ACCURL is set to embark on the construction of a new state-of-the-art smart green factory, marking a significant milestone in the field of sustainable and digital production methods.

As a globally recognized provider and manufacturer of sheet metal machinery solutions, Accurl is known to be at the forefront of driving technological innovation and transformation. Now, Accurl is once again leading the industry by announcing the creation of an entirely new smart green factory, seamlessly integrating a digitized workshop with a green smart factory. This innovative investment not only demonstrates Accurl’s commitment to environmental sustainability and digital transformation but also showcases the future possibilities of sustainable green development to the global equipment manufacturing industry.

Accurl, a leader in the global sheet metal machinery field, has just held a groundbreaking ceremony for the construction of a new generation green smart manufacturing facility. The new factory will construct a workshop area of 61300 square meters, a green area of 3115 square meters, and an administrative space of 3198 square meters. The design and smart layout of the new factory were collaborated on by Technische Universität Berlin in Germany and the renowned TIANYI ARCHIITECTURE design institute. For the construction of the new factory Accurl will invest 41.50 million dollars. The new facility is expected to be ready by December 2024. The production capacity of the new factory will be further increased, producing in total 1000 Sets machines, including laser cutting machine & CNC press brake(various automation production lines). “With the construction of the new factory, Accurl will continue to uphold its excellent craftsmanship and continuous innovation mission, providing customers with higher quality machine tools and services while making a greater contribution to the industry’s sustainable development”, says Cameron Lee, Managing Director of Accurl.

The characteristics of Accurl’s new factory

To further highlight the advantages of green energy conservation and reduce carbon emissions, especially in the application of photovoltaic energy, the new factory will save 825.12 tons of carbon dioxide, 271.45 tons of standard coal, and 225.11 tons of smoke and dust annually – compared to conventional production methods. In addition to being environmentally friendly, Accurl’s new factory also has a highly innovative customized production capability, a temperature-controlled dust-free workshop, robotic smart welding capacities, a digital connected workshop with a powerful MES manufacturing execution system. Professional teams will use lean management methods for further innovation to be coming. Accurl’s goal with the new facility is to strengthen its leading position in production technology, combining digital manufacturing with green energy-saving technology and presenting a series of features and advantages that lead the way into the future.

“Accurl’s new factory combines digital manufacturing, smart technology, and green energy, setting a new benchmark for the sheet metal machinery manufacturing industry. This modern green smart factory will play a pivotal role in the production processes of ACCURL’s core products – electric energy-saving servo press brakes and laser cutting machines, guiding the equipment manufacturing industry into a more efficient, environmentally friendly, and innovative future. Accurl leads the way in the future of smart manufacturing, co-creating a new chapter in the era of green technology”, says Cameron Lee.

Demonstration Centers in Anhui ACCURL: Display of Cutting, Bending and More

Are you interested in experiencing laser and bending solutions live in action away from the trade fair? Visit us in China in our demonstration factory – in Bowang District Bowang Equipment Industrial Park.

Make an appointment now at (+86) 555-2780553 or by e-mail to [email protected].

“Accurl’s new factory combines digital manufacturing, smart technology, and green energy, setting a new benchmark for the sheet metal machinery manufacturing industry. This modern green smart factory will play a pivotal role in the production processes of ACCURL’s core products – electric energy-saving servo press brakes and laser cutting machines, guiding the equipment manufacturing industry into a more efficient, environmentally friendly, and innovative future. Accurl leads the way in the future of smart manufacturing, co-creating a new chapter in the era of green technology”

“Accurl’s new factory combines digital manufacturing, smart technology, and green energy, setting a new benchmark for the sheet metal machinery manufacturing industry. This modern green smart factory will play a pivotal role in the production processes of ACCURL’s core products – electric energy-saving servo press brakes and laser cutting machines, guiding the equipment manufacturing industry into a more efficient, environmentally friendly, and innovative future. Accurl leads the way in the future of smart manufacturing, co-creating a new chapter in the era of green technology”Cameron Lee

Managing Director | ACCURL CNC Machine Tools (Anhui) Co., LTD

Accurl is establishing a leading “Smart Sheet Metal Equipment Manufacturing Factory”:

– Workshop Area: 61,362 square meters

– Green Area: 3,115 square meters

– Office Area: 3,198 square meters

© Accurl

The groundbreaking ceremony of Accurl’s new factory:

The groundbreaking ceremony for the annual production of 1000 sets laser cutting machine and CNC press brake in the new factory of Accurl was successfully held.

© Accurl

A New Era of Green Smart Manufacturing:

Accurl’s new factory will achieve self-sufficiency in internal power through a solar power system, reducing reliance on traditional energy sources and further minimizing the carbon footprint, leading the way in the development of the green era. This will be accomplished through a unified allocation of green energy usage facilitated by a digital green energy management system.

© Accurl

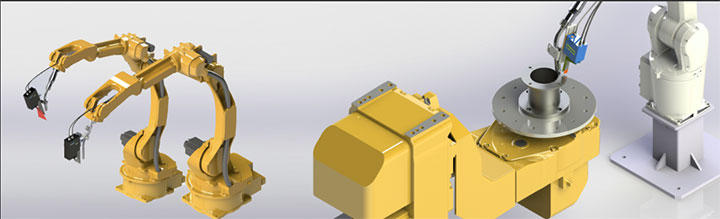

ACCURL’s in-house developed robotic welding enhances machining processes:

This smart welding technology elevates the welding process for machining, ensuring accuracy and process refinement.

© Accurl

AGV smart Logistics and Warehouse System Boosts Efficiency

Accurl employs smart warehousing AGV robots featuring a flatbed truck chassis with a spacious platform, robust load-bearing capacity of up to 500KG, perfectly tailored for the production scenes at Accurl’s new factory. Even after working hours, AGVs autonomously identify and transport goods, enhancing overall factory production efficiency.

© Accurl

Digitalized Workshop Leading the Future:

Accurl’s laser cutting machine control system encompasses digital interfaces and innovative technologies, facilitating digital data integration between customers and equipment through the MES system. The screenshot shows a control screen of a digital linked workshop.

© Accurl

About Accurl

Your Partner for Cutting, Bending & Pressing

Since its establishment in 1988, ACCURL has been dedicated to quality and customer satisfaction, customizing CNC press brakes, laser cutting machines, and automated sheet metal machinery to meet customer demands. Continuously advancing ACCURL’s brand and technological innovation, the company has made outstanding contributions to the industry’s development. As one of China’s earliest manufacturers of CNC press brakes and fiber laser cutting machines, ACCURL has grown to become a global top-ten leader in the sheet metal machinery field, leading in energy efficiency, environmental protection, and technological advancement and application.

While we started as the earliest batch sheet metal working machines manufacturer for CNC press brake and fiber laser cutting machines in China, we’ve since grown into a TOP 10 worldwide industry leader and lead the charge in energy efficient, environmentally friendly, and technological advancements. Accurl now has over 160 employees and the team is still growing.

Learn more: https://www.accurl.com/about-us/