How the IRIS PLUS IRIS PLUS bending angle measurement systems work for Stainless steel electric cabinet??

ACCURL 7-Axis CNC Press Brake with Automatic bending angle measurement System! ACCURL represents a synthesis between technological innovation, & attention to detail/design. Add the best components in the world, and Accurl offers customers the foremost solution with an impressive Quality & Price ratio.

ACCURL® New Hybrid Servo CNC Press Brake combines power and precision into a European design. Using a combination of electric and servo drive systems, these hybrid machines are highly efficient, impressively quiet, and utilize the latest in Accurl Motion Technologies. And the Premium is the ultimate in creating complex parts.

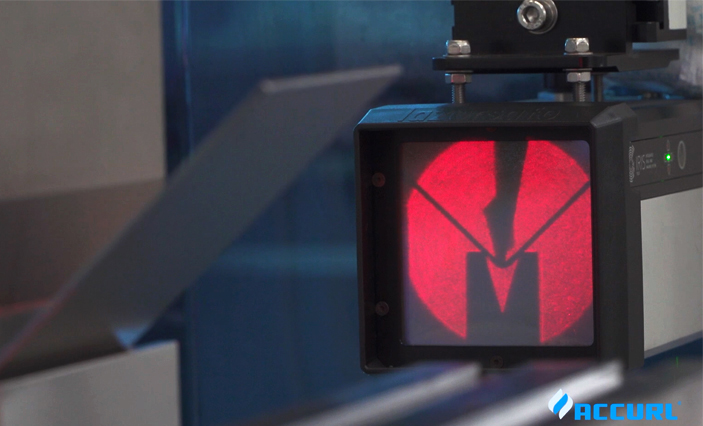

ACCURL’s CNC Press Brake with IRIS Plus comprises a laser transmitter and receiver set mounted to the upper beam of the press brake. It includes a high-speed digital camera and image data processing system contained within the receiver unit.

- BendVision for angle measurement:

- Automatic Angle Measurement Control:

- Active Angle Control

- Dynamic Angle Control

Automatic bending angle measurement and automatic correction of the bending angle Active Angle control is a highly accurate angle control process that calculates spring back for each individual bend, then controls the bend depth with Live Angle Bending to achieve the correct angle.

Features for CNC Press Brake:

- DELEM® DA66T 2D graphical/3D visualization CNC Control Unit

- ACCURL® BGA-5 for X=800mm X,R,Z1,Z2 with Delta X2 +/- 125mm

- Germany HOERBIGER Hydraulic System

- ACCURL® European Quick Release Clamping

- ACCURL® Press Brake Productivity Cabinet for Tools

- ACCURL® Crowning Table with Die Rail (Groove 13.5mm width, 22 mm Height)

- CE Norms: OEM Embedded Lazersafe Systems LZS-2 Block Laser

- SIEMENS Foot Switch (Level 4 of safety)

- ACCURL® Hybrid Servo ECO Function (Reduction of energy consumption up to 35%)

- WILA® New Standard Pro Punch Clamping with With Smart Tool Locator® (STL)

- LAZERSAFE® Bending Angle Measurement System IRIS PLUS

- Sliding Front Arms with full length linear guide

- Industry 4.0 of Productivity Monitor (software version V3.5.3)

- Safety covers for inside and outside main cylinder with LED Floodlight

- CE Norms with Two sides door-type safety guard and rear safety guard with rear door

ACCURL® BGA-5 CNC BACKGAUGE SYSTEM:

ACCURL® press brake is provided are equipped with BGA-5 CNC backgauge constituted by a solid structure in order to assure the best repetitiveness and high precision in axes positioning.

ACCURL®BGA-5 for CNC BackGauge:

- Stroke X = 500 mm

- Stroke X2= 100 mm

- Max. Speed X = 450 mm/s

- Max. Speed R = 250 mm/s

- Max. Speed Z1-Z2 = 600 mm/s

Advantage:

- X ,R-Axis with HIWIN linear guide and Ball Screw.

- Z1,Z2-axis with HIWIN linear guide and YCC Rack.

- Less noise, greater durability and greater precision

- Unprecedented positioning repeatability of ±0.1 (optional ±0.05).

- The backstop with the X2-axis for bending part of staggered resting points.

- To reach maximum versatility you can automate both backstops with X1-X2 axes, reaching an angle of 80° on oblique bends.

- High-speed movement on all axes ensures that the gauge fingers are positioned as quickly as the operator positions the part