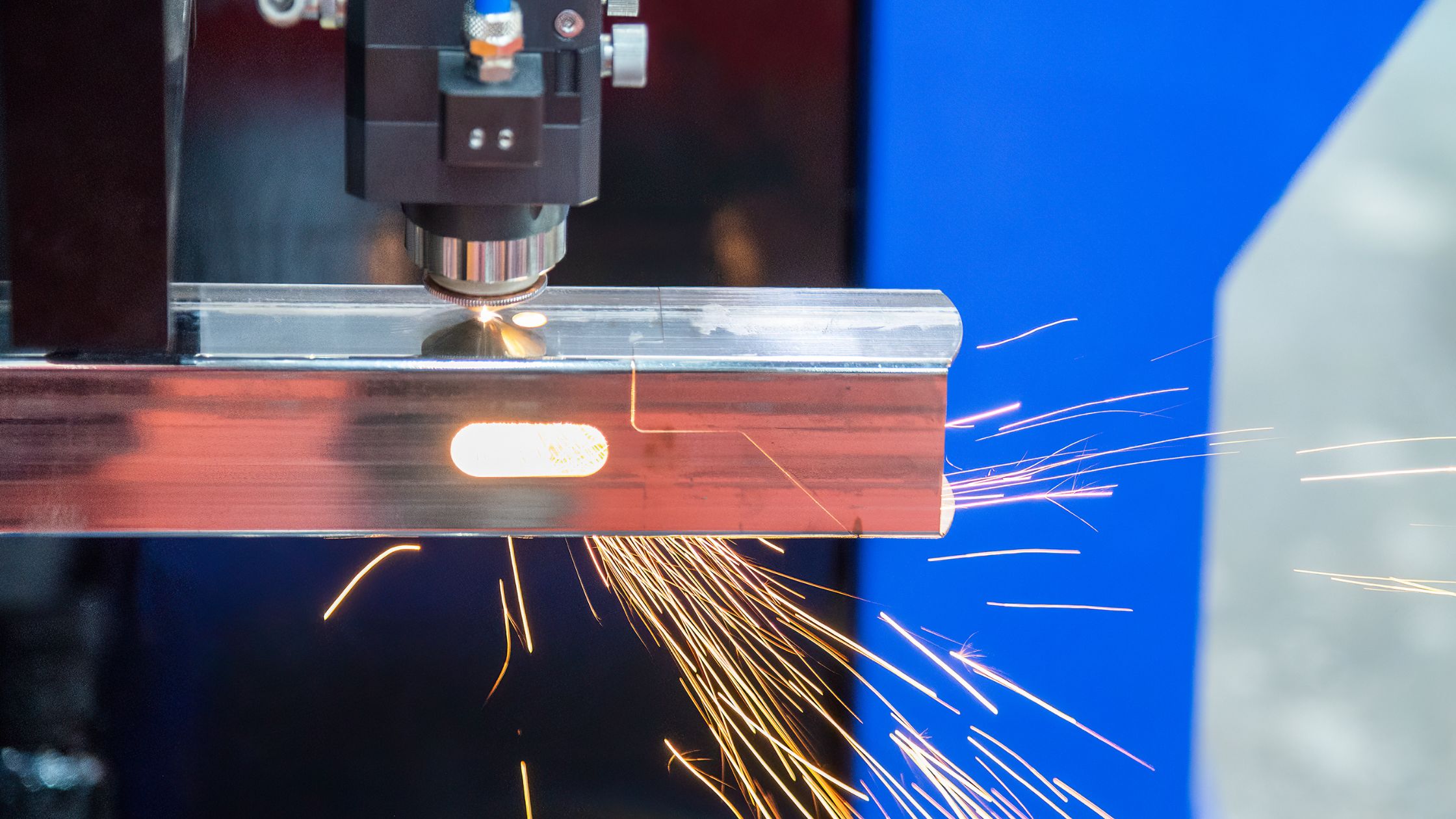

In the realm of metal fabrication, the advent of fiber laser cutting has been nothing short of revolutionary. This powerful technology harnesses light to slice through metal with unprecedented precision and efficiency.

But what exactly sets fiber laser cutting apart from other metal cutting methods?

What is Fiber Laser Cutting?

Fiber laser cutting is a type of laser cutting technology that uses a laser made from optical fibers doped with rare-earth elements such as erbium, ytterbium, neodymium, or dysprosium. Unlike traditional lasers, which rely on gases or crystals, fiber lasers utilize solid-state components, making them more efficient, reliable, and capable of delivering a high-quality laser beam.

This innovative technology has rapidly become the method of choice for cutting various metals, including stainless steel, carbon steel, aluminum, and copper, offering advantages in speed, precision, and cost-effectiveness that are hard to match.

What are the Advantages of Fiber Laser Cutting?

Fiber laser cutting, with its solid-state laser technology and use of optical fibers doped with rare-earth elements, provides a clear advantage over traditional cutting technologies like CO2 lasers and plasma cutting.

Let’s dissect these advantages to understand why fiber laser cutting has become the preferred choice for many.

Efficiency and Speed

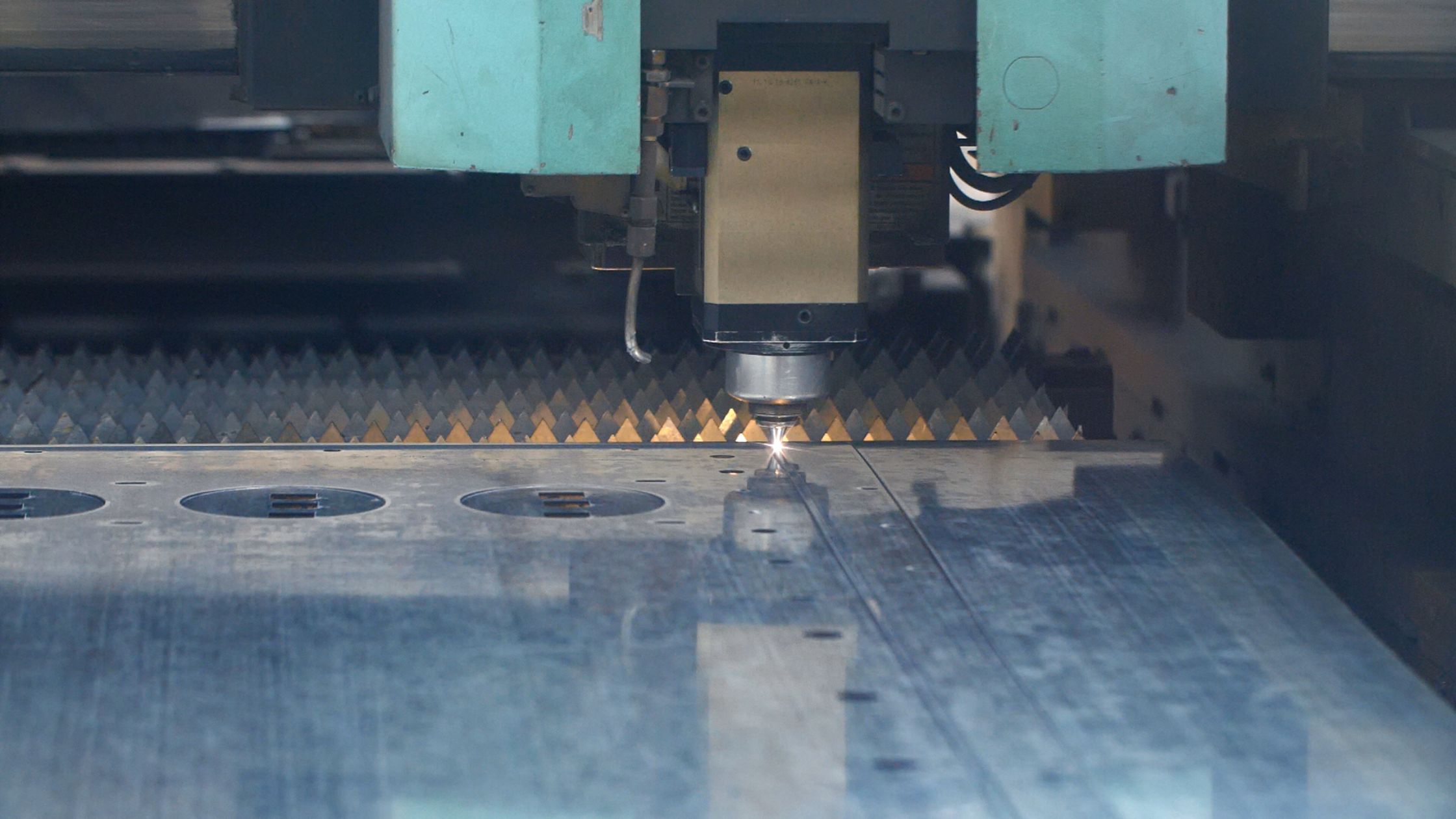

One of the most pronounced benefits of fiber laser cutting machines is their efficiency and speed. This is not just in comparison to older laser technologies but also when evaluating against plasma cutting methods. The fiber laser’s superior beam quality allows for faster cutting speeds, particularly in thin to medium-thick metal sheets.

- Speed comparisons reveal that fiber lasers can cut at speeds up to three times faster than CO2 lasers on thin materials.

- Efficiency metrics further underscore the advantage, with fiber lasers showing electrical efficiency rates significantly higher than those of CO2 lasers. This efficiency not only speeds up production times but also reduces energy consumption, making fiber lasers a more sustainable option.

This enhanced efficiency and speed mean that companies can complete more orders in less time, leading to increased productivity and profitability. The ability to rapidly cut through materials without compromising on quality is a game-changer in the fast-paced manufacturing sector.

Precision and Quality of Cut

Precision and quality are hallmarks of fiber laser cutting. This technology offers a level of accuracy and edge quality that is difficult to achieve with other cutting methods.

- The accuracy of fiber laser cutting machines can be as precise as 0.05mm, significantly superior to that of CO2 lasers and plasma cutters.

- The edge quality is equally impressive, with minimal kerf width and a smooth finish that often eliminates the need for post-processing.

This precision is crucial for industries where even the smallest deviation can affect the functionality of a component, such as in the aerospace or electronics sectors. The minimal heat affected zone (HAZ) also ensures that the structural integrity of the material is preserved, further enhancing the quality of the cut.

Cost-Effectiveness

The long-term savings associated with fiber laser cutting are substantial. The initial investment might be higher than that for traditional cutting machines, but the lower maintenance costs, reduced energy consumption, and increased throughput translate into significant cost savings over time.

- The efficiency of fiber lasers means lower electricity bills.

- Their solid-state design and minimal moving parts reduce maintenance requirements and associated costs.

Versatility Across Materials

The ability to cut a wide range of materials is another significant advantage of fiber laser technology. This versatility is essential for metal fabrication companies that work with various metals and need to switch between them frequently.

Fiber lasers can easily cut through stainless steel, carbon steel, aluminum, brass, and copper, among others. This wide range of compatible materials means that companies can use a single machine for multiple applications, increasing their operational flexibility.

Environmental Friendliness

Fiber lasers signify a leap towards more sustainable industrial practices. Unlike traditional CO2 laser cutting machines, which require higher power levels and emit more carbon, fiber laser cutting machines excel in their energy efficiency and reduced carbon footprint. This aspect is crucial as industries worldwide strive to lower their environmental impact.

Low Maintenance

Maintenance demands can significantly affect the operational costs and uptime of cutting machines. Fiber lasers, with their solid-state design and minimal moving parts, stand out for their low maintenance requirements.

Greater Reliability

The reliability of a cutting machine is critical for maintaining productivity and meeting production deadlines. Fiber laser cutters, renowned for their robust design and minimal consumables, offer unparalleled reliability.

Their long service life ensures consistent performance over time, making them a dependable choice for businesses aiming to optimize their production capabilities without the frequent interruptions associated with maintenance and repairs.

Small Footprint

Space is often at a premium in manufacturing facilities. Fiber laser cutting machines, recognized for their efficient use of space, require less floor area than their counterparts. This small footprint allows companies, especially those with limited space, to maximize their operational capacity and streamline their production processes.

No Heat Damage to Materials

One of the most significant advantages of fiber laser cutting is its ability to minimize heat damage to the surrounding material. The precision and control over the laser beam ensure that the heat affected zone (HAZ) is significantly smaller than that produced by CO2 lasers, preserving the integrity and properties of the material being cut.

Superior Edge Quality

The quality of the cut, especially the smoothness of the edges, is paramount in metal fabrication. Fiber lasers excel in producing cuts with exceptionally smooth edges, which often eliminate the need for additional finishing processes. This contrasts sharply with CO2 lasers, where the quality of the cut might require further processing to achieve the same level of smoothness. The high beam quality and precision focusing of fiber lasers result in cleaner cuts, reducing the time and cost associated with post-cutting finishing.

Ability to Cut Reflective Materials

Reflective materials like copper and aluminum present challenges to traditional CO2 lasers due to the risk of back reflections, which can damage the equipment. Fiber lasers, on the other hand, can cut highly reflective materials without such risks, thanks to their different wavelength and beam characteristics. This capability opens up new possibilities for working with a broader range of materials, enhancing the versatility of fiber laser cutting machines in diverse applications.

Integration with Automation and Software

The integration capabilities of fiber laser cutting machines with digital controls and automation systems significantly enhance precision and efficiency. This seamless integration allows for more sophisticated control over the cutting process, optimizing production workflows and reducing human error. Compared to other laser technologies, fiber lasers offer a more straightforward and effective way to incorporate automation, making them ideal for advanced manufacturing environments.

Low Operational Costs

Fiber lasers stand out for their energy efficiency and low maintenance requirements, leading to significantly lower operational costs over time. The solid-state design and minimal moving parts of fiber laser machines contribute to reduced maintenance demands and downtime, offering a stark contrast to CO2 lasers, which typically involve higher operating and maintenance costs.

Consistent Quality Over Time

Maintaining a consistent level of cutting quality over extended periods is crucial for industrial applications. Fiber lasers excel in this aspect, providing stable performance and preserving cut quality even after extensive use. This reliability is a significant advantage over other laser types, where the quality might degrade over time due to wear and maintenance issues.

Minimal Heat Affected Zone (HAZ)

The precision of the laser beam in fiber laser cutting minimizes the heat affected zone (HAZ) surrounding the cuts. This precision protects the integrity of the material, preserving its mechanical and physical properties. Compared to CO2 lasers, fiber lasers offer more controlled and focused cutting, reducing the extent of heat damage and ensuring higher-quality finishes.

High Beam Quality

The beam quality of fiber lasers is unmatched, characterized by a straighter, more focused trajectory. This high beam quality enables precise and detailed cuts, setting fiber lasers apart from other technologies. The ability to produce such high-quality beams allows for intricate cutting work, which is especially beneficial in applications requiring fine detail and precision.

Reduced Setup Times

Flexibility and rapid turnaround times are crucial in today’s fast-paced production environments. Fiber lasers offer reduced setup times, allowing for quick changeovers between jobs. This capability is particularly valuable for short runs and rapid prototyping, where the ability to swiftly adjust to new specifications is essential. Compared to traditional cutting technologies, fiber lasers significantly streamline the setup process, enhancing overall productivity.

Greater Control Over Cutting Parameters

The precision in cutting that fiber laser technology offers is largely due to the superior control it provides over cutting parameters such as power, speed, and focus. This level of control allows operators to fine-tune the cutting process to match specific material characteristics and design intricacies, leading to higher quality cuts and reduced waste.

When compared to CO2 lasers, this greater control translates into enhanced efficiency and flexibility, empowering users to execute complex cuts with unparalleled accuracy.

Compatibility with Complex Geometries

Fiber lasers excel in cutting complex shapes and fine details with high precision. This capability is particularly advantageous for industries requiring intricate designs and tight tolerances, such as aerospace, electronics, and medical devices.

The focused and stable laser beam produced by fiber laser technology outperforms CO2 lasers in terms of the ability to handle complex geometries, ensuring that even the most delicate designs are cut cleanly and accurately.

Reduced Noise Levels

The operating environment is an important consideration in any manufacturing setting. Fiber laser cutters typically operate with significantly lower noise levels compared to traditional cutting methods, contributing to a more pleasant and less disruptive work environment.

This reduction in noise pollution not only enhances the comfort of operators but also complies with increasingly strict workplace safety regulations.

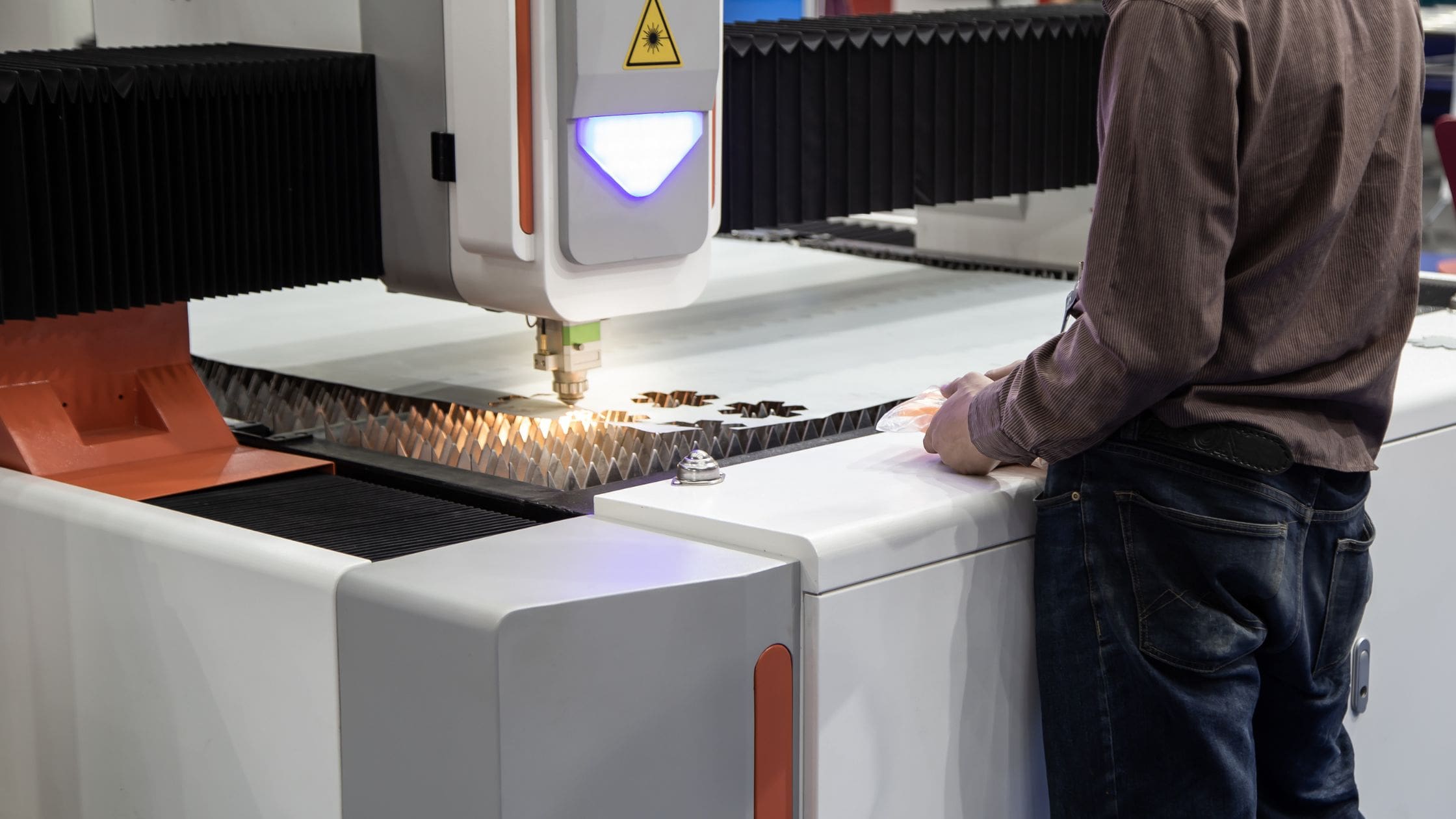

Enhanced Safety Features

Safety is paramount in the operation of any industrial machinery. Fiber laser cutting machines are designed with numerous safety features, including emergency stop buttons, enclosed cutting areas, and fume extraction systems. These features not only protect operators from potential hazards but also surpass the safety measures typically found in CO2 laser cutting machines, making fiber lasers a safer choice for manufacturers.

Lower Consumables Usage

The economic aspect of operating cutting machinery is significantly influenced by the cost and usage of consumables. Fiber lasers require fewer consumables such as lenses and nozzles compared to CO2 and other types of lasers, which directly impacts the cost-effectiveness of the technology. This lower consumable usage, coupled with reduced maintenance requirements, positions fiber lasers as a cost-efficient solution over the long term.

Integration with Industry 4.0

In the era of smart manufacturing, the ability to integrate with Industry 4.0 technologies is a significant advantage. Fiber laser cutting machines are at the forefront of this integration, offering compatibility with smart factory systems for real-time monitoring, predictive maintenance, and data analytics. This connectivity not only enhances operational efficiency but also provides insights into process optimization, making fiber lasers a key component in the future of manufacturing.

Support for Thin and Delicate Materials

One of the most distinctive benefits of fiber laser cutting is its unparalleled precision and control, making it supremely suitable for cutting thin and delicate materials without risk of damage or warping. This precision stems from the laser’s low heat output and high control over the laser beam, features that are not as finely tuned in CO2 laser systems.

CO2 lasers, while effective for a broad range of applications, can sometimes apply too much heat to delicate materials, leading to material deformation or damage. In contrast, fiber lasers can maintain material integrity even when working with materials as thin as a few micrometers.

Long Lifetime of Laser Source

The durability and longevity of the laser source in fiber laser systems are unparalleled, often exceeding 100,000 hours of operation. This extended lifespan significantly reduces the need for frequent replacements and downtime, contributing to higher operational efficiency and lower long-term costs.

In comparison, traditional laser sources, including those used in CO2 laser machines, typically have shorter lifespans, leading to increased maintenance and operational costs over time.

Reduced Operating Skills Requirement

Modern fiber laser machines are designed with user-friendliness in mind, requiring less specialized training for operation. This accessibility lowers the barrier to entry for new operators and can significantly reduce labor costs associated with training and operation.

By contrast, traditional laser systems, including CO2 lasers, might require more in-depth knowledge and experience to operate effectively, potentially increasing training costs and limiting operator flexibility.

Does Fiber Laser Cutting Have any Disadvantages?

While the benefits of fiber laser cutting are numerous, it’s important to acknowledge that no technology is without its limitations.

Understanding these challenges can help users make informed decisions and anticipate potential issues in their operations.

- Initial Investment Cost: The upfront cost of fiber laser cutting machines can be higher than that of traditional cutting technologies.

- Material Limitations: Although fiber lasers are versatile, there are certain materials, particularly very thick metals, where alternative cutting methods may be more efficient.

- Technical Complexity: Despite being user-friendly, the sophisticated technology behind fiber lasers can sometimes require technical support for optimization and troubleshooting.

Conclusion

Fiber laser cutting technology stands out for its precision, efficiency, and versatility, offering substantial advantages over traditional cutting methods.

Its ability to cut delicate materials, customized applications, and long-lasting performance make it a valuable asset for industries aiming for high-quality and efficient production.

However, considering the technology’s limitations is crucial for businesses looking to integrate fiber laser cutting into their operations effectively.

ACCURL’s contribution to this field, with its high-precision, high-energy fiber laser cutters, showcases the specific advantages that modern technology brings to the industry.

With features like ultra-fast positioning speeds of up to 180m/min and accelerations of 3G, combined with the long lifespan of their laser sources, ACCURL machines exemplify the advancements in fiber laser technology. The annealing of their steel frames to relieve stress ensures durability, supporting years of heavy use without distortion.

Moreover, the integration of ACCURL machines with automation modules demonstrates a forward-thinking approach to manufacturing, streamlining the production process and enhancing overall efficiency. This combination of speed, precision, and durability positions ACCURL’s fiber laser cutting systems as an excellent choice for businesses looking to leverage the full potential of modern laser cutting technology.