ACCURL

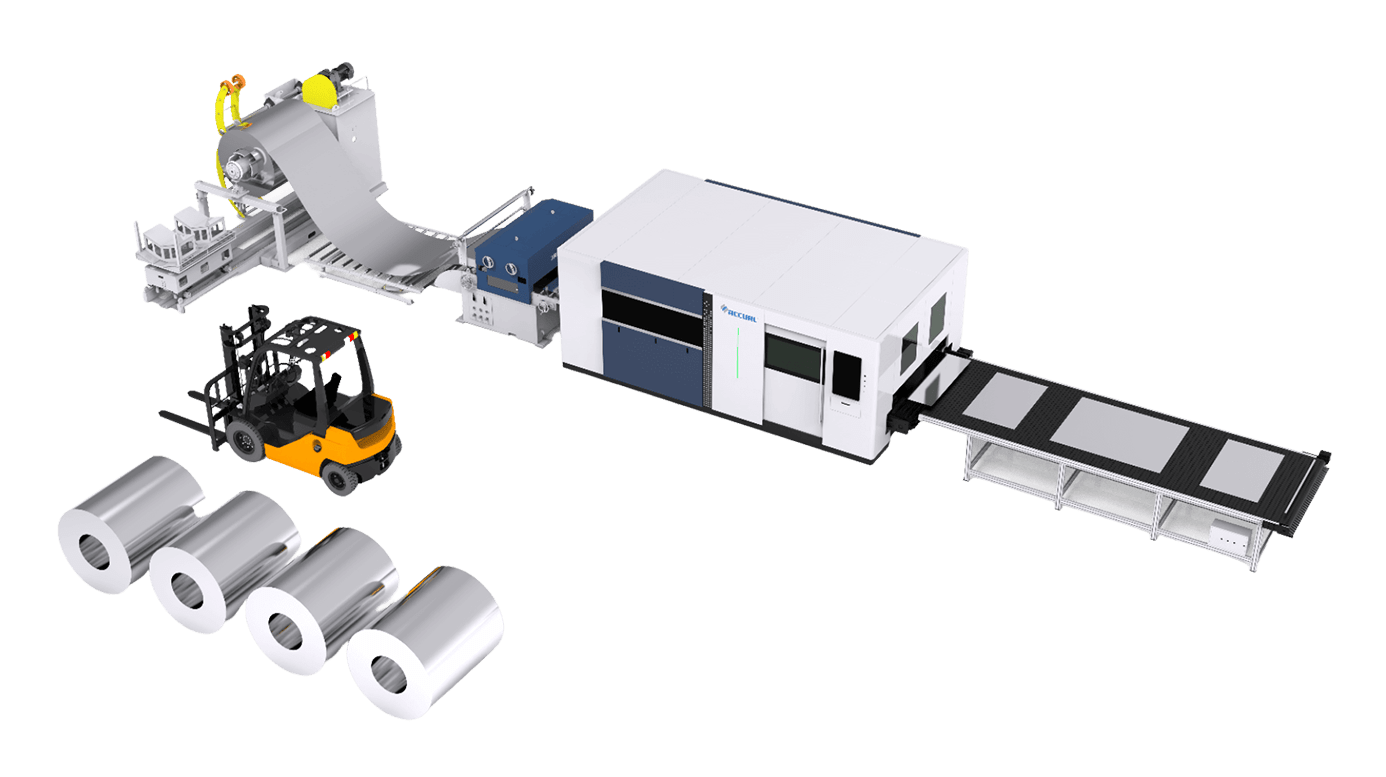

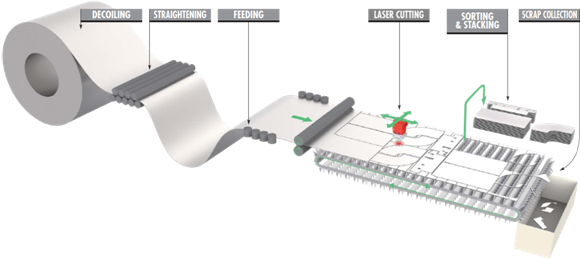

Coil and sheet fed laser cutting

LINECUT® Series

The automatic coil-fed and sheets fed laser cutting machine from laser cutting blanking line has the most versatile setup.It processes with the maximum simplicity strips up to 1550mm in width, and sheets up to 14 meters in length with a very compact layout.

Simplicity Meets STATE-OF-THE-ART Laser Cutting Technology

ACCURL® has developed a whole range of coil-fed (and sheet-fed) laser cutting systems and systems for sheet metal. The different solutions are available for different types of production, whether from steel coil or standard sheets, with fiber laser cutting or combined punching/laser systems.

Features of the Laser System:

- Working area 1500x3000mm

- Machinable material: from 0.5 to 2mm gauge, up to 800 ~1500mm in width

- Source by IPG Photonics

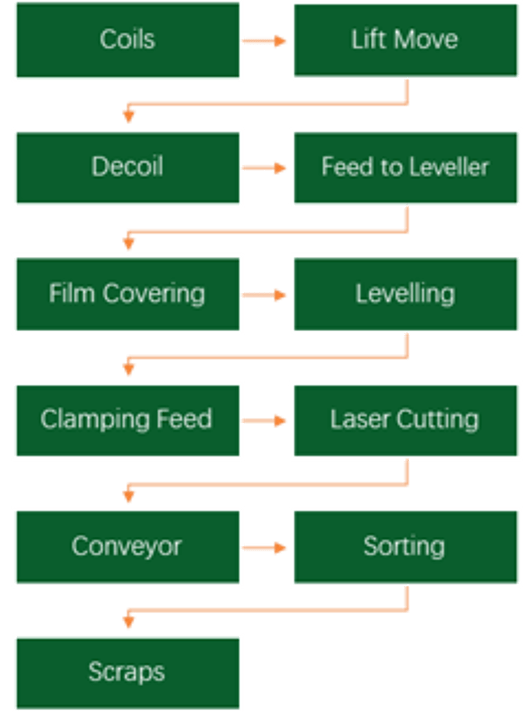

Elements making up the system are:

- 15000kg decoiler

- ACCURL feeder with Coil Car

- LINECUT-3015 fiber optic laser cutting system

- Fiber optic laser source from 1000W up to 4000W

- Chiller cooling system.

- Coil lines are customized to match specific material requirements.

- CypCut CAM programming/nesting software for processing coils of the same width as the product (100% material used).

Unique Manufacturing Process

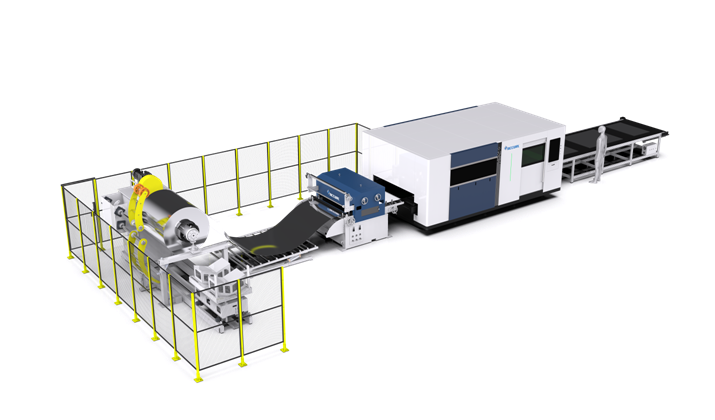

ACCURL has employed cutting-edge technologies to manufacture LINECUT-line automatic coil fed laser cutting system that are flexible and easy to use. By using fibre laser sources, production rate is fast and energy consumption low, while the integrated CNC system ensures very high precision.

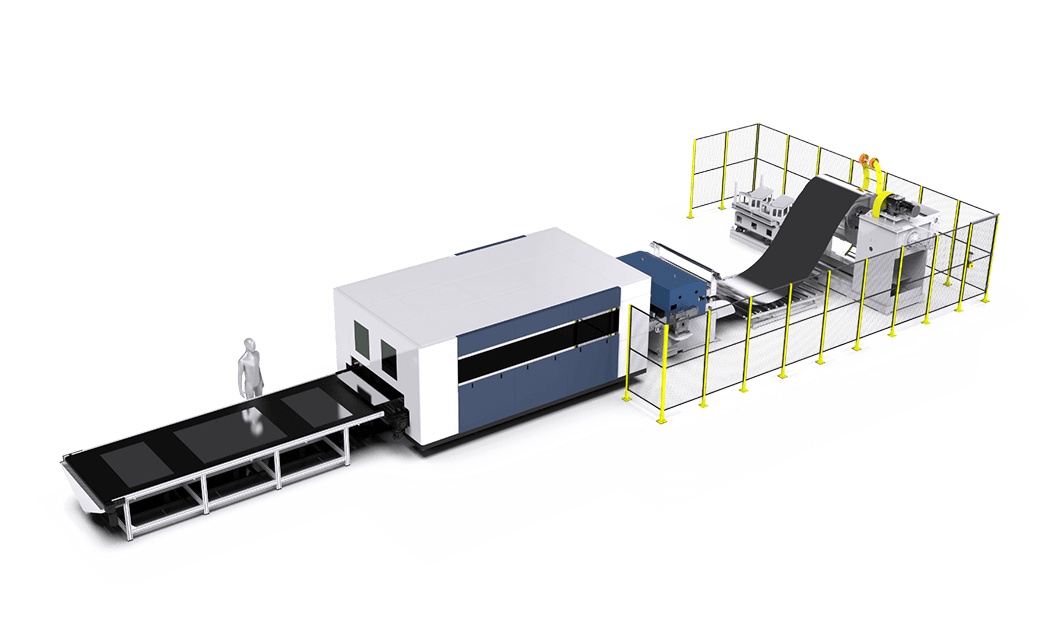

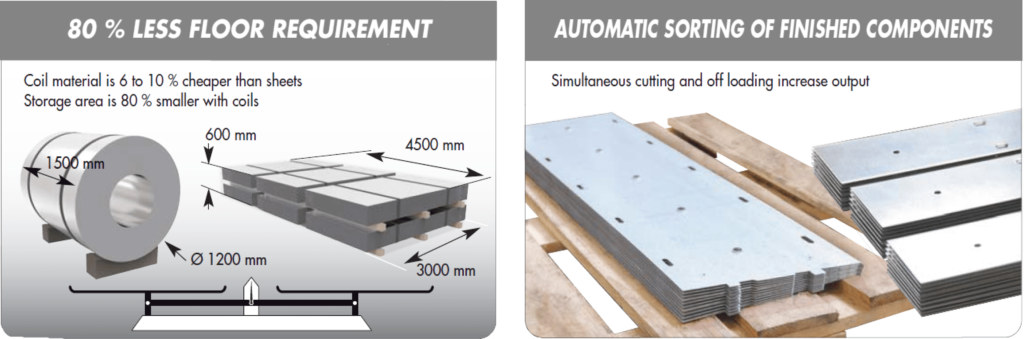

80 % Less Floor Reqeirement

The ACCURL LINECUT range includes in-line, automatic fibre laser cutting systems that are flexible and easy to use. and the LINECUT lines can be set up according to the characteristics of the materials to be machined and may also incorporate customized unloading systems.

Benefits:

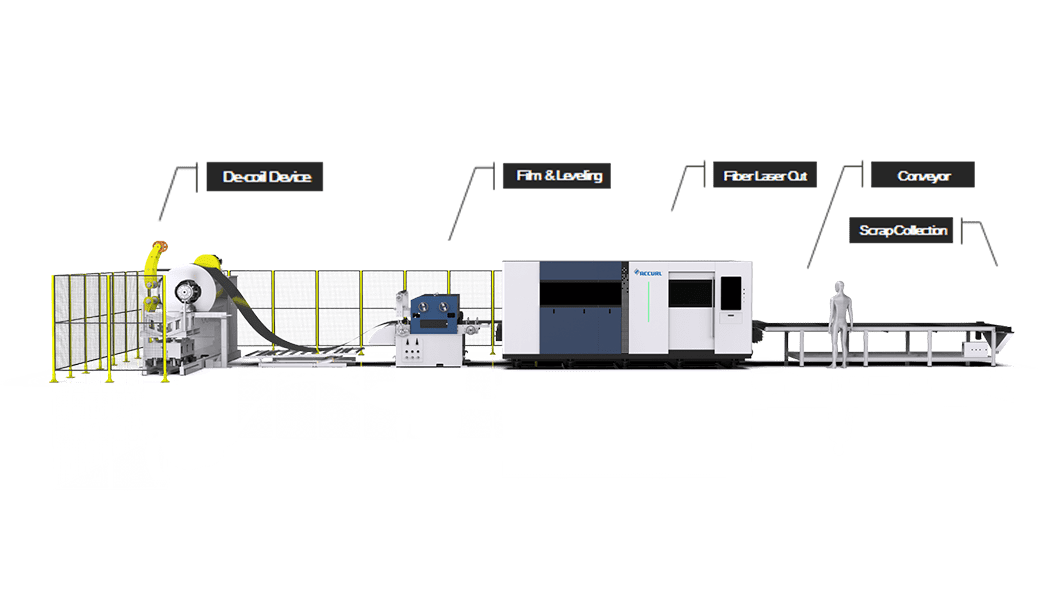

- The Operation of the ACCURL LINECUT coil-fed laser cutting lines is user friendly.the lines have a compact footprint and consist of the following elements:

- Decoiler

- Straightener

- Roller conveyor

- Feeder

- LINECUT laser cutter

- Unloading system

Coil Fed Laser Cutting System

Always looking for more efficient solutions towards his customers, ACCURL designed his new LINECUT concept combining the unmatched flexibility of laser cutting together with the performance of Accurl coil fed processes.

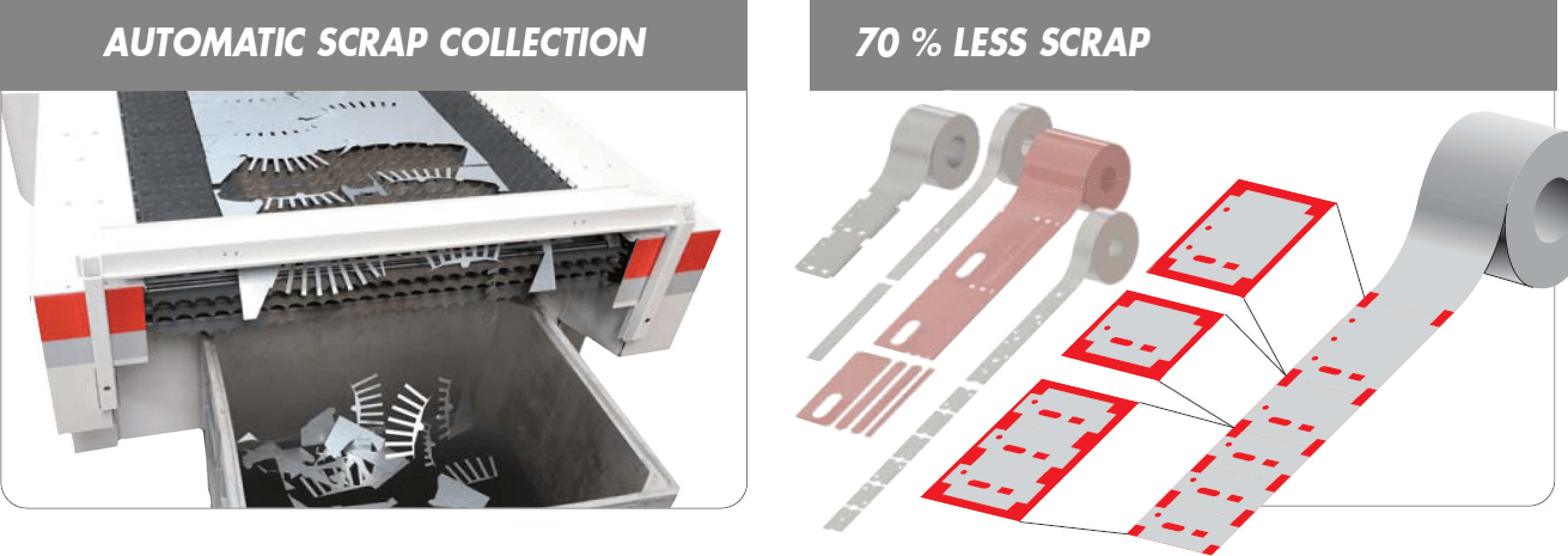

Coil Feeding Allows No Length Limit For Products

Fully automated process minimizing operator requirement and allowing continuous and unattented production.

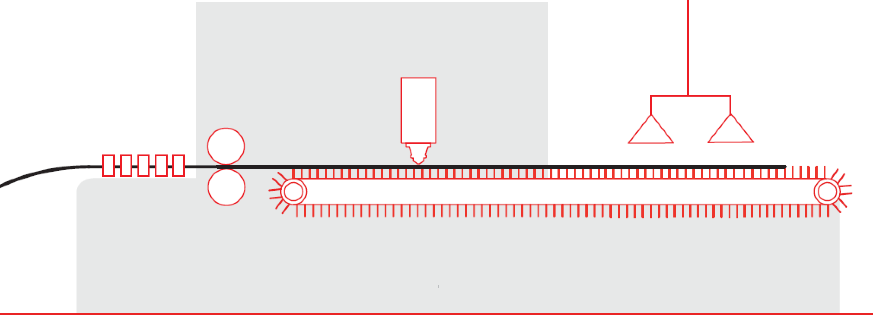

Slat Conveyor: Unique Continuous Mode For Linecut

To allow simultaneous cutting and part off loading,slats are simultaneously moving with the strip(conveyor design).

The accuracy of specific ACCURL construction and synchronisation allows to move accurately the parts to the pick up area in order to obtain quality blanks stacking, and avoid any scratches.

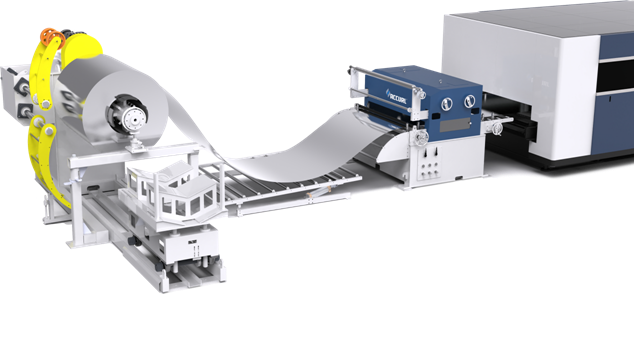

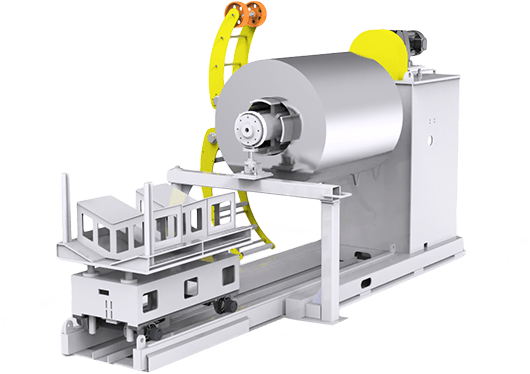

Safety Uncoiling Process

- The heavy-duty decoiler adopts a modern electric control system. With built-in safety protection logic control, it has a maximum protection of operator safety. And the robust mechanical structure design also ensures a stabilized uncoiling

Wide Loading Capacity

- The heavy-duty decoiler has HE-machine designed spindle structure. It has an outstanding load-bearing performance and fatigue resistance, which can load coil weight up to 15tons.

Automatic Operation

- The heavy-duty decoiler machine equips several control arms to achieves an automatic coil loading, loading, and threading. A functional control console can manage all the processes.

Advanced

- Coils up to 6 ~ 15 tons

- Coil width up to 1250 ~ 1500 mm

- Thickness : up to 0.5 ~ 2 mm

- CE standard electric control system

- Hydraulic cylinder drive coil car lifting

- Part length has no other limit than available space in the shop

- Pneumatic coil limiting device with handwheel adjustment

- Pneumatic drive coil hold-down arm with motorized PU pressing wheel

- One coil of 1 mm (19 Ga) thick material is about 2000 meters (6500ft) of material which can be processed, non-stop, and with a very limited scrap level.

Linecut® Straightener

With Straightener System’s Custom-Made Design and Appropriate Rollers Enables to Flatten the Bent / Distorted Sheet Materials and Coil at the Desired Tolerance.

Straightener For Coil Feed Line:

- The Straightener System, Which Is Suitable to Flatten Materials with Different Thicknesses and Material Types, Are Manufactured with Steel Construction Body.

- By Means Of Such Construction, The System Can Be Used for Many Years Without Any Damage. It Is Designed to Work Without Scratching or Damaging the Processed Material.

Line Structures and Development Process

Geometry

The geometry of the equipment, particularly the parallelism of the rolls, is vital in order to achieve optimum straightening. Our frames, built from iron castings, are machined on precision machining centres. The rolls are guided by low backlash needle bearings and immobilised transversely by needle thrust bearings or ball bearings

Advanced For Straightener

- Coil width up to 1250 ~ 1500 mm

- Thickness : up to 0.5 ~ 2 mm

- Pneumatic swing arm for coil threading assist

- Self-centering coil guide rollers

- Worm gear adjustment of upper rollers

- Pneumatic upper rollers release

- Motorized pass line height adjustment +/- 100mm

- 7pcs high-quality GCr15 straightening rollers, with bottom gear drive, up4/down3

- Adjustable tailout support bracket for smooth delivery of material from the feeder to the press

HI-SPEC Rolls

- Special care is given to the production of the rol- lers, which are case-hardened, ground and trued to guarantee maximum impact toughness and hardness of 60 HRC at a depth of 1.5 mm.

Backup Rolls

- For the units designed for heavy gauge or very wide materials, all the rolls are supported by from 1 to 7 rows of backup-rolls, depending on the width.

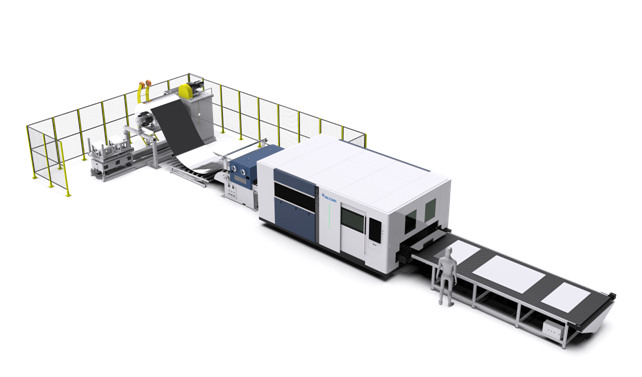

Linecut® Flexible Manufacturing System:

ACCURL® FMS line manages the material flow in flexible ways and reduces the lead time from raw material components. FMS stands for Punching + Cutting + Buffering + Bending.

The productivity offered by this concept derives from integration of:

- Versatile servo-electric punching

- Integrated servo-electric shearing

- Servo-electric bending

- Automatic, flexible material flow and

- Sophisticated software

Structure and Function

- Laser LINECUT

- Turret Punch Press ES-NT-30

- Sorting robots Systems

- A set of conveyor rollers

- Panel Bender PBE1400

- Palletizing Robot System

- The Production can effectively ensure product quality, improve production efficiency and reduce production costs.

High Power CW Fiber Laser For Metal Cutting

The new generation of IPG flagship YLR lasers takes their famous performance to a whole new level.the unrivaled combination of high power, ideal beam quality, unsurpassed reliability and industry-leading wall-plug efficiency delivers the best value on the market.

Features Of IPG Fiber Laser

- Average Power up to 6 kW*

- Built-in Diagnostics with Web Connectivity

- Record Energy Efficiency >40 %

- Extremely Small Size and Low Weight

- Exceptional Operation in High Humidity Environment

- Various Steels, Al, Cu, Ti Alloys, and Other Metals

- YLR-U Series incorporates the latest advancements in IPG world-leading industrial pump diode packaging technology and are the only hermetically sealed mid-power lasers on the market that can operate in extremely high humidity environments up to 90% relative humidity.

Ultra-Compact Fiber Laser For Metal Cutting

Central Wavelength Range | 1070 ±5 nm |

Mode of Operation | CW/ Modulated |

Modulation Frequency | 0-5 kHz |

Maximum Average Power* | 2Kw, 3Kw, 4Kw,6kW YLR SERIES |

Power Tunability | 10-100 |

Output Fiber Core Diameter*** | 100μm, 150μm, 200μm |

Wall-plug Efficiency | >40 % |