Description

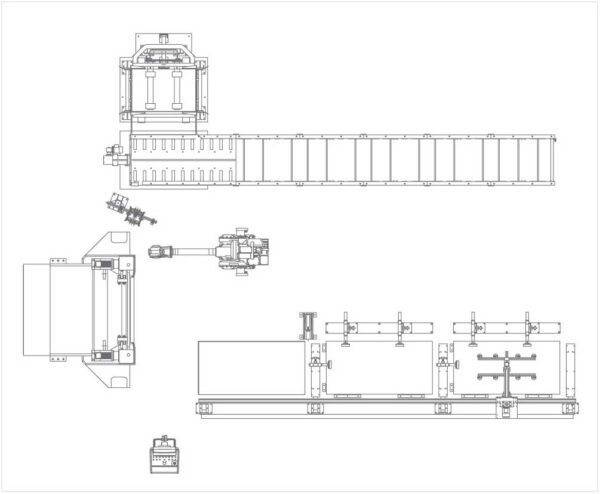

The protagonist of automation Robotic Bending Solutions:

ACCURL press brakes can be used in a robotic cell, either completely robotic, or when a robot and an operator can alternatively use the CNC machines.

Thanks to the ACCURL Bending robot and automatic loading/unloading devices, the cell with two levels of automation – process and operation – is a reliable solution for unattended production, even at night.

All risks associated with part handling during bending are faced by the robot and not by the operator.

Connections:

The ACCURL Robotic bending cell system can be equipped with different types of loading and unloading connections, depending on the client’s production requirements.

- Loader from a precentred pack.

- Loader from a Cartesian feeder in masked time.

- Cartesian feeder with controlled axes.

- Feeder/unloader for connection in line with ACCURL systems.

- Unloader.

- Carousel unloader.

- Roller-surface unloader for pallets.

- Roller-surface unloader for pallets and crates.

- Un-intrusive machine integration with sensors to back gauge fingers and bending beam which follow the programmed sequence of the Accurl press brake.