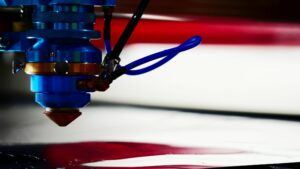

Laser cutting machines, synonymous with precision and versatility, have redefined the manufacturing industry. With varying prices, understanding the factors that influence their costs is essential. In this article, we will delve deep into the world of laser cutting machines and break down the complexities of their pricing.

What is a Laser Cutting Machine?

A laser cutting machine utilizes a high-powered beam to cut materials ranging from metal to wood. These machines ensure precision, leading to minimal waste and unmatched accuracy in the manufacturing and hobbyist sectors alike.

What is the Average Price of a Laser Cutting Machine?

The cost of a laser cutting machine can range anywhere from $3,000 to over $1 million, based on various factors discussed in the subsequent sections. This broad range might seem overwhelming, but understanding the influencing elements can guide a buyer to the perfect machine for their needs.

What are the Factors that Influence the Price of a Laser Cutting Machine?

Each factor plays a crucial role in determining the cost of the machine:

Laser Type

Different types of lasers, such as CO2, fiber, and diode, have distinct functionalities and, consequently, varying prices.

While CO2 laser cutting machines are known for their versatility, especially with non-metals, fiber laser cutting machines have grown in popularity for their efficiency in metal laser cutting tasks. Diode laser cutters, on the other hand, offer a balance between these types. The specific type of laser greatly influences the machine’s cost, functionality, and areas of application.

- CO2 Lasers: Especially efficient for materials like acrylic, MDF, and fabrics. CO2 laser machines provide quality cuts and engravings.

- Fiber Lasers: These are the go-to for metal laser cutting. Fiber laser machines excel in operations that involve metals like stainless steel and carbon steel.

- Diode Lasers: Ideal for beginner hobbyists, diode laser cutters offer a less powerful but more cost-effective solution for smaller projects.

Features

Advanced features like intuitive user interfaces, built-in design software, and safety measures can escalate the price.

Power Output

The power output of a laser cutting machine, typically measured in kilowatts (kW), directly correlates with its capabilities.

Higher power outputs allow for cutting thicker materials and faster operations, making fiber laser cutting particularly efficient for sheet metal fabrication. However, this increased capability often comes at a premium, affecting the laser cutting machine cost.

Size

Laser cutters come in various sizes, from compact desktop laser cutters suitable for small businesses and hobbyists to large industrial laser cutting equipment designed for mass production.

The machine’s size, directly impacting the work area, often has a proportional relationship with its price. Bigger machines, catering to industrial needs, naturally cost more due to their enhanced capacity and robust build.

Number of Axes

When it comes to intricate designs, precision is paramount. The spot diameter of a laser cutter determines its precision level. Machines with high precision capabilities often command higher prices. Another factor contributing to the cost is the number of axes. A machine with multiple axes provides flexibility for creating complex designs but is generally more expensive.

Cutting Speed

Furthermore, cutting speed is vital for businesses targeting mass production. Faster machines, designed for quick turnovers, typically have a higher price tag.

Work Table Size

The work table size dictates the scale of materials the machine can accommodate. Machines with larger tables, ideal for larger projects or batch processing of smaller items, are typically pricier.

Additionally, certain materials demand specific laser types. A machine’s ability to handle a variety of materials, from metals like brass and aluminum to non-metals like glass and wood, can also add to its cost.

Precision (Spot Diameter)

Precision is paramount for intricate designs. Machines with high precision usually have a steeper price tag.

Properties of the Workpiece Material

Certain materials require specific laser types. The more versatile the machine, the more expensive it usually is.

After-sale Support and Services

After-sale services play a crucial role in the overall value a buyer receives. Premium brands often extend comprehensive after-sales support, from training sessions to periodic maintenance checks. Such services can be essential, especially for beginner operators, but might increase the initial purchase price.

However, the long-term benefits, including extended machine lifespan and operational efficiency, can justify the costs.

Brand

The brand of a laser cutting machine can significantly influence its price. Established brands, renowned for their reliability, durability, and cutting-edge technology, often come at a premium.

Machines from manufacturers like Boss Laser and Flux Beamo have carved out their market share thanks to their consistent performance and customer support.

Automation Level and Capabilities

Modern laser cutters are increasingly integrating automation and advanced features. Aspects like auto-focus, material recognition, and computer-controlled settings not only enhance the user experience but also improve the machine’s efficiency and precision.

Naturally, these state-of-the-art features elevate the price. Yet, for many businesses, the benefits these features offer in terms of time savings, reduced waste, and product quality make the investment worthwhile.

How Much Do Different Laser Cutting Machines Cost?

When delving into the world of laser cutting machines, it’s evident that different types cater to varying needs, from hobbyists to industrial professionals. The price of these machines is heavily influenced by their design, capabilities, and the specific tasks they’re engineered for.

How much does a CO2 laser cutter cost?

CO2 laser cutters, ideal for non-metal materials, typically range from $8,000 to $50,000, with power outputs of 100W to 500W.

When you invest in a CO2 laser cutter, you are essentially paying for the efficient design and cutting technology that offers fine detail and precision, especially when working with materials like wood, acrylic, and fabric.

How much does a fiber laser cutter cost?

Fiber laser cutters, optimized for metals, have a price bracket of $20,000 to $500,000.

With power outputs ranging between 500W and 20kW, fiber laser cutters exhibit exceptional ability when processing metals like aluminum, brass, and stainless steel.

How much does a diode laser cutter cost?

Diode laser cutters make an affordable choice for many businesses, with prices hovering between $5,000 and $20,000.

These machines deploy semiconductor diodes, producing a laser beam to cut and engrave a variety of materials. They offer a mid-level power range, making them suitable for both beginner and intermediate operations.

How much does a Nd: YAG Laser Cutting Machine cost?

Nd: YAG laser cutters, ranging from $40,000 to $300,000, represent an investment in versatility.

Harnessing the power of neodymium-doped yttrium aluminum garnet crystals, these laser machines handle a variety of materials from metals to plastics. Their adaptability justifies their steeper price point, making them a favorite among industries seeking multipurpose cutting solutions.

How much does an entry-level laser cutting machine cost?

Entry-level laser cutting machines are designed for beginners or small businesses with limited requirements. These machines typically have a power range of 0.5 to 2 kW.

- Price Range: $3,000 – $10,000

- Power Range: 0.5 kW – 2 kW

How much does a hobbyist laser cutting machine cost?

Hobbyist laser cutting machines offer a balanced combination of power and affordability, making them ideal for personal projects and craft enthusiasts.

- Price Range: $500 – $3,500

- Power Range: 0.5 kW – 1.5 kW

How much does a small laser cutting machine cost?

Small laser cutting machines are optimal for businesses that require a compact, efficient, and budget-friendly option.

- Price Range: $2,000 – $15,000

- Power Range: 1 kW – 3 kW

How much does a mid-range laser cutting machine cost?

These machines strike a balance between the capabilities of entry-level and industrial models, catering to businesses that need advanced features without the colossal price tag of industrial machines.

- Price Range: $10,000 – $50,000

- Power Range: 2 kW – 10 kW

How much does an industrial laser cutting machine cost?

Industrial laser cutting machines are beasts in the manufacturing sector. They handle heavy-duty tasks, processing metals like stainless steel and carbon steel with ease.

- Price Range: $20,000 – $500,000

- Power Range: 3 kW – 30 kW

How much does a metal laser cutting machine cost?

Metal laser cutting machines are tailored for precision, accuracy, and durability when working with metals. They play a pivotal role in metal fabrication industries.

- Price Range: $15,000 – $300,000

How much does a tube laser cutting machine cost?

Tube laser cutting machines, as the name suggests, specialize in cutting tubes, providing clean and precise cuts for industries like furniture and automotive manufacturing.

- Price Range: $30,000 – $200,000

What are the costs of owning a laser cutting machine?

Ownership of a laser cutting machine is not just about the initial investment. There are several associated costs, which can vary based on the machine’s purpose and usage frequency.

Initial investment

The upfront cost of the laser cutter is a substantial part of the total ownership cost. This encompasses the machine’s price, installation, and any initial training required.

Storage Costs

Proper storage ensures longevity. Whether it’s renting space or creating an environment-controlled section in an existing facility, the costs can add up.

Materials

Laser cutting operations require specific materials, such as metals, acrylic, and even certain gases. Sourcing quality materials at competitive prices is essential to manage costs.

Maintenance

Regular maintenance is pivotal for optimal operation. This includes cleaning, recalibration, and, occasionally, parts replacement.

Consumables

Certain parts of a laser machine, like lenses or nozzles, might need frequent replacement, especially with intensive use.

Cost of staff and reaching ROI

Hiring skilled operators and technicians is crucial. Training and salaries are recurring expenses. Additionally, the time it takes to reach a return on investment (ROI) should also be factored in.

How much does a laser cutting machine cost per hour?

Operating costs per hour encompass electricity consumption, consumables, and potential labor costs. On average:

- Entry-level machines: $15 – $30 per hour

- Industrial machines: $100 – $200 per hour

However, depending on the type of laser used, the costs can vary significantly.

For instance, fiber laser cutting machines utilize a laser beam generated by banks of diodes, housed in compact modules. This beam, amplified through fiber-optic cables, retains its power and quality throughout its journey. CO2 laser cutting machines, on the other hand, rely on a mix of gases and a more energy-intensive generation process. This distinction in laser technology significantly impacts the overall costs.

The Role of Electricity Consumption

Electrical power consumption plays a pivotal role in the operational costs. The efficiency of a laser type can greatly influence the electricity bills for businesses.

Fiber lasers are known for their superior wall plug efficiency, often surpassing 40 percent. This means they not only utilize less power but also help in conserving valuable workspace by reducing the need for large chillers, unlike the CO2 lasers which require more overall power.

- Fiber lasers: These lasers are known for their efficiency. They typically have a wall plug efficiency of more than 40 percent, meaning they convert a higher portion of the electrical input into laser energy. Depending on the power output, they can cost between $1 to $5 per hour in electricity.

- CO2 lasers: CO2 lasers are larger and require more energy. Their efficiency is lower than fiber lasers, leading to electricity costs ranging from $4 to $12 per hour depending on the laser power and model.

- Diode lasers: Often used for engraving rather than cutting, these lasers consume less power than CO2 lasers but are generally less efficient than fiber lasers. The electricity costs can vary from $2 to $6 per hour.

Consumables

Another key factor in the running costs of laser cutting equipment is the consumables. For example:

- Laser tubes: Over time, laser tubes degrade and need replacement. The frequency of this replacement can influence costs. For instance, a CO2 laser tube may need replacement every 1,000 to 1,500 hours of use. The cost of a new tube can range from $200 to $2,000, depending on the machine and manufacturer.

- Lenses and mirrors: Essential for directing and focusing the laser beam. Wear and tear on these components can affect performance and eventual replacement costs. Cleaning is necessary, but eventual replacement is inevitable. A set can cost anywhere from $100 to $500.

- Cooling system: High-power laser cutting machines require cooling. Water chillers or other cooling systems might need occasional maintenance, which can incur costs of $100 to $500 annually.

- Cleaning and maintenance materials: Regular maintenance ensures the machine operates at peak efficiency. Materials used for cleaning can add to the operational costs.

Labor: A Significant Component

While machines have automated many processes, human intervention remains essential. The skill level of the operator can influence the hourly cost. A seasoned operator might achieve tasks faster and more efficiently than a beginner. Training for operators also becomes a consideration.

- Beginner operators: May require more time and resources, affecting hourly costs.

- Experienced operators: Can optimize processes and reduce wastage, leading to potential savings.

Material Being Processed

The type of material being cut or engraved, be it metal plates, acrylic, wood, or fabrics, can affect the wear on machine parts, impacting maintenance frequency and costs.

Metals, for example, might demand higher laser power, while materials like eva foam or rubber could be processed at lower settings.

How to choose a laser cutting machine?

Selecting the right laser cutting machine involves a thorough analysis of requirements, budget, and potential future needs. Here are some aspects to consider:

- Type of laser: There are several types, like CO2 lasers, diode lasers, and fiber lasers. Each has its advantages and applications.

- Material compatibility: Ensure the machine can handle the materials you typically work with, be it metal, acrylic, wood, or any other material.

- Power Output: Machines with higher power outputs can cut thicker materials at faster rates. However, they tend to be more expensive both in initial cost and operational expenses.

- Accuracy and Precision: Crucial for industries where minute details matter. The precision of laser cutters varies based on the model and manufacturer.

- Budget: Like any investment, it’s essential to balance between needs and available funds.

- Manufacturer Reputation: Researching the manufacturer can provide insights into the machine’s quality and reliability. For instance, ACCURL has 33 years of experience in the sector, producing high-precision 2D fiber laser cutters for industries. Their machines, which have critical parts manufactured in Germany, offer power from 1 kW to 30 kW. With over 12,000 installed machines and a committed R&D team, they also provide a 3-year warranty for their laser cutting machines, underscoring their confidence in the product.

Conclusion

The landscape of laser cutting machines is vast and varied. From hobbyists to heavy industries, there’s a laser cutting solution for every need. By considering the machine’s type, materials it can process, its power, and the reputation of the manufacturer, one can make an informed decision that caters to both present and future requirements.