Laser beam machining (LBM) represents a pivotal advancement in the realm of manufacturing, heralding a new era of precision and efficiency. This technology has evolved significantly since its inception, driven by the genius of pioneering inventors and critical milestones. It has reshaped the landscape of modern manufacturing, offering unparalleled precision and versatility.

LBM’s journey, from a novel concept to a cornerstone in advanced manufacturing, is a testament to human ingenuity and the relentless pursuit of perfection. This evolution has been marked by significant technological breakthroughs and the integration of sophisticated computer systems, enhancing its capabilities and applications. The result is a tool that not only transforms materials but also the very way we approach manufacturing.

What is Laser Beam Machining?

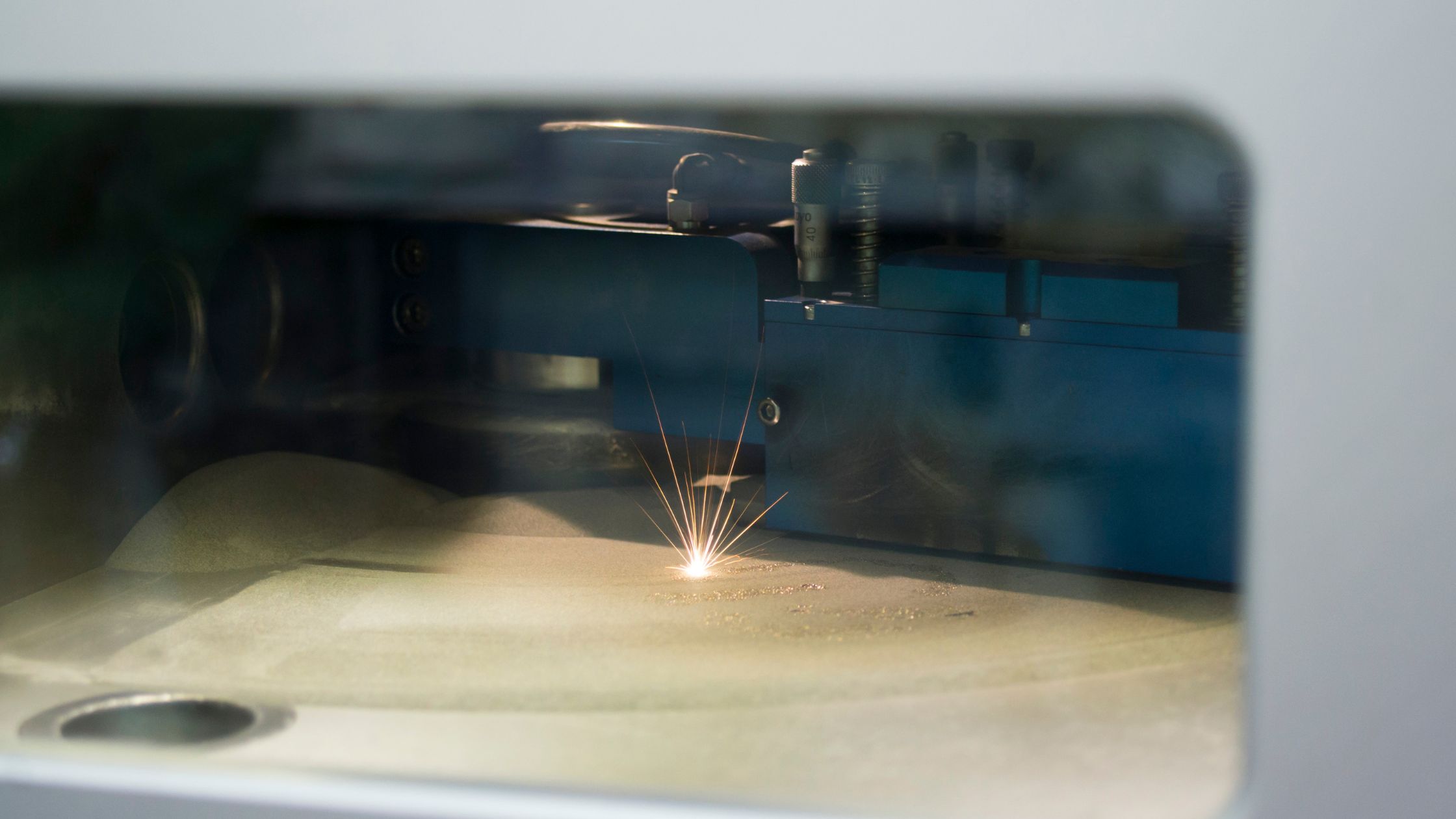

At its core, laser beam machining is a non-contact machining process that utilizes the intense energy of a laser beam to cut, drill, or engrave materials. A laser, which stands for Light Amplification by Stimulated Emission of Radiation, is essentially a device that emits a highly concentrated beam of light. In LBM, this laser light is directed towards a workpiece, where it applies localized heat and energy, resulting in precise material removal or alteration.

This process can be likened to a highly focused and controlled form of light, capable of achieving accuracy and intricacies unattainable by traditional machining methods. It’s a symphony of physics, optics, and engineering, coming together to create a tool that’s both powerful and precise.

Who Invented Laser Beam Machining?

The invention of laser beam machining is a testament to human innovation in the field of manufacturing. While the concept of lasers was first theorized by Albert Einstein in 1917, it wasn’t until 1960 that the first operational laser was created by Theodore H. Maiman.

This invention laid the groundwork for the development of laser beam machining, which has since undergone numerous advancements and adaptations, revolutionizing the way we approach material processing.

How Does Laser Beam Machining Work?

Laser beam machining (LBM) is a marvel of modern manufacturing, utilizing the concentrated power of laser beams to achieve precise material removal. This section breaks down the working principle of LBM into an easy-to-understand, step-by-step process:

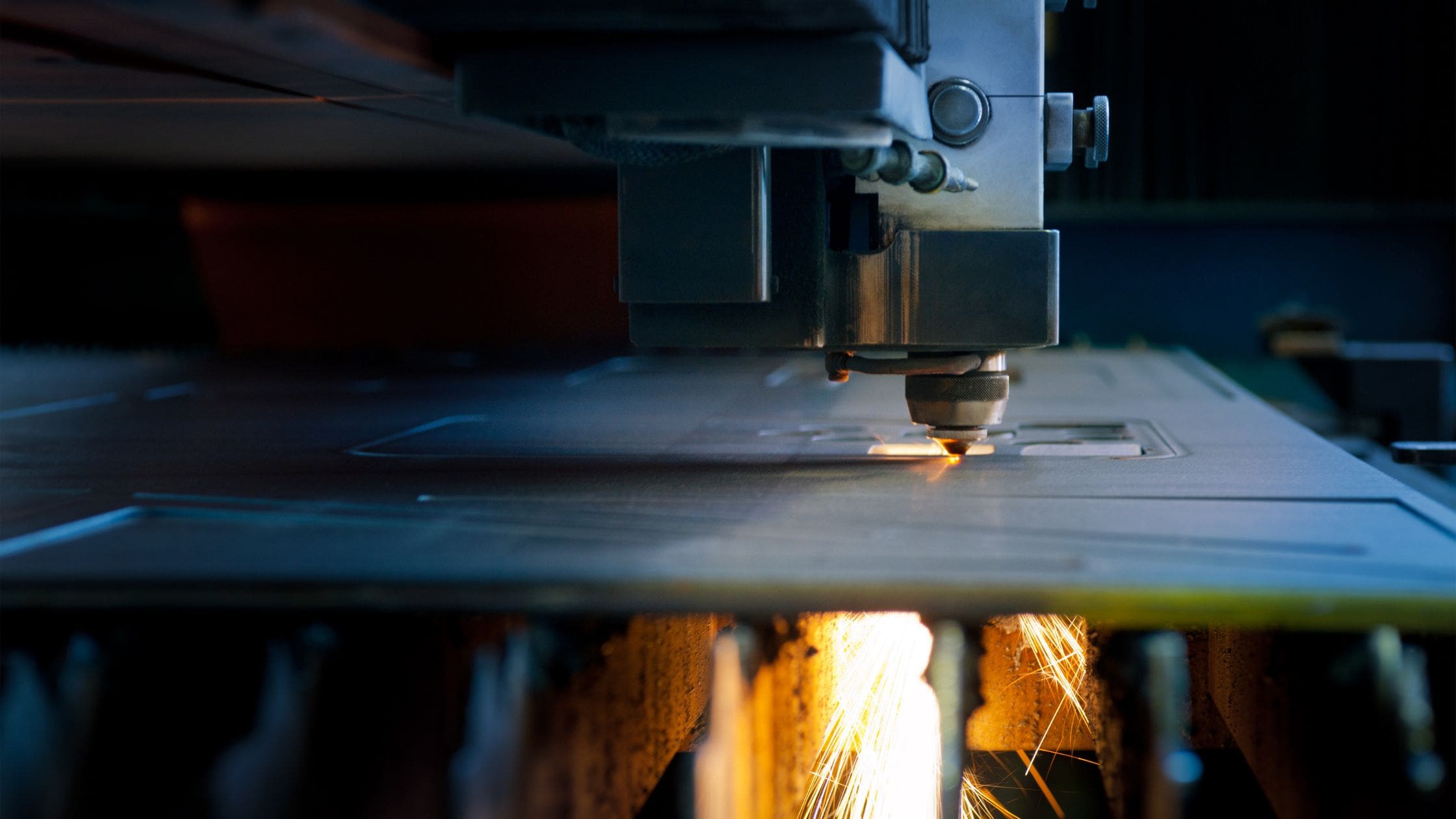

- Laser Generation: The process starts with the creation of a laser beam. In devices like CO2 lasers, electricity excites a gas mixture, producing laser light. In fiber lasers, diodes generate the light, which is then amplified through fiber optics.

- Beam Manipulation: Once generated, the beam is manipulated using mirrors and lenses. This shaping and focusing of the laser beam are crucial for achieving the desired machining effect on the workpiece.

- Material Interaction: The laser beam then interacts with the material, where its high energy density causes the material to heat up, melt, or vaporize. This interaction is finely controlled to achieve precise cuts or engravings.

- Process Control: Advanced computer systems manage the entire process, ensuring precision and repeatability. These systems control the laser’s movement, power, and focus, adapting to different materials and machining requirements.

Types of Lasers Used in Machining

In laser beam machining, a variety of laser types are employed, each suited for specific applications. The choice of laser depends on several factors, including the material being machined, the desired precision, and the specific machining process.

CO2 Lasers: Versatility in Laser Machining

CO2 lasers are among the most widely used lasers in machining, known for their versatility and power. They typically operate within a range of several kilowatts, making them suitable for cutting and engraving a variety of materials, including metals, plastics, and glass. Their functionality involves exciting a gas mixture (including carbon dioxide) to produce the laser beam, which is then focused on the workpiece for machining.

Nd:YAG Lasers: Precision and Power

Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) lasers emit light in the near-infrared region of the spectrum (typically around 1064 nm). These lasers are known for their high power and ability to operate in both continuous and pulsed modes, making them ideal for applications that require deep penetration and precision, such as drilling and cutting in the aerospace and automotive industries.

Fiber Lasers: The New Era of Laser Machining

Fiber laser cutting represents a more recent advancement in laser cutting technology. A fiber laser cutter generates laser light through banks of diodes and amplifies it using a fiber optic medium. With a wavelength range typically around 1070 nm, they offer advantages in terms of efficiency, maintenance, and beam quality. Fiber lasers are increasingly popular in precision machining, particularly in fine cutting and engraving applications.

What are the Components of a Laser Beam Machining System?

A laser machining system comprises several key components, each playing a crucial role in its operation. Understanding these components provides insight into how laser machining systems function as a cohesive unit.

Power Supply: The Heartbeat of Laser Machining Systems

The power supply is a critical component of any laser machining system, providing the necessary energy to generate the laser beam. It must be compatible with the specific type of laser being used and capable of delivering the required voltage range for efficient operation. The power supply’s specifications directly influence the performance and capabilities of the laser machining system.

Flash Lamps: The Catalysts in Laser Generation

Flash lamps in laser systems, particularly in solid-state lasers like Nd:YAG, are crucial. They provide the initial light energy needed to excite the laser medium, which in turn generates the laser beam. The efficiency of these lamps directly affects the laser’s performance, especially in terms of pulse duration and energy density.

Capacitor: Storing Energy for Optimal Laser Performance

Capacitors in a laser system act as energy reservoirs. They store electrical energy and release it rapidly to create the intense light pulses required for laser generation. The capacity and discharge rate of these capacitors are key factors in determining the power and frequency of the laser pulses, directly impacting the machining process.

Reflecting Mirror: Guiding Laser Beams with Precision

Reflecting mirrors are integral to directing and focusing the laser beam onto the workpiece. They must be precisely aligned and made of materials that can withstand high energy densities without degrading. The quality of these mirrors is critical for maintaining the laser beam’s integrity and accuracy.

Lenses: Focusing the Laser for Precision Machining

The lenses in a laser machining system are responsible for focusing the laser beam onto the workpiece. The material and curvature of these lenses determine how the laser light is concentrated, affecting the machining quality. Lenses must be chosen and maintained carefully to ensure optimal focus and minimal distortion.

Workpiece: Centerstage in Laser Machining

The workpiece is the material being machined. Its properties, such as material type, reflectivity, and thermal conductivity, play a significant role in how it interacts with the laser beam. Understanding these properties is essential for optimizing the machining process and achieving desired results.

What are Key Parameters in Laser Beam Machining?

Laser beam machining is governed by several key parameters, each contributing to the process’s efficacy and outcome. These include beam power, cutting speed, and focus, all of which must be finely tuned for optimal performance.

Beam Power and Its Impact

The power of the laser beam, typically measured in Watts, is a critical factor in laser machining. Higher power levels allow for quicker material removal but can also increase the heat affected zone, potentially affecting precision. Selecting the right power range for a given material is essential for balancing efficiency with quality. Here is a breakdown:

- Low Power Range (10-500 Watts): Ideal for thin materials and delicate operations like engraving or cutting thin plastics, fabrics, and foils. This range ensures minimal thermal damage to the workpiece.

- Medium Power Range (500-2,000 Watts): Suited for moderate thickness materials, such as medium-gauge metals and thicker plastics. It balances speed with precision, making it a versatile choice for various applications.

- High Power Range (2,000 Watts and above): Used for thick and dense materials, like stainless steel and titanium, often found in the aerospace and automotive sectors. High power enables faster cutting speeds but requires careful management to avoid excessive heat build-up and material warping.

Cutting Speed

Cutting speed, expressed in meters per second, is another vital parameter. Faster speeds can increase productivity but may compromise cut quality, especially in thicker materials. Conversely, slower speeds enhance precision but at the cost of longer machining times.

- Slow Speed (0.1-1 m/s): Recommended for intricate designs and high-precision cuts, especially in materials prone to thermal damage. This speed range is essential for applications requiring fine details and smooth edges.

- Moderate Speed (1-10 m/s): Balances precision and productivity. Commonly used in industrial applications where both quality and throughput are important.

- Fast Speed (10 m/s and above): Ideal for high-volume production where speed is a priority. Suitable for materials that can withstand higher thermal stress and for operations where fine details are less critical.

Tolerances in Laser Beam Machining

Precision and accuracy are paramount in laser beam machining (LBM), and tolerances play a crucial role in determining the suitability of LBM for various applications. Tolerances refer to the permissible limit or variation in a physical dimension or measured value, indicating how closely a machine can match the desired outcome. Here are some specific tolerance values commonly achieved in LBM:

- General Manufacturing Tolerances: For standard applications, LBM typically achieves tolerances within ±0.1 mm to ±0.2 mm. This range is suitable for a majority of industrial applications where precision is important but not critical.

- High-Precision Manufacturing Tolerances: In industries where extreme precision is necessary, such as aerospace and medical device manufacturing, LBM can achieve tolerances as tight as ±0.025 mm to ±0.05 mm. This level of precision is essential for components that must fit together perfectly or where minute deviations could lead to failure.

- Ultra-Precision Manufacturing: For the most demanding applications, such as in some aerospace, optics, and microelectronics components, LBM can achieve tolerances within the range of ±0.005 mm to ±0.01 mm. This ultra-precision machining is often required for components that function in critical or high-stakes environments.

What are the Advantages of Laser Beam Machining?

Laser beam machining offers numerous advantages over traditional machining methods:

Precision and Accuracy

LBM achieves high levels of precision and accuracy, making it ideal for intricate designs and fine details.

- The ability to produce extremely fine features, down to micrometer scales, is invaluable in industries like electronics and microengineering.

- Consistent and repeatable precision, ensuring high-quality production over large volumes.

Speed

The process is faster than many conventional methods, enhancing productivity.

- Rapid processing time significantly reduces turnaround times, crucial in high-volume production and just-in-time manufacturing.

- The speed of LBM also contributes to lower production costs, as it reduces the time machines and labor are needed.

Versatility

LBM can be used on a wide range of materials, including metals, plastics, ceramics, glass, and composites.

- Its adaptability allows for its use in various industries, from aerospace to the medical field.

- The ability to easily switch between different materials and thicknesses without the need for tool changes enhances operational flexibility.

Non-contact Process

Being a non-contact method, it reduces tool wear and eliminates mechanical stresses on the workpiece.

- This aspect is particularly important for delicate or brittle materials that cannot withstand mechanical force.

- Minimized physical contact also means there is less risk of contamination, which is crucial in sectors like semiconductor manufacturing and food processing.

Energy Efficiency and Sustainability

Modern laser systems, especially fiber lasers, are known for their high energy efficiency.

- Reduced energy consumption not only lowers operational costs but also aligns with sustainable manufacturing practices.

- Minimal waste generation, as LBM can precisely remove material without excess scrap.

Enhanced Safety and Ergonomics:

With LBM, the risk of accidents associated with manual operation of traditional machining tools is significantly reduced.

- Automated laser systems improve workplace ergonomics, reducing the physical strain on operators.

- Safer working environments are created, as there is less interaction with sharp tools and heavy machinery.

Customization and Design Flexibility

LBM offers unparalleled flexibility in design, allowing for customization that would be difficult or impossible with traditional methods.

- Ability to create complex and unique geometries, including 3D shapes and intricate patterns.

- Offers designers and engineers more creative freedom, paving the way for innovation in product design.

What are the Applications of Laser Beam Machining Across Industries?

The versatility of laser beam machining (LBM) extends its application across a wide array of industries, each harnessing its precision and efficiency for various purposes:

Aerospace

- Manufacturing intricate components with high precision for aircraft and spacecraft.

- Customizing parts for satellite systems and space exploration equipment.

- Employing laser welding for strong, lightweight joint constructions.

- Precision drilling of micro-holes in high-stress components.

Automotive

- Producing complex parts with speed and accuracy for both internal and external vehicle components.

- Custom fabrication of lightweight materials to enhance fuel efficiency.

- Application in laser welding for robust chassis and bodywork assembly.

- Precise cutting for electric vehicle battery components and connectors.

Electronics

- Creating detailed components for electronic devices, including circuit boards and connectors.

- Laser etching of serial numbers and identification marks on sensitive electronic components.

- Precision cutting of thin materials for smartphones, tablets, and computers.

- Laser drilling of micro-vias in multilayer PCBs (Printed Circuit Boards).

Medical

- Fabricating precise instruments and implants with biocompatible materials.

- Customizing prosthetics and orthopedic implants through precise laser cutting.

- Employing laser machining for dental equipment and surgical tools.

- Crafting microscopic components for minimally invasive surgical instruments.

Energy Sector

- Utilizing laser machining for components in solar panels and wind turbines.

- Manufacturing parts for nuclear energy facilities with high-precision requirements.

- Laser cutting of pipelines and other infrastructure for oil and gas industries.

Research and Development

- Producing specialized components for laboratory equipment and experimental setups.

- Enabling the creation of custom parts for unique research projects and innovations.

Consumer Goods

- Customizing jewelry and luxury items with intricate designs and personalization.

- Utilizing laser engraving for branding and aesthetic enhancements on consumer products.

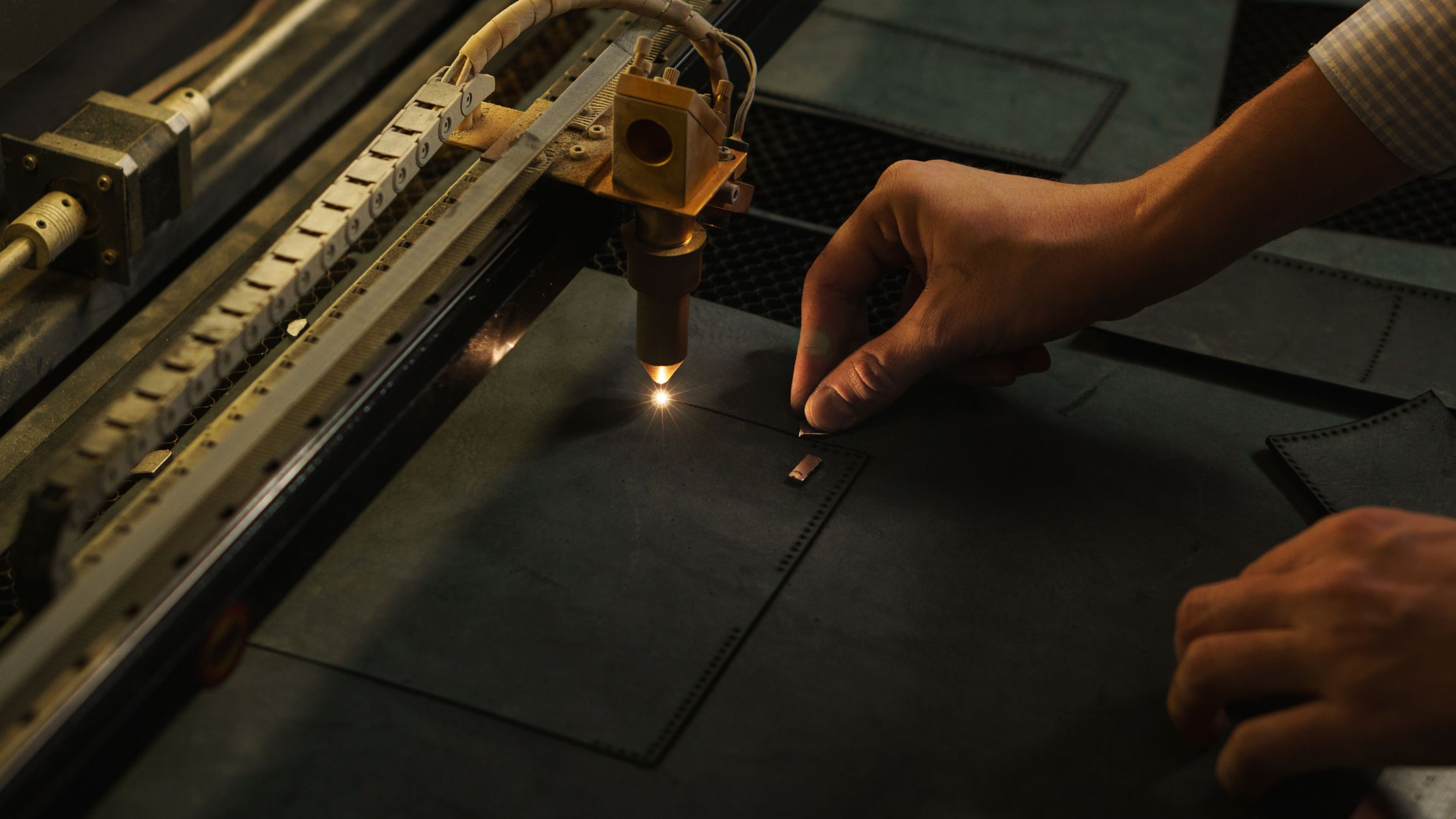

Textile Industry

- Implementing laser cutting for precise patterns and designs in fabrics.

- Enhancing production efficiency with automated laser machining processes.

Construction and Architecture

- Using laser machining for precise cutting of building materials like steel and glass.

- Facilitating the creation of complex architectural models and prototypes.

What Material Can Be Machined by Using Laser Beam?

Laser beam machining (LBM) is renowned for its versatility in handling a wide range of materials. This adaptability makes it an invaluable asset in various manufacturing processes, where different materials require precise and efficient machining. Here’s a more comprehensive list of materials suitable for LBM:

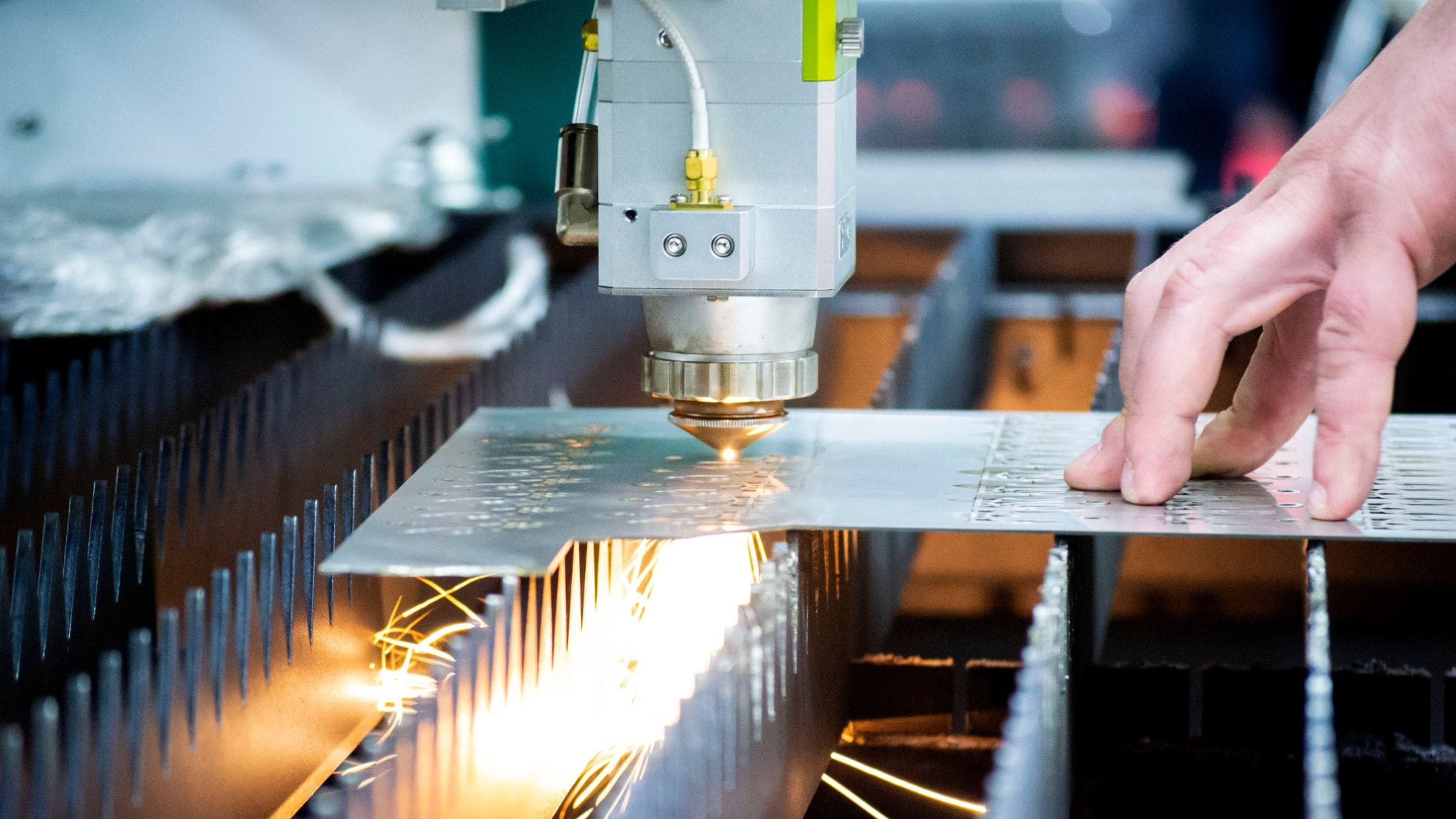

Metals

- Stainless steel: Known for its durability and corrosion resistance.

- Aluminum: Lightweight yet strong, ideal for aeronautics and automotive industries.

- Titanium: Offers high strength-to-weight ratio, used in medical implants and aerospace.

- Copper: Excellent electrical conductivity, used in electrical components.

- Brass: A combination of copper and zinc, used for decorative items and in plumbing.

- Nickel Alloys: Resistant to high temperatures and corrosion, used in energy sector components.

Non-metals

- Plastics: Acrylic, polycarbonate, and ABS, each with unique properties suitable for various applications.

- Ceramics: Including advanced ceramics used in high-temperature environments.

- Glass: Including borosilicate and soda-lime glass for intricate cutting and etching.

- Composites: Like carbon fiber-reinforced plastics, used in automotive and aerospace sectors.

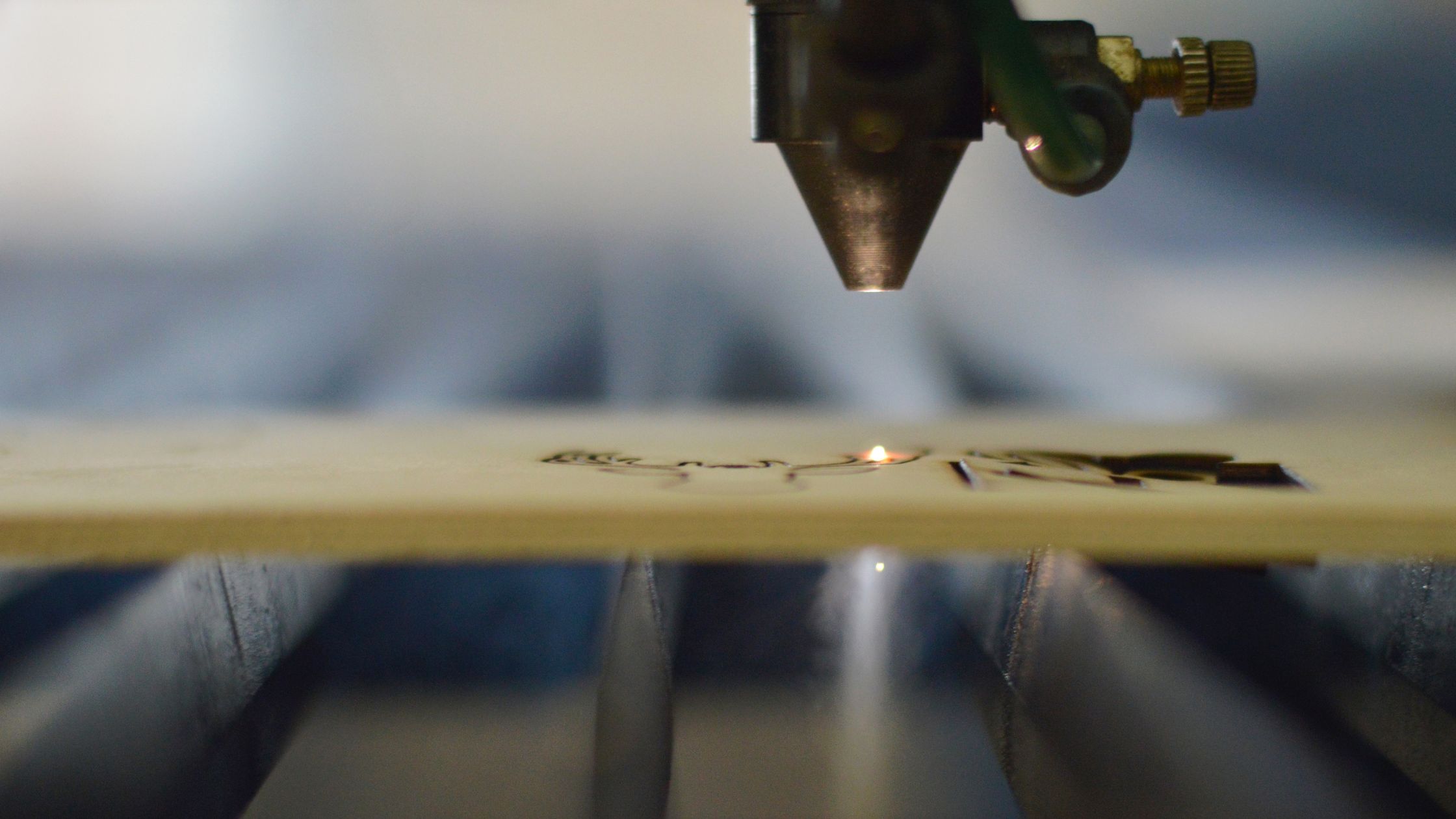

- Wood: For intricate designs and patterns in art and decor.

Specialized Materials

- Photomachinable glass: Used in microfluidics and other precision applications.

- Certain types of rubber: For custom gaskets and seals in various industries.

- Foam: Including polyurethane foam for packaging and insulation applications.

- Textiles: For precise cutting in fashion and industrial textiles.

Other Materials

- Leather: For precise cutting and engraving in fashion and upholstery.

- Stone and Marble: Used for decorative and architectural purposes.

- Paper and Cardboard: For intricate designs in packaging and art.

Challenges and Limitations in Laser Beam Machining

While laser beam machining offers numerous benefits, it also faces certain limitations that can impact its application in various industries.

Analyzing the High Initial Cost

One of the most significant challenges in implementing laser beam machining is the high initial cost. The investment required for setting up a laser machining system includes expenses for purchasing the laser source, associated components like lenses and power supply, and often a sophisticated computer control system.

These costs can range from tens of thousands to hundreds of thousands of dollars, depending on the system’s complexity and capabilities. Additionally, operational costs, including maintenance, power consumption, and occasional part replacements, add to the financial considerations.

Comparing Laser Beam Machining with Other Techniques

Laser beam machining stands apart in the field of material processing, offering unique advantages over other techniques. However, understanding its differences and similarities with methods like electron beam machining provides a comprehensive view of its capabilities and applications.

Laser vs. Electron Beam Machining

Laser and electron beam machining are both advanced material processing techniques, but they differ significantly in their working principles and applications:

- Energy Source: Laser machining uses concentrated light energy, whereas electron beam machining relies on a stream of electrons.

- Material Interaction: Laser machining is versatile, working on a wide range of materials, while electron beam machining is more specialized, often requiring a vacuum environment.

- Application Range: Laser machining is commonly used for cutting, engraving, and drilling, while electron beam machining finds its niche in welding and micro-machining applications.

What is the Difference Between Laser Beam Machining and Laser Cutting?

While often used interchangeably, laser beam machining and laser cutting are distinct processes:

- Laser Beam Machining involves removing material through vaporization or melting, often used for intricate and precise machining tasks.

- Laser Cutting primarily focuses on cutting materials to shape, laser cutting is typically faster and used for larger-scale production tasks.

Safety Protocols in Laser Beam Machining

Adhering to strict safety protocols is essential in laser beam machining:

- Protective Gear: Use of safety glasses and shields to protect against laser exposure.

- Training: Comprehensive training for operators on safe handling and emergency procedures.

- Workplace Safety: Implementing safe work practices to prevent accidents.

Conclusion

Laser beam machining stands as a testament to technological progress, continually evolving to meet the demands of modern manufacturing. Its precision, versatility, and adaptability make it an invaluable tool across various industries.