Fiber laser cutting stands at the forefront of precision manufacturing, offering unmatched efficiency and accuracy. This technology revolutionizes how industries like manufacturing and advertising handle metal cutting, making it essential to choose the right fiber laser cutter for your needs.

What is Fiber Laser Cutting?

Fiber laser cutting is a precise and efficient laser cutting technology that utilizes a laser beam generated through a fiber optic cable to slice through materials.

This technology harnesses the power of fiber optics and a gain medium to amplify the beam, providing a cutting tool that is superior in speed and accuracy.

Fiber laser cutting is ideal for the manufacturing industry, as it supports cutting a diverse array of materials including metals like stainless steel and carbon steel with exceptional edge quality and speed.

How To Select the Right Fiber Laser Cutter?

Selecting the right fiber laser cutter for your needs involves understanding various factors that influence performance and output.

We will help you identify the most critical elements to consider to ensure you invest in a machine that enhances your manufacturing operations efficiently and economically.

Material Thickness

Material thickness is a fundamental factor in choosing a suitable fiber laser cutter. Different machines are equipped to handle varying thicknesses of materials. The key is to select a laser cutter that can manage the maximum thickness you anticipate cutting. Here’s why this is crucial:

- Cutting Quality: Thicker materials require lasers with higher power output. Using a machine that isn’t capable of handling higher thicknesses can result in poor edge quality and increased wastage.

- Productivity: The right machine for the required material thickness ensures faster cutting speeds without sacrificing quality, thereby enhancing productivity.

- Cost-Effectiveness: Operating a machine within its optimal range of thickness minimizes wear and tear, reducing maintenance costs and prolonging the machine’s lifespan.

Part Sizes You Want To Produce

The dimensions of the parts you intend to produce are critical in selecting the appropriate fiber laser cutter. The capability to accommodate varying part sizes influences your choice, as the bed size of the laser cutter must match the largest piece you plan to fabricate. Here are aspects to consider:

- Capacity: Ensure the laser cutter can handle the maximum part size your projects require. This avoids the limitations that come with smaller machines which might not support expansion or larger projects in the future.

- Flexibility: A machine that offers flexibility in handling various sizes can provide more value, allowing you to take on diverse projects without the need for multiple machines.

- Precision: Larger machines must maintain high precision even at maximum capacity. It’s important that the increase in size doesn’t compromise the accuracy and quality of the cuts.

Automation Options and Features

Automation plays a pivotal role in modern fiber laser cutting systems, impacting both productivity and operational efficiency. When considering automation, focus on these features:

- Loading and Unloading Systems: Automated material handling can significantly reduce cycle times and labor costs. Systems that facilitate quick loading and unloading of materials streamline operations and increase throughput.

- Software Integration: Advanced cutting software can optimize cutting patterns to minimize waste and enhance cutting speed. Look for systems that offer user-friendly interfaces and compatibility with design software.

- Remote Monitoring and Control: Features that allow you to monitor and control the laser cutter remotely can enhance operational efficiency and enable proactive maintenance.

Total Productivity

Total productivity measures the overall efficiency and output of your fiber laser cutter. To evaluate this, consider the following:

- Cutting Speed and Quality: The speed at which the machine cuts without sacrificing quality is crucial. Higher speeds with precision are indicators of a superior laser system.

- Downtime and Maintenance: Analyze the expected maintenance needs and any associated downtime. Machines designed for easy maintenance with minimal downtime contribute to greater productivity.

- Energy Efficiency: Assess the power consumption in relation to output. Energy-efficient machines reduce operating costs and are beneficial for high-volume production environments.

Financing Options

Investing in a fiber laser cutter involves significant capital, but several financing options can make acquisition more accessible and financially sustainable. Make sure to research:

- Leases: Leasing a fiber laser cutter can be a viable option if you prefer not to commit capital upfront. Leases often come with the advantage of including maintenance in the contract, ensuring that the machine remains in optimal condition without additional costs.

- Loans: Loans provide another route to machine ownership, with the benefit of spreading the cost over time. It’s important to compare different loan terms from various financial institutions to secure the best interest rates and payment plans that suit your business cash flow.

- Grants and Subsidies: In some regions, grants or subsidies are available for manufacturing technology investments. These can reduce the initial cost and support advanced technological adoption in the manufacturing sector.

Selecting the right financing option depends on your company’s financial health, tax considerations, and long-term business strategy. Each option offers different benefits and should be carefully evaluated to ensure it aligns with your operational goals and financial capabilities.

Power Consumption

Considering the power consumption and efficiency of fiber laser cutters is critical when planning for long-term operational costs.

The power consumption of fiber laser cutters varies significantly depending on the machine’s wattage and operational efficiency. Most common models range from low-wattage systems suitable for fine, detailed work to high-wattage systems designed for cutting thick materials. Here’s how power impacts operations:

- Wattage Categories: Typical fiber laser cutters range from 500 watts to over 6,000 watts. Higher wattage machines can cut thicker materials but will use more power.

- Average Power Usage: The electricity consumption of a laser cutter depends on the cutting power and operational hours. For instance, a 2,000-watt machine generally consumes about 10 kW per hour, factoring in the total system’s efficiency.

- Cost Implications: Understanding the power requirements and efficiency of a fiber laser cutter is crucial for managing operational costs. Energy-efficient models, while potentially more expensive upfront, can significantly reduce electricity costs over time.

Table Size

The size of the table on a fiber laser cutter significantly impacts operational efficiency. Here’s why the right table size matters:

- Handling Capabilities: A larger table allows you to handle bigger sheets of materials like stainless steel or carbon steel, reducing the time spent on repositioning and additional cuts. This can lead to a smoother workflow and less waste.

- Flexibility in Projects: With a larger table, you can undertake a wider range of projects, from small intricate designs to large industrial parts. This flexibility is crucial for businesses looking to expand their market reach or diversify their product offerings.

- Efficiency: Properly sized tables reduce the need for multiple setups. Fewer setups mean quicker turnaround times and lower labor costs, which directly enhance productivity.

Selecting the right table size for your fiber laser cutter involves understanding the maximum material sizes you plan to use and the space available in your manufacturing facility.

Versatility

The versatility of a fiber laser cutter is determined by its ability to adapt to various production needs without requiring extensive retooling or setup changes. Here’s what makes a fiber laser cutter versatile:

- Software Compatibility: Advanced software integration allows for quick adjustments to cutting patterns and settings to handle various materials and thicknesses efficiently.

- Adjustable Settings: Machines with a wide range of power outputs and speed settings can easily switch between different types of jobs, from cutting thin sheet metal for intricate designs to slicing through thicker plates for structural projects.

Investing in a versatile fiber laser cutter means you can respond swiftly to customer requests and market changes, which is a significant competitive advantage in the fast-paced manufacturing industry.

Material Compatibility

Understanding the material compatibility of fiber laser cutters is essential, as different lasers excel with different materials based on their wavelength and power settings. Here’s how compatibility varies:

- Fiber Lasers for Metals: Fiber lasers are ideal for cutting metals like aluminum, brass, and stainless steel due to their high precision and speed. The fiber optic cable and the gain medium in these lasers produce a beam that is finely focused yet powerful enough to cut through thick metal efficiently.

- Versatility with Materials: Some fiber lasers are equipped to handle a variety of materials beyond metals, including plastics and composites, by adjusting power levels and frequencies. This ability allows businesses to use a single machine for multiple applications, enhancing the ROI.

Manufacturer: Reputation and Reliability

When selecting a fiber laser cutter, considering the manufacturer’s reputation and reliability is crucial. Here are the factors to assess:

- Reputation: Look for manufacturers known for consistency and excellence in the manufacturing industry. A reputable brand is often recognized through industry awards, positive reviews from other users, and a strong presence in the market.

- Quality of Components: The durability and performance of a fiber laser cutter largely depend on the quality of its components. High-quality parts ensure fewer breakdowns and lower maintenance costs over time.

- After-Sales Service: Effective after-sales service is essential. This includes access to technical support, availability of spare parts, and the provision of regular service to ensure the machine’s longevity and performance. A manufacturer’s commitment to customer support often reflects in their service agreements and response times.

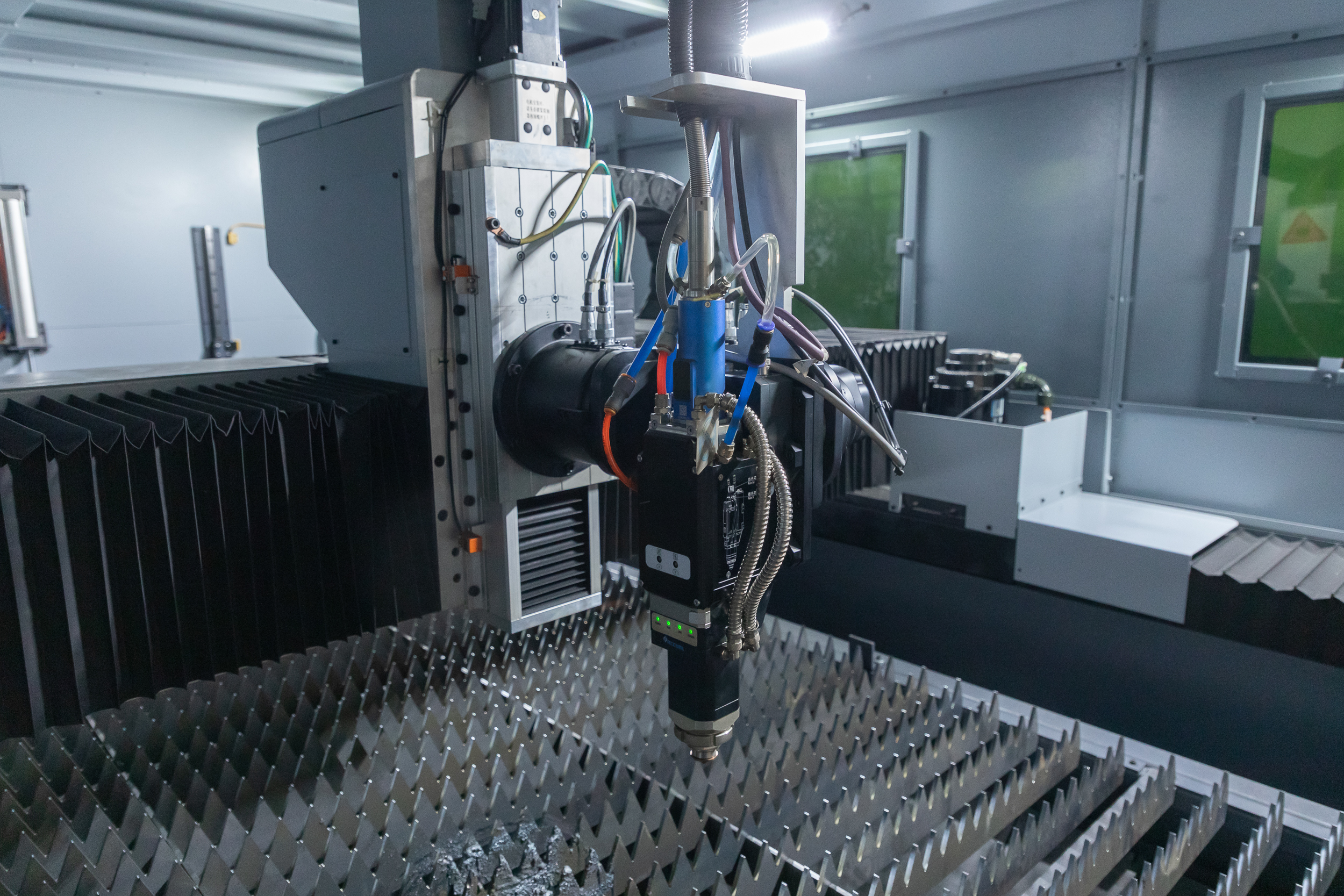

ACCURL

ACCURL exemplifies a manufacturer with a strong reputation and reliable products.

Established in 1988, ACCURL was among the first in China to produce CNC press brakes and fiber laser cutting machines. Known for their structural analysis and optimal machinery design, they manufacture ultralight, high-precision, high-energy 2D fiber laser cutters.

АCCURL fiber laser cutters are notable for their high dynamics and superior quality, achieving positioning speeds of up to 180m/min and acceleration of 3G. They offer a range of machines equipped with 1 to 30kW IPG fiber laser sources, ensuring suitability for various industrial applications.

ACCURL’s commitment to excellence is also evident in our after-sales service, offering extensive consultation services on machine operation, programming, and maintenance, backed by a supply of original spare parts to guarantee performance and durability.

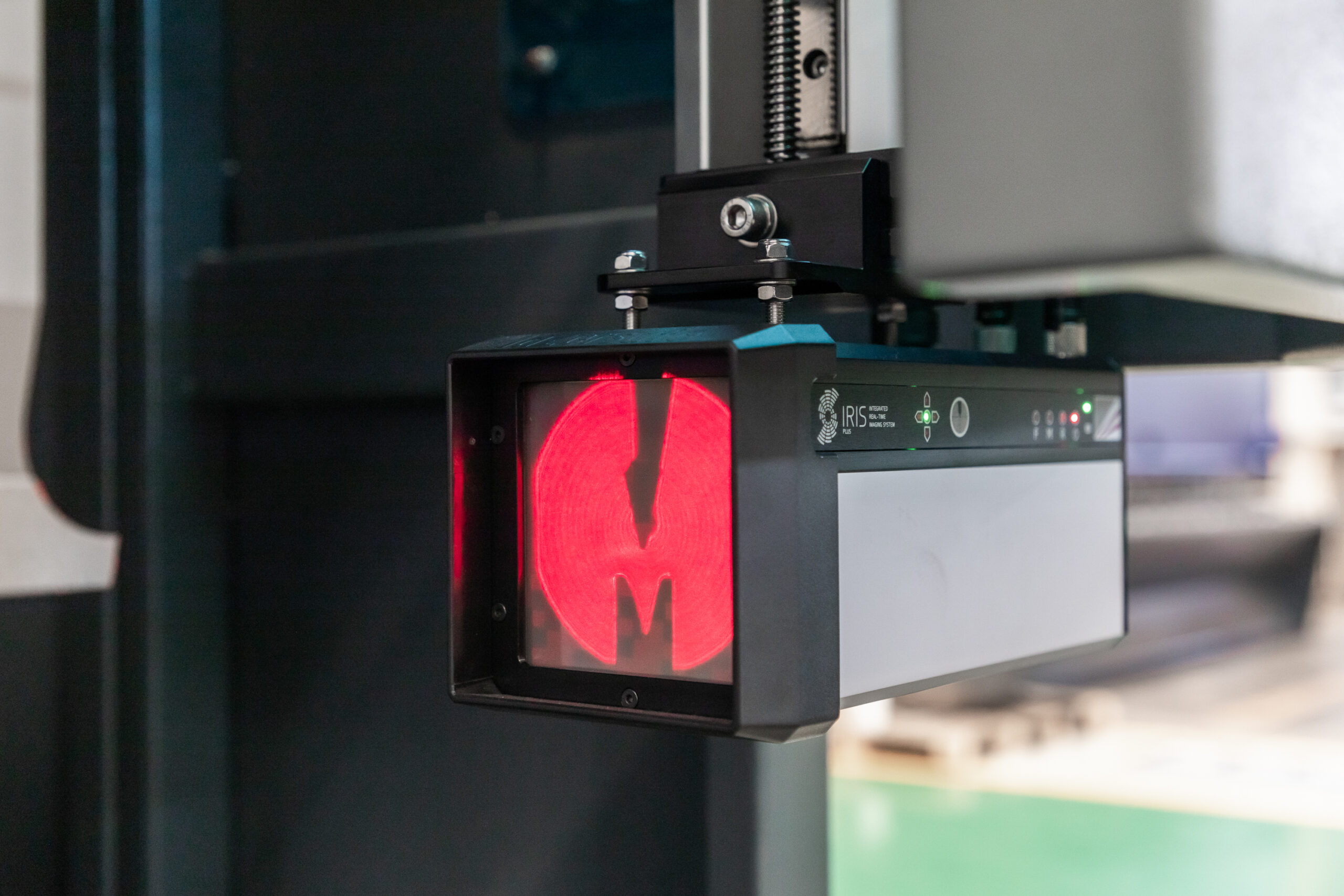

Software Integration

The integration of sophisticated software is another critical factor in choosing the right fiber laser cutter. Effective software integration can enhance the machine’s functionality, improve user experience, and increase productivity through more efficient operations.

Here are some advantages:

- Streamlined Operations: Advanced software helps streamline operations by automating many processes that would otherwise require manual input, thus reducing error and increasing efficiency.

- Enhanced Capabilities: With the right software, fiber laser cutters can perform complex cutting tasks more accurately and quickly, adapting to different materials and designs with ease.

- User-Friendly Interface: Modern fiber laser machines come equipped with user-friendly interfaces that make it easier for operators to manage jobs and adjust settings on the fly, which is crucial for optimizing workflow and reducing downtime.

Making the Decision: Practical Examples with 3 Different Industries

To give you a more practical approach, we examine three businesses, each differing in size, industry, and operational needs, to illustrate how to choose the most suitable fiber laser cutter for each scenario.

Example 1: Small Custom Jewelry Shop

A small custom jewelry shop specializing in intricate designs on metals like brass and aluminum.

Requirements:

- Precision: High precision for detailed work on precious metals.

- Material Thickness: Typically 0.5mm to 3mm.

- Machine Type: A lower power fiber laser cutter, around 500W to 1kW, which is ideal for cutting thin metals with precision without excessive energy use.

Suitable Fiber Laser Cutter: A compact fiber laser with a 1kW power rating, capable of handling detailed designs on thin metals. The machine should also be equipped with fine control settings to adjust the laser for high precision and minimal material waste, crucial for expensive materials like gold and silver.

Example 2: Medium-Sized Automotive Parts Manufacturer

Production of automotive parts requiring cutting of materials like carbon steel and stainless steel. Requirements:

- Material Thickness: Up to 12mm thickness.

- Productivity: Needs a machine that supports high throughput to meet customer orders and maintain supply chain commitments.

- Machine Type: At least a 3kW to 5kW fiber laser cutter to efficiently handle thicker materials with speed and precision.

Suitable Fiber Laser Cutter: A robust fiber laser cutter with a 5kW power output, featuring automated loading and unloading capabilities to enhance production efficiency. This system should also support fast cutting speeds and include durable components that can withstand the rigors of a high-volume manufacturing environment.

Example 3: Large-Scale Metal Fabrication Facility

Large-scale fabrication of structural components for construction and heavy machinery, dealing primarily with thick metal sheets. Requirements:

- Material Thickness: Often over 20mm.

- Scalability and Versatility: Requires a machine that can scale operations up or down based on project demands and handle a variety of metals, including heavy steel plates.

- Machine Type: High-power fiber laser cutters, preferably above 10kW, with extensive table sizes to accommodate large materials.

Suitable Fiber Laser Cutter: A high-end fiber laser cutting system with at least a 12kW power rating, capable of cutting extremely thick materials. The machine should feature a large cutting table and advanced software integration for managing complex cutting tasks, ensuring precision across large-scale projects.

Additionally, such a cutter should have a reinforced structure to handle heavy materials and high-intensity use, with a focus on minimizing downtime and maintenance costs.

Conclusion

Selecting the right fiber laser cutter is contingent on a detailed assessment of your business’s specific needs, material types, and production demands.

When choosing a fiber laser cutter, consider not only the technical specifications but also factors such as software compatibility, machine durability, and after-sales support to ensure you invest in a solution that effectively meets your operational needs and enhances your manufacturing capability.

Аs, a leading manufacturer of fiber laser cutters, ACCURL is always ready to equip you with all the knowledge you need to make the perfect choice. Feel free to contact us and our expert will answer all your questions.