Description

CUSTOMER GROWTH MUST GO ON!

With all proper procedures in place, we’re still continuing to get our trusted customers’ machine solutions out the door & on their floor ASAP! This beautiful piece of equipment is on its way to Sunny SoCal!

ACCURL13’ X 150T GeniusPlus6+1 Axis Press Brake LOADED with DA66T CNC Control, Wila Clamping W/STLand 4-Axis Servo Backgauge, Hybrid Servo ECO-Energy Savings drive, and much more!

We are continuously monitoring the situation of COVID19 in order to keep our employees, customers and vendors safe.

We’ve adapted our way of doing business, using our advanced technologies for remote connectivity and remote support.

Our sales, service and parts department are working constantly to guarantee we can still meet all of your expectations, despite the difficult and challenging situation.

We would like to thank all of our current clients who have trusted us with their businesses, along with our new customers who are purchasing and receiving new equipment and moving forward with their projects, to be ready and competitive when this temporary challenge is over.

Thank you.

Stay strong and healthy,

we’ll all get through this together!

Click to download Accurl press brake Europro CNC 2D control brochure

STANDARD EQUIPMENT

- DELEM DA-66T CNC control unit with 2D graphics

- 6+1 axis CNC

- Y1, Y2 precision ram positioning

- Standard BGA-4 for X, R ,Z1 ,Z2-axis ( X=800mm,R=200mm)

- DELEM CAD/CAM Profile-T3D Expert 3D Offline Software

- ACCURL PRO CNC motorized wave crowning

- Large trio of value

- Large open height

- Large stroke

- Large throat depth

- HOERBIGER hydraulic valve block, pump and valves

- High Siemens efficiency motor– class IE3

- Hybrid ECO Function for energy-saving drive

- Rear cover: Safety barriers (Category IV)

- Sheet metal frontal supports

- Front and rear lighting

- Industry 4.0 of Productivity Monitor (software version V3.5.3)

- CE Norms: OEM Embedded Lazersafe Systems PCSS A0 + LZS-2 Block Laser (Category IV)

DELEM DA66T 3D CNC CONTROL UNIT

The DELEM DA-66T offers 2D programming that includes automatic bend sequence calculation and collision detection. Full 2D machine set-up with multiple tool stations giving true feedback on the product feasibility and handling

The application of Multi Touch technology reduces the number of keyboard- and button actions to an absolute minimum. The innovative Smart Draft, Design/Bending Multitasking, Step Previewer and Combined Icons features allow the operator a straightforward, intuitive control of the entire production cycle.

DELEM DA-69T features:

- 2D/3D graphical touch screen programming mode

- 3D visualization in simulation and production

- 17″ high resolution color TFT

- Full Windows application suite

- Delem Modusys compatibility (module scalability and adaptive)

- USB, peripheral interfacing

- Open system architecture

- Sensor bending & correction interface

Click to download DELEM DA66T DA69T CNC control brochure

OEM EMBEDDED LAZERSAFE SYSTEM FOR ACCURL PRESS BRAKE

Performance without compromise.™

ACCURL® use LazerSafe LZS-2 guarding system offers a highly effective solution for both operator safety and machine productivity. Designed for use with Lazer Safe’s PCSS A Service, the Lazersafe is category 4 compliant and meets the world’s most demanding international safety standards(CE Certified Category 4 Safety Controller with integrated).

Advantage:

- The most advanced laser systems

- Safety PLCs with manage and monitor

- Constant monitoring of parameters related to safety

Optional:

- Lazersafe-PCSS A0 LZS-XL

- Lazersafe-PCSS IRIS

Click to download Lazersafe system brochure

WILA® NEW STANDARD CLAMPING SYSTEM FOR PRESS BRAKE

The Wila’s ‘New Standard’ Tooling System has become market leader for precision, quality and flexibility for the Accurl press brake. the WILA’s state-of-the-art clamp systems offer optional for the ultimate efficiently changing tools with Smart Tool Locator® (STL)* have made the changeover process easier and safer. Premium is available as an option.

Advantage:

- Hydraulic power source

- Quick clamping for Europe style tooling

- Simple push-button loading

- Max. load head/shoulders 180 t/m

Optional for Smart Tool Locator® (STL)

Increase your press brake productivity

- The Smart Tool Locator (STL) further increases your press brake productivity. The system indicates by means of built-in LED’s the right clamping position of your tooling during tool set up and indicates the active tool location in production mode.

- The Smart Tool Locator offers significant benefits in speed,precision and flexibility.

LASER CHECK Bending Angle Measurement System:

- Laser Check, manufactured by Data M Engineering, is a bend angle measurement and correction system by means of a laser beam. The device is made of a laser and a camera on both sides of the bending line. Detection is carried out in this way.

Advantage:

- A laser beam is projected on the sheet metal surface

- The camera detects the laser beam

- The angle between the beam and the camera axis determines the bend angle.

- Force reduction + calculation of the springback

- Standard tooling is applicable – no extra cost for internal measuring units

- Automatic angle correction

Click to download Bending Angle Measurement System brochure

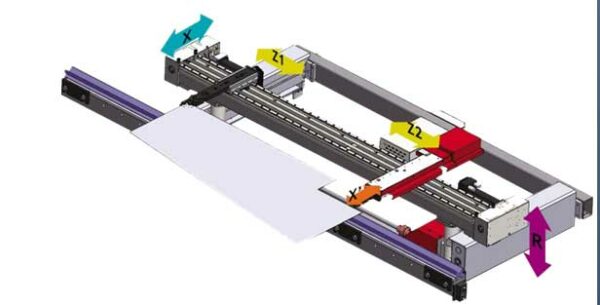

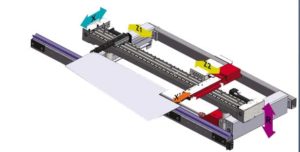

BGA Series BACK GAUGE FOR CNC PRESS BRAKE

ACCURL® press brakes are provided are equipped with BGA-2-6-axis CNC backgauge constituted by a solid structure in order to assure the best repetitiveness and high precision in axes positioning

ACCURL 2-Axis CNC BackGaugeBGA-2 for X, R-Axis

ACCURL 4-Axis CNC BackGaugeBGA-4 for X R, Z1, and Z2-Axis

ACCURL 5-Axis CNC BackGaugeBGA-5 for X R, Delta X, Z1, Z2-Axis

ACCURL 6-Axis CNC BackGaugeBGA-6 for X1 X2, R1 R2, Z1 Z2-Axis

Stroke X = 800 mm

Max. Speed X = 450 mm/s

Stroke R = 200 mm

Max. Speed Z = 550 mm/s

Advantage:

- X, R-Axis with HIWIN linear guide and Ball Screw.

- CNC (Manual) Z1,Z2-axis with HIWIN linear guide.

- Unprecedented positioning repeatability of ±0.05 (optional ±0.01).

- To reach maximum versatility you can automate both backstops with X1-X2 axes, reaching an angle of 80° on oblique bends.

*** Note: As products are constantly updated, please contact us for latest specifications. ***