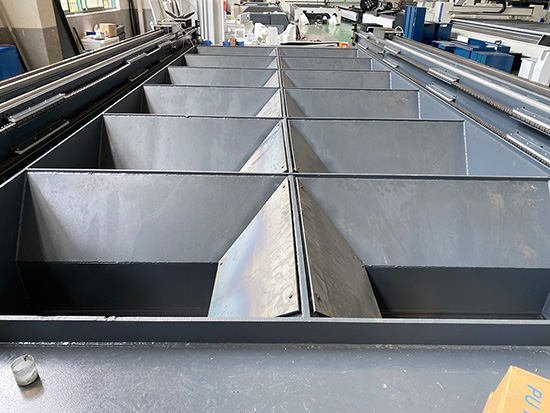

- Eight (8) zone & ducted exhaust system

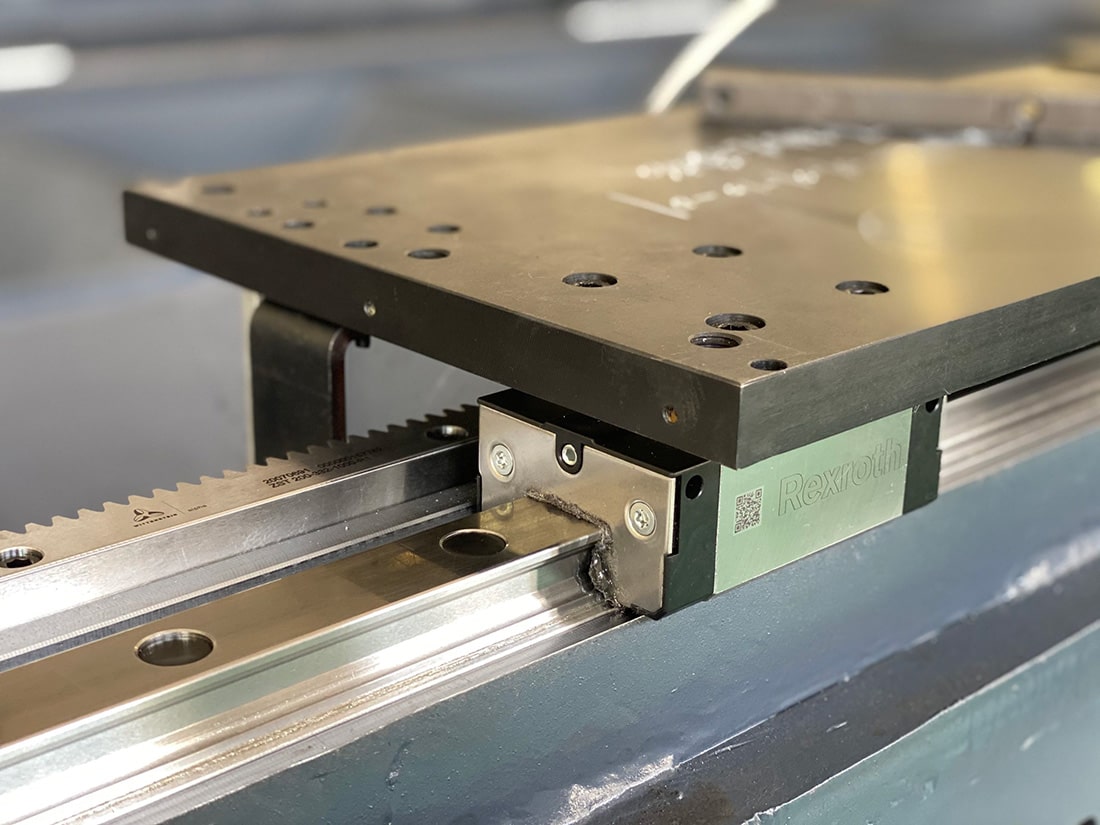

- Dual synchronized twin servo motor drive system

- Helical rack & slant pinion drive system enables very smooth Movements.

Framework

ACCURL® assemble their laser cutter to the strictest quality standards with nothing but world class components to ensure lasting quality at an attractive price.

A heavier frame means less vibration and better accuracy. the machine frames are reinforced to minimize twists and deformation while the robust frame of the machine is joined to the chassis by steel bars.

Smaller air flow from the dust collector

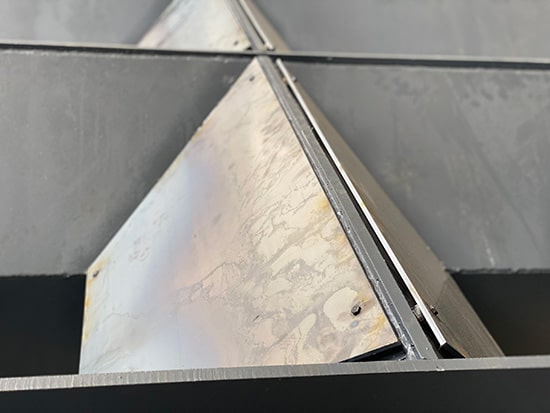

Covered & protected by 20mm thick graphite anti-burning

Why Accurl Laser Machine?

ACCURL® Based on machinery design technology optimized through strict structural analysis, ACCURL has been manufacturing ultralight and high-precision industrial high energy laser cutting machines. In addition, we provide total solution for sheet metal working that customer want such as bending, welding, deburring, and loading automation.

Experience

- 33 years of experience and more than 12,000 installed machines.

- An expert R&D team committed to research the most competitive technology for our customers.

More Varied Solutions for Cutting

- Sustainability and social responsibility are characteristics of modern companies and add to competitiveness.

- Comprehensive range of basic tools in stock and modified solutions according to customer needs.

ACCURL High Quality Equipment

- The critical parts of the Accurl laser machine are manufactured in Germany.

- We rely on our quality and therefore give our laser cutting machine a 3-year warranty.

- The IPG Fiber resonator. Power from 1Kw To 30kW.

After-Sales Service

- Original ACCURL spare parts to guarantee full performance and prolonged durability.

- Wide range of consultation services on machine operation, programming and maintenance.

Aluminium Gantry Structure

ACCURL® high tech aluminum crossbeam is cast in a specially manufactured 10-tonne steel mould. This allows better rigidity at 50% of the weight of traditional iron gantries, allowing higher acceleration with reduced inertia.

ACCURL Using German imported laser interferometer measurement and adjusting the linear operation precision of the machine, to ensure the accuracy of mechanical structure reaches 0.01mm.

Drive System

The beam is mounted on a pair of precision REXROTH linear guide rails & with advanced German ALPHA engineering and precision manufacturing have created the highest quality linear systems available today.

ACCURL® Laser uses the best German racks and pinions from YYC. High precision two-way, hardened helical racks with low running clearance make it possible to achieve very high acceleration and speeds synchronized 170 m/min.

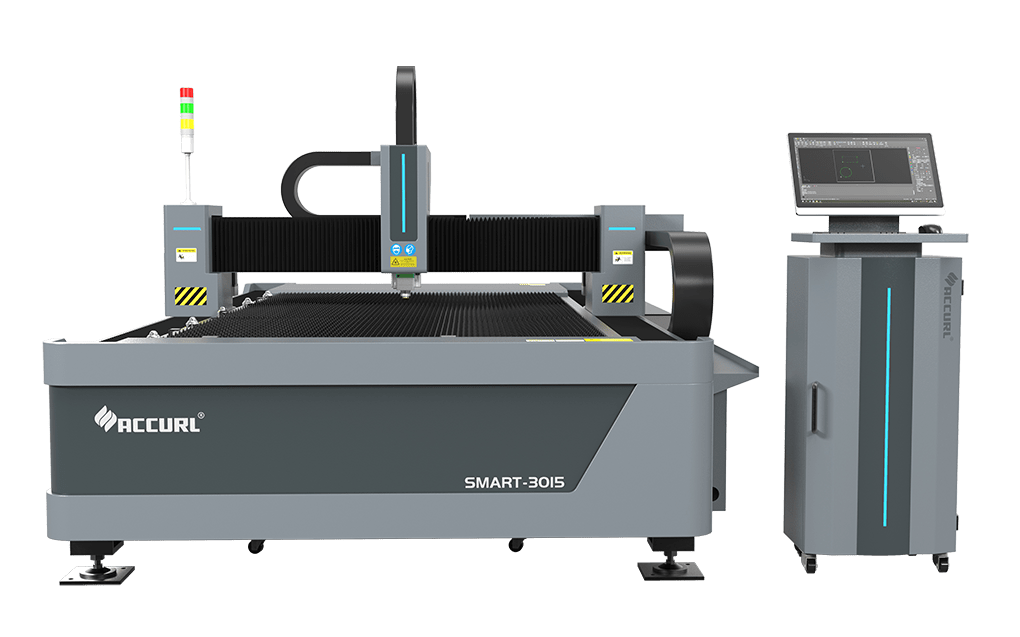

CNC Control System

Main functions:

Support the AI, DXF, PLT, Gerber, and ect. Graphics data format, accept raw Mater Cam, Type3, Wen Tai software into international standard G code.

CYPCUT CNC System Features:

- 22” high resolution color TFT(Optional touch screen control)

- Highly dynamic servo drive technology

- Integrated retention brake control.

- Automatic adaptation of parameters.

- Adjustable error reaction.

- Motor feedback for absolute position registration.

- The same set of software support pipe cutting and flat cutting, the same programming; Support the intersecting line cutting.

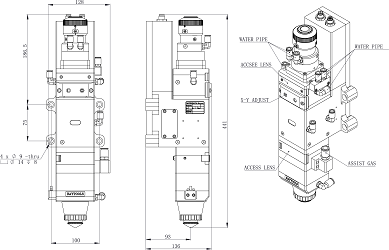

Cutting Head Raytools

- 35mm clear aperture, effectively reducing stray light interference, guarantee cutting quality and service life;

- Motorized adjustment of lens position

- Anticollision system included

- Contains adjust box EG 8030, focal lens 200mm, glass protection, 3 nozzles.

- Cutting head contains collimator at 90º focal 100mm

- With a variety of optical interfaces, can be adapted with a variety of fiber lasers.

- Compact design

- Motorized protection windows

- Auto focus ranges +10~-12mm, accuracy is 0.05mm

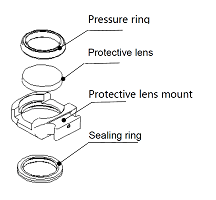

- Drawer-type of lens mount, quick and easy access to the cover glass

- Automatic adjustment of the focus and depth of the laser beam by "MZ - collimator module.