Description

The ePrAX Hybrid Servo System- improving energy efficiency of up to 73 % compared to conventional hydraulic systems is an innovative servo drive for 8AxisCNC press brakes, and thanks to the brushless servo motor, we can precisely control the movement of the slider ram using a minimum amount of oil and energy.

The3.2meter x 220 Ton New ACCURL 8-Axis Press Brake Europro is Accurl’s general level press brake with market oriented execution. These high quality European built press brakes feature 2d multi touch graphical control. Accurl CNC press brakes offer the best price to performance value for your fabrication needs.

The CNC press brake Body and upper beam made of steel constructions, has been designed according minimum stretch and optimum resistance criteria, as the manufacture of precision CNC machining center is a single operation.

Click to download Accurl press brake Europro CNC 2D control brochure

STANDARD EQUIPMENT

- DELEM DA-66T CNC control unit with 2D graphics

- 6+1 axis CNC

- Y1, Y2 precision ram positioning

- Standard BGA-4 for X, R, Z1, Z2-axis (X=800mm, R=200mm)

- DELEM CAD/CAM Profile-T3D Expert 3D Offline Software

- ACCURL PRO CNC motorized wave crowning

- Large trio of value

- Large open height

- Large stroke

- Large throat depth

- HOERBIGER hydraulic valve block, pump and valves

- High Siemens efficiency motor– class IE3

- Hybrid ECO Function for energy-saving drive

- Rear cover: Safety barriers (Category IV)

- Sheet metal frontal supports

- Front and rear lighting

- Industry 4.0 of Productivity Monitor (software version V3.5.3)

- CE Norms: OEM Embedded Lazersafe Systems PCSS A0 + LZS-2 Block Laser (Category IV)

DELEM /ESA /CYBELEC CNC CONTROL UNIT

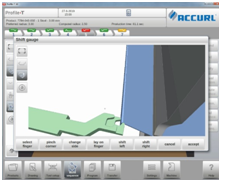

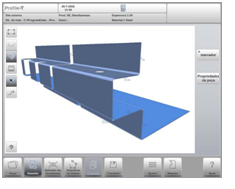

ACCURL® has chosen the very powerful new generation DELEM DA66T/DA69T also can optional ESA S640 2D graphical /ESA S650W /ESA S660W 3D graphical CNC Control and CYBELEC CybTouch 12 PS / CybTouch 15 PS 2D and CYBELEC VisiTouch 19 MX 3D offers an higher level of efficiency in programming and control of CNC press brakes. The DELEM winning MADE in Netherlands design and the high quality of all the construction details, guarantee prestigious performances and long product life.

The application of Multi Touch technology reduces the number of keyboard- and button actions to an absolute minimum. The innovative Smart Draft, Design/Bending Multitasking, Step Previewer and Combined Icons features allow the operator a straightforward, intuitive control of the entire production cycle.

- 17” high resolution color TFT(touch screen control)

- Design and Bending Sequence Calculation in Multitasking Mode

- Standard 2D/3D visualization

- Automatic or manual bending

- Automatic double bends solution

- Execution of generated 2D-programs

- Editable graphical tool database

- Editable material database

- Automatic/ Programmable retraction

- False bend solution

- Exporting of computed flat patterns as DXF ,3D STEP, IGES files(Profile-T-3D)

- Real time bend sequence calculation

- Multi-language support

- 3D Simulation with automatic best bend sequence identification with collision detection.

Click to download DELEM DA66T DA69T CNC control brochure

OPTIONAL FOR WILA® NEW STANDARD CLAMPING SYSTEM

The Wila’s ‘New Standard’ Tooling System has become market leader for precision, quality and flexibility for the Accurl press brake. the WILA’s state-of-the-art clamp systems offer optional for the ultimate efficiently changing tools with Smart Tool Locator® (STL)* have made the changeover process easier and safer. and Premium is available as an option.

Advantage:

- Hydraulic power source

- Quick clamping for Europe style tooling

- Simple push-button loading

- Max. load head/shoulders 180 t/m

Optional forSmart Tool Locator® (STL)

Increase your press brake productivity

- The Smart Tool Locator (STL) further increases your press brake productivity. The system indicates by means of built-in LED’s the right clamping position of your tooling during tool set up and indicates the active tool location in production mode.

- The Smart Tool Locator offers significant benefits in speed, precision and flexibility.

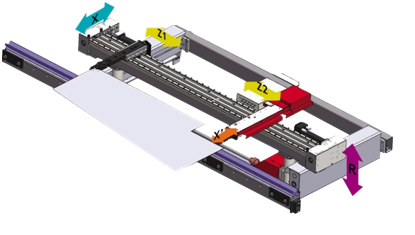

BGA Series BACK GAUGE FOR CNC PRESS BRAKE

ACCURL® press brae are provided are equipped with BGA-2-6-axis CNC backgauge constituted by a solid structure in order to assure the best repetitiveness and high precision in axes positioning

ACCURL 2-Axis CNC BackGaugeBGA-2 for X ,R-Axis

ACCURL 4-Axis CNC BackGaugeBGA-4 for X ,R,Z1,Z2-Axis

ACCURL 5-Axis CNC BackGaugeBGA-5 for X ,R, Delta X ,Z1,Z2-Axis

ACCURL 6-Axis CNC BackGaugeBGA-6 for X1 X2, R1 R2, Z1 Z2-Axis

Max. Speed X = 450 mm/s

Stroke R = 200 mm

Max. Speed Z = 550 mm/s

Advantage:

- X ,R-Axis with HIWIN linear guide and Ball Screw.

- CNC(Manual) Z1,Z2-axis with HIWIN linear guide.

- Unprecedented positioning repeatability of ±0.05 (optional ±0.01).

- To reach maximum versatility you can automate both backstops with X1-X2 axes, reaching an angle of 80° on oblique bends.

**ACCURL offers consumables, parts and Hypertherm materials at very competitive prices.

*** Note: As products are constantly updated, please contact us for latest specifications. ***