Description

Nothing makes me happier than seeing a customer smile from ear to ear after seeing how accurate their forming process will now be with the addition of their ACCURL CNC Press Brake. Congratulations to our newest family member, who is located In Nebraska.

Their GeniusPro 4-Axis Press brake is rated at 160 tons and is equipped with a CNC programmable DA58T control, ECO energy saving drive, CNC crowning, DSP laser safety, sectionalized upper/lower tooling with quick clamps, and many other incredible features which are included standard on our GeniusPro model!

You cannot pursue today’s work with yesterday’s machine. Contact us now to learn how to get ahead of the industry!

Click to download Accurl press brake Europro CNC 2D control brochure

STANDARD EQUIPMENT

- DELEM DA-58T CNC control unit with 2D graphics

- ACCURL 4+1 axis CNC Press Brake

- Y1, Y2 precision ram positioning

- Standard BGA-2 for X, R and Manual Z1 ,Z2-axis ( X=600mm,R=200mm)

- ACCURL PRO CNC motorized wave crowning

- HOERBIGER hydraulic valve block, pump and valves

- High Siemens efficiency motor– class IE3

- Hybrid ServoECO Function for energy-saving drive

- Rear cover: Safety barriers (Category IV)

- Sheet metal frontal supports

- Front and rear lighting

- Industry 4.0 of Productivity Monitor (software version V3.5.3)

- CE Norms: OEM Embedded Lazersafe Systems PCSS A0 + LZS-2 Block Laser (Category IV)

DELEM DA58T 2D CONTROL CNC UNIT

The new generation DA-50T-series offers easiest CNC programming based on the Delem graphical touch screen user interface. And the DA-58T is a state of the art complete 2D graphical control solution for synchronized CNC press brakes

Its 15″ high resolution color TFT, with industrial grade multi touch screen technology, gives access to the proven Delem user-interface. It enables direct navigation between product programming and actual production. Functions are directly located where needed, offering optimized ergonomics throughout the entire application.

DA-58T features:

- 2D graphical touch screen programming

- 15″ high resolution color TFT

- Up to 4 axes (Y1,Y2 + 2 aux. axes)

- Crowning control

- Tool / material / product library

- Servo and frequency inverter control

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- USB memory stick interfacing

- Profile-58TL offline software

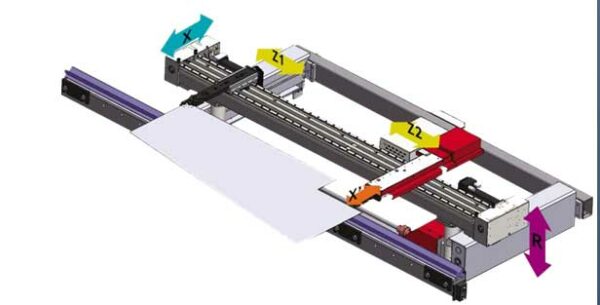

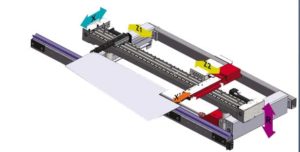

BGA Series BACK GAUGE FOR CNC PRESS BRAKE

ACCURL® press brake are provided are equipped with BGA-2-6-axis CNC backgauge constituted by a solid structure in order to assure the best repetitiveness and high precision in axes positioning

ACCURL 2-Axis CNC BackGaugeBGA-2 for X ,R-Axis

ACCURL 4-Axis CNC BackGaugeBGA-4 for X ,R,Z1,Z2-Axis

ACCURL 5-Axis CNC BackGaugeBGA-5 for X ,R, Delta X ,Z1,Z2-Axis

ACCURL 6-Axis CNC BackGaugeBGA-6 for X1 X2, R1 R2, Z1 Z2-Axis

Stroke X = 800 mm

Max. Speed X = 450 mm/s

Stroke R = 200 mm

Max. Speed Z = 550 mm/s

Advantage:

- X ,R-Axis with HIWIN linear guide and Ball Screw.

- CNC(Manual) Z1,Z2-axis with HIWIN linear guide.

- Unprecedented positioning repeatability of ±0.05 (optional ±0.01).

- To reach maximum versatility you can automate both backstops with X1-X2 axes, reaching an angle of 80° on oblique bends.

*** Note: As products are constantly updated, please contact us for latest specifications. ***